Manufacturing method of marine crankshaft material and marine crankshaft manufactured by the method

A manufacturing method and crankshaft technology, which is applied in the manufacturing field of marine crankshafts and 42CrMoA marine internal combustion engine crankshaft forging materials, can solve the problem of not being able to produce a large amount of local deformation, and achieve the effect of low inclusion level

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

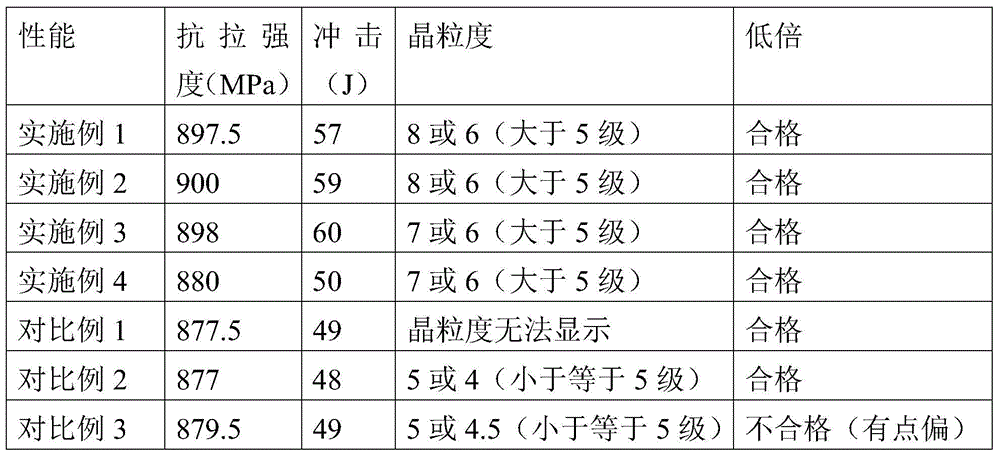

Examples

Embodiment 1

[0047] This embodiment is used to illustrate the manufacturing method of the marine crankshaft material of the present invention and the marine crankshaft manufactured by the method.

[0048] (1) Using the smelting process of electric furnace smelting + LF refining + VD vacuum degassing, and then casting at a temperature of 1530 ° C for 20 minutes (casting process of low temperature and slow pouring), based on the total weight of the obtained steel, wherein, The content of C is 0.42% by weight, the content of Mn is 0.72% by weight, the content of Si is 0.25% by weight, the content of P is 0.01% by weight, the content of S is 0.005% by weight, and the content of Cr is 1.19% by weight. The content is 0.21% by weight, the content of Ni is 0.44% by weight, the content of V is 0.08% by weight, the content of Cu is 0.10% by weight, and the content of iron is 96.575% by weight; after tapping, it is cast into 9t octagonal steel ingot;

[0049] (2) The temperature of the 9t octagonal s...

Embodiment 2

[0056] This embodiment is used to illustrate the manufacturing method of the marine crankshaft material of the present invention and the marine crankshaft manufactured by the method.

[0057] (1) Adopt the smelting process of electric furnace smelting + LF refining + VD vacuum degassing, and then cast at 1531°C for 22 minutes (casting process of low temperature and slow pouring), based on the total weight of the obtained steel, wherein, The content of C is 0.42%, the content of Mn is 0.72%, the content of Si is 0.22%, the content of P is 0.012%, the content of S is 0.005%, the content of Cr is 1.12%, the content of Mo is 0.22%, Ni The content of V is 0.43%, the content of V is 0.09%, the content of Cu is 0.10%, and the content of iron is 96.663% by weight; after tapping, it is cast into 9t octagonal steel ingot;

[0058] (2) The temperature of the 9t octagonal steel ingot is sent to the forging workshop to enter the heating furnace at a temperature of 500°C, and the holding ti...

Embodiment 3

[0065] This embodiment is used to illustrate the manufacturing method of the marine crankshaft material of the present invention and the marine crankshaft manufactured by the method.

[0066] (1) Using the smelting process of electric furnace smelting + LF refining + VD vacuum degassing, and then casting at a temperature of 1534 ° C for 19 minutes (casting process of low temperature and slow pouring), based on the total weight of the steel obtained, wherein, The content of C is 0.43% by weight, the content of Mn is 0.74% by weight, the content of Si is 0.27% by weight, the content of P is 0.009% by weight, the content of S is 0.006% by weight, and the content of Cr is 1.15% by weight. The content is 0.21% by weight, the content of Ni is 0.43% by weight, the content of V is 0.1% by weight, the content of Cu is 0.08% by weight, and the content of iron is 96.575% by weight; after tapping, it is cast into 9t octagonal steel ingot;

[0067] (2) The temperature of the 9t octagonal s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com