A blast furnace elevated pipeline wet injection system and method

A pipeline and high-level technology, which is applied in the field of blast furnace high-level pipeline wet injection system, can solve the problems of high conveying pressure and large pipeline loss, achieve uniform and rapid injection, reduce quantity and labor intensity, and improve injection efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

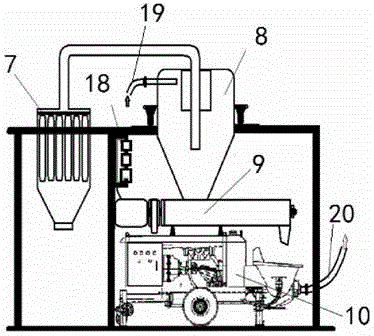

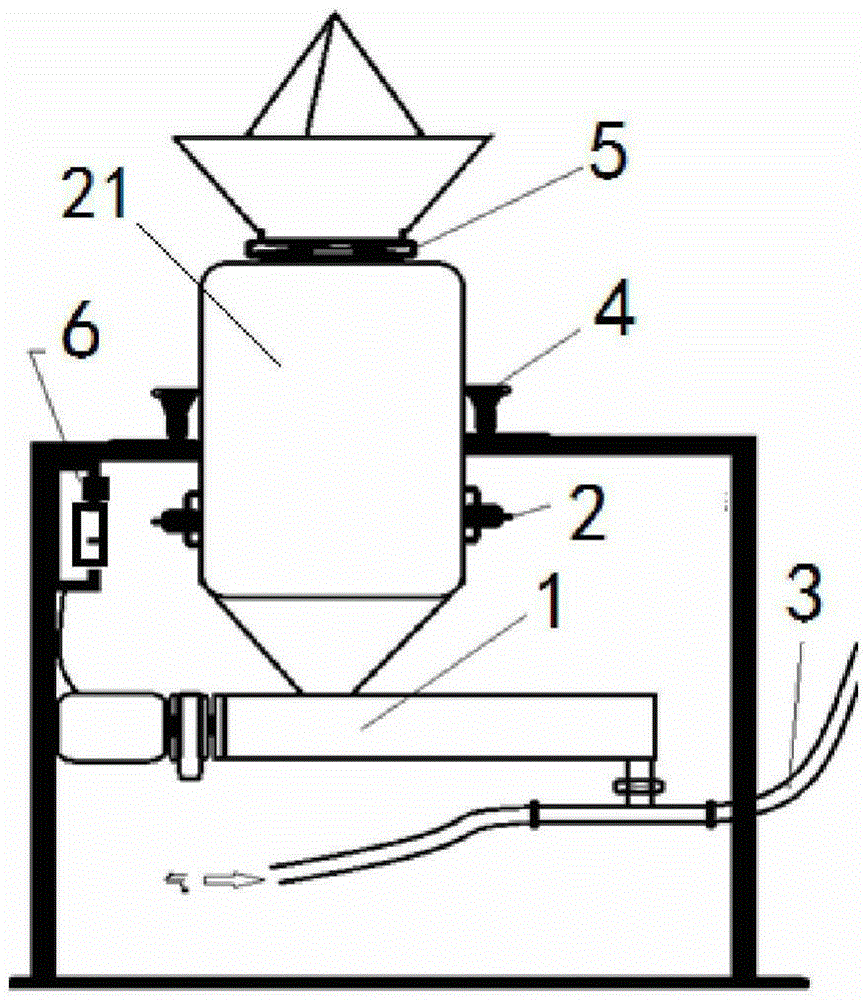

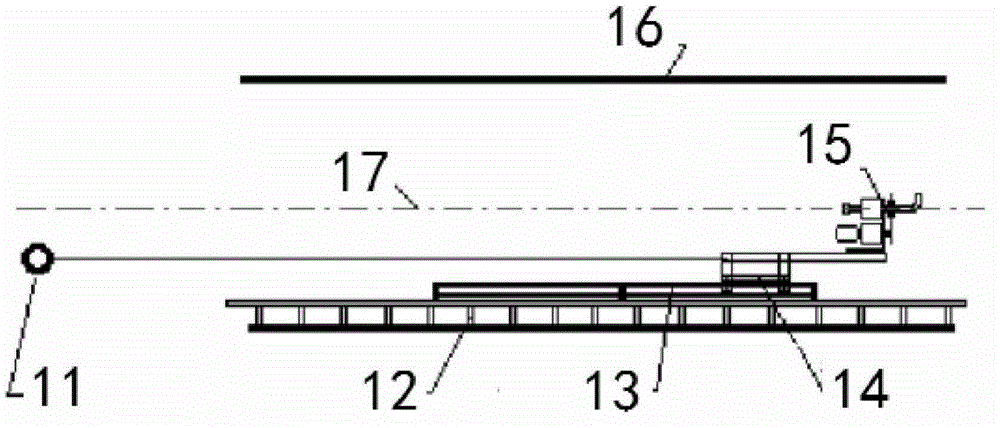

[0024] Embodiment 1: as figure 1 , figure 2 , image 3 and Figure 4 As shown, a high-level pipeline wet injection system for a blast furnace includes a set of high-level conveying equipment, a set of collecting equipment and pumping devices, and a set of rotary injection manipulators used in the pipelines of the in-pipeline rotary injection manipulator device.

[0025] The high-level conveying equipment includes a material tank system with a feed valve and a discharge screw, a pneumatic conveying system, a gravity monitoring system for the state of the material in the tank, a shock and vibration system to prevent the sticky material on the inner wall of the tank, and a PLC for controlling the screw discharge speed Electric control system.

[0026] The collection equipment and pumping device include a cyclone collection cylinder and a belt dust collection mechanism. The lower part of the cyclone dust collector is the collection bin, and the refractory material from the co...

Embodiment 2

[0032] Embodiment 2: as figure 1 , figure 2 , image 3 and Figure 4 As shown, a blast furnace high-level pipeline wet injection system, the gas material pipeline 3 of the high-level conveying equipment 100 is connected to the continuous mixer 9 of the collection equipment and the pumping device 200; the uniformly stirred wet material pipeline of the collection equipment and the pumping device 200 20 is connected to the rotary spray gun 15 of the rotary injection manipulator device 300 in the pipeline.

[0033] The discharge screw device 1 is connected to the gas pipeline 3 and the feed bin 21, the bin mouth of the feed bin 21 is connected to the feed valve 5, and the gravity monitoring device 4 is installed in the middle of the feed bin 21 and fixed on the shell, and the impact vibration The device 2 is connected to the middle and lower part of the feed bin 21, the first PLC control device 6 is fixed on the casing, and the first PLC control device 6 is connected to the di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com