Preparation method and application of chitosan-reduced glutathione polymer

A technology of glutathione and chitosan, applied in the direction of flocculation/sedimentation water/sewage treatment, etc., can solve the problem of inability to meet the needs of treatment, and achieve the effect of good removal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

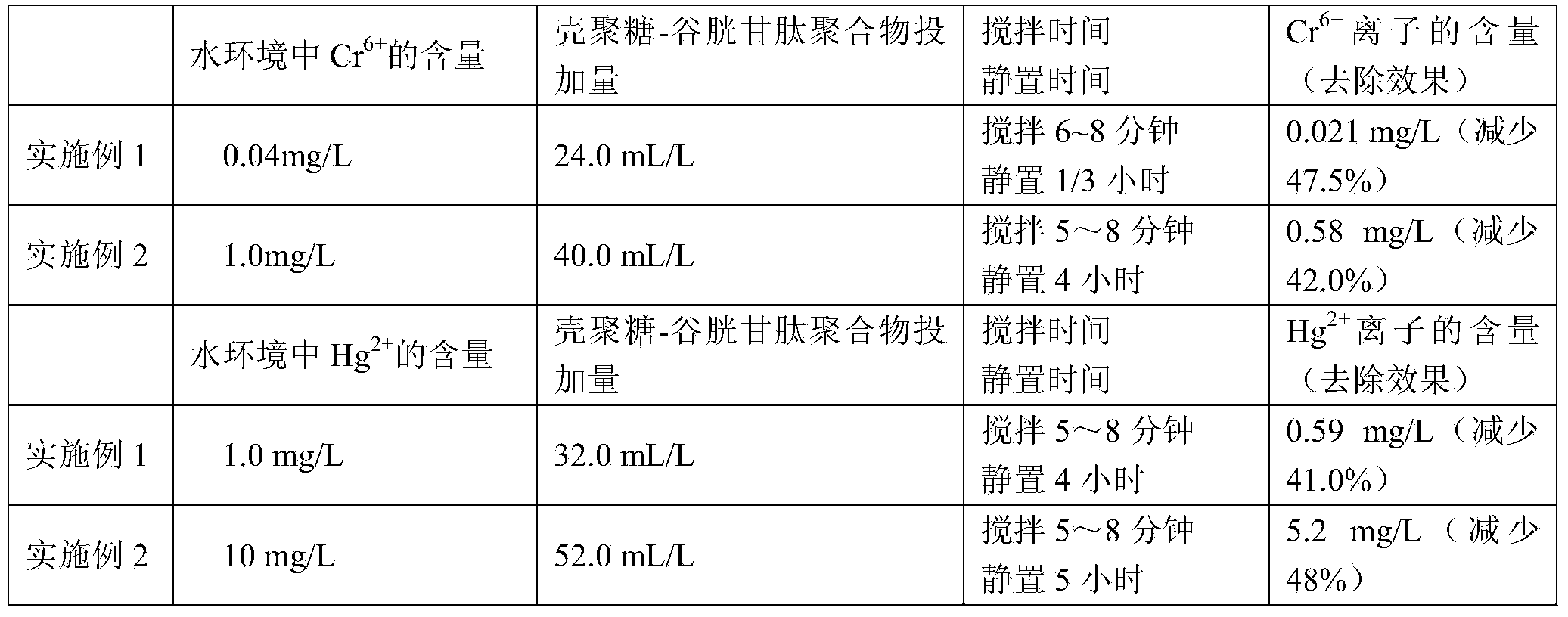

Examples

Embodiment 1

[0022] (1) at room temperature, add chitosan monomer 0.60g in reaction vessel, add the hydrochloric acid solution of the 1mol / L of 3.0mL and make chitosan fully swell;

[0023] (2) Add 50.0 mL of deionized water to fully dissolve;

[0024] (3) At room temperature, take 0.50 g of 1-ethyl-3-(3-dimethylaminopropyl) carboimide hydrochloride, 0.50 g of N-hydroxysuccinimide, and reduced glutathione 0.04g, fully dissolved with 5.0mL of deionized water respectively, added to the chitosan solution in turn, and the solution was mixed evenly;

[0025] (4) The pH value of the reaction system is adjusted to 5.0;

[0026] (5) The temperature of the reaction is controlled at 32° C., heated in a water bath;

[0027] (6) While heating in a water bath, continue the mechanical stirring reaction for 3 hours, and the rotating speed is 210r / min;

[0028] (7) After the reaction, the liquid product obtained is chitosan-reduced glutathione polymer.

Embodiment 2

[0030] (1) at room temperature, add chitosan monomer 0.60g in reaction vessel, add the hydrochloric acid solution of the 1mol / L of 3.0mL and make chitosan fully swell;

[0031] (2) Add 50.0 mL of deionized water to fully dissolve;

[0032] (3) At room temperature, take 0.50 g of 1-ethyl-3-(3-dimethylaminopropyl) carboimide hydrochloride, 0.50 g of N-hydroxysuccinimide, and reduced glutathione Put 0.04g into the same beaker, fully dissolve it with 15.0mL deionized water, then add it into the chitosan solution, and mix the solution evenly;

[0033] (4) The pH value of the reaction system is adjusted to 5.0;

[0034] (5) Place the reaction vessel in a microwave reactor, control the microwave power to 20W, and take it out after 1 minute of reaction;

[0035] (6) The reaction vessel is placed in a water bath, and the temperature is controlled at 35°C;

[0036] (7) While heating in a water bath, continue the mechanical stirring reaction for 5 hours, and the rotating speed is 200r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com