a filling valve

A filling valve and valve body technology, applied in the field of filling valves, can solve the problems of poor liquid seal and liquid leakage, and achieve the effect of simple installation and debugging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

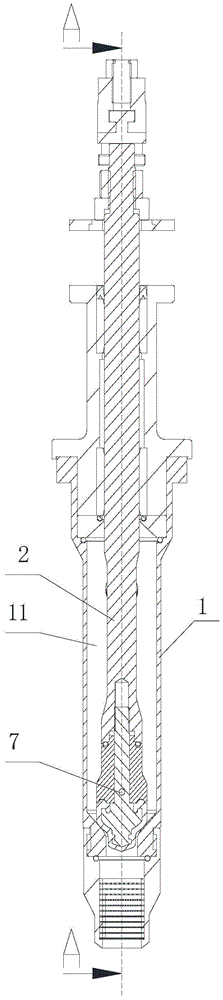

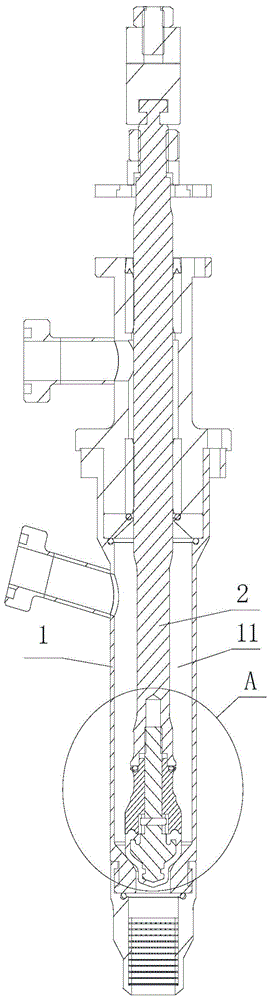

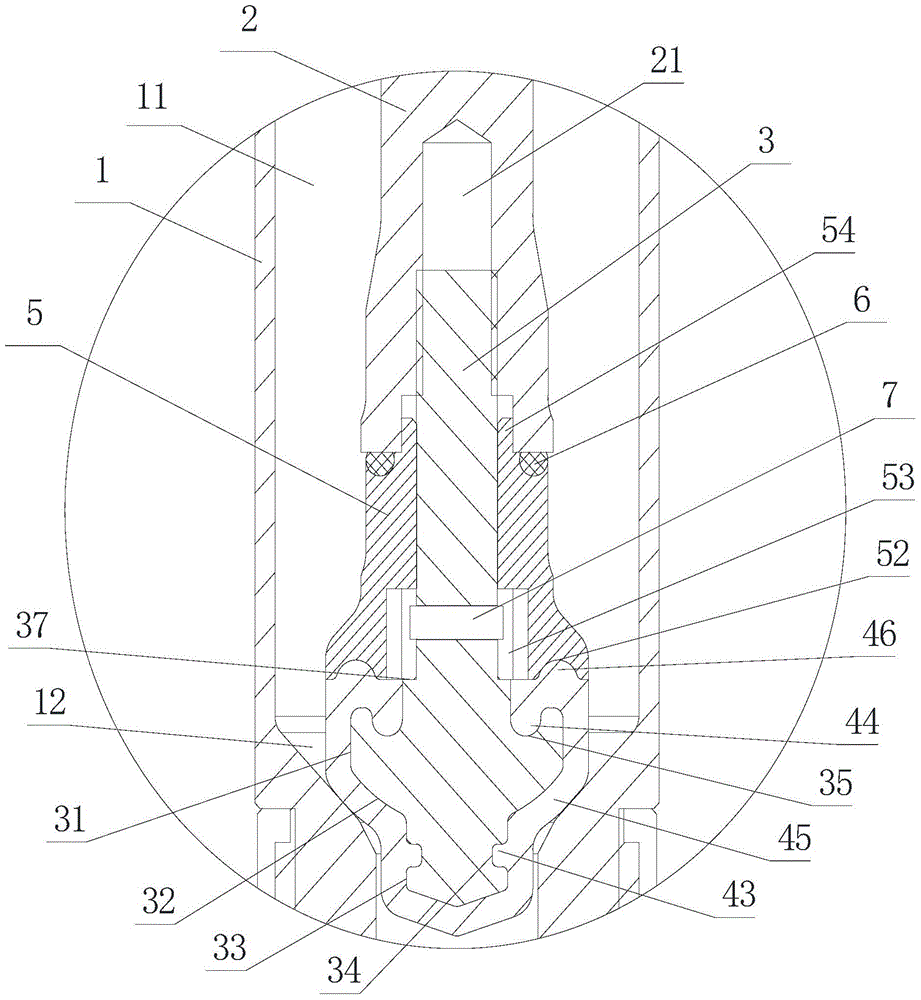

[0026] Such as Figures 1 to 11 Shown is an embodiment of a filling valve of the present invention, which includes a valve body 1 and a plugging rod 2. The valve body 1 has an inner cavity 11 that runs through the upper and lower ends of the valve body 1. The inner cavity 11 is a cylindrical cavity. The blocking rod 2 is located in the inner cavity 11, and the inner diameter of the valve body 1 gradually decreases at the bottom end of the inner cavity 11 to form a constriction 12, and the wall surface of the valve body 1 at the constriction 12 is a side structure of a circular platform; A sealing assembly consisting of a mounting part and a sealing sleeve 4 is installed. The sealing assembly is an axisymmetric structure as a whole. In the sealing assembly, the mounting part is wrapped in the sealing sleeve 4, and a hollow cavity is formed inside the sealing sleeve 4 to wrap the mounting part. 41. The bottom and sides of the sealing sleeve 4 are closed, and the top of the insta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com