Method for heat treatment of large-sized titanium alloy frame parts by virtue of special-shaped blocks

A titanium alloy and special-shaped block technology, which is applied in the field of heat treatment process for large titanium alloy frame parts, can solve problems such as deformation, affecting the quality of parts delivery, and reducing the progress of parts production and delivery.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] A heat treatment process for large titanium alloy frame parts by using special-shaped blocks, comprising the following steps:

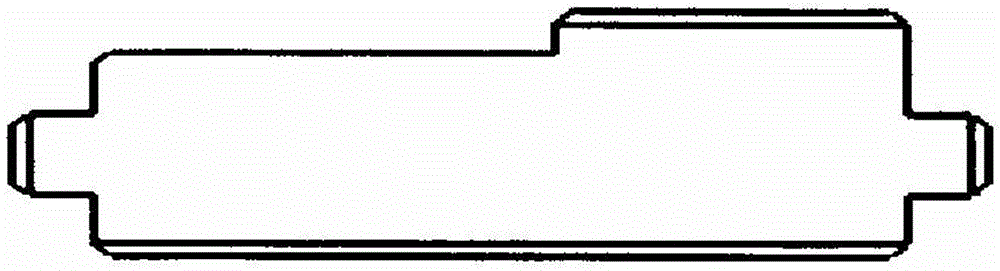

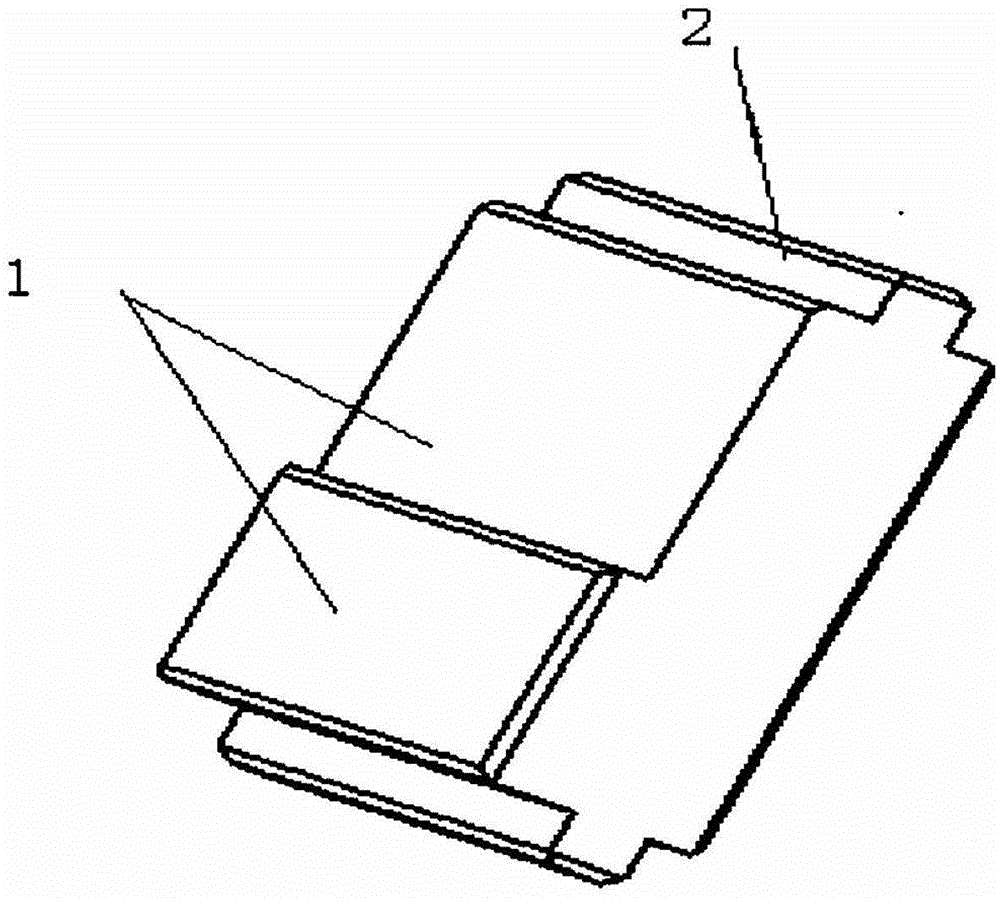

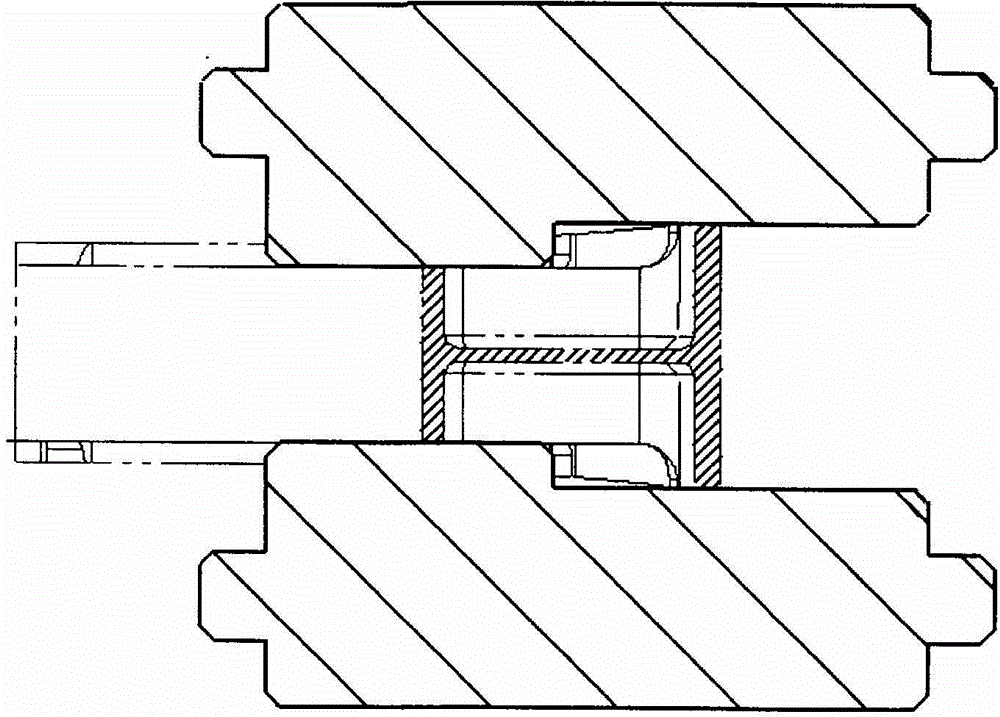

[0017] 1) if figure 1 and figure 2 As shown, process several special-shaped blocks: use 1Cr18Ni9Ti material to manufacture special-shaped blocks, design one side of the special-shaped block as a plane, and design the other side as a step 1, and the distance of the step is consistent according to the surface shape of the parts to be heat treated; at the same time Bosses 2 are respectively set at both ends of the special-shaped block for easy handling;

[0018] 2) Select a titanium alloy vacuum annealing heat treatment furnace with a flat furnace bottom plate for heat treatment, the heat treatment category is Class III (±10°C), and ensure that the temperature uniformity and system error are qualified within the validity period;

[0019] 3) Check the surface condition of the parts before loading the furnace, and clean the parts and the special-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com