A kind of preparation method of citral

A technology of citral and dehydrolinalool, which is applied in the field of fine chemicals, can solve the problems of reduced catalyst activity, high catalyst cost, and reduced selectivity, and achieve the effects of fast conversion speed, reduced production cost, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] The preparation method of described citral, the catalyst used is molybdenum trioxide, heterogeneous catalysis. After the reaction is finished, the catalyst can be recycled by filtration, the reaction solution can be concentrated to obtain the citral product, and the final product can be obtained through rectification and purification.

[0030] The invention has high catalytic efficiency, good selectivity and fast transformation speed, and the reaction time is only 2.5-3 hours for complete transformation. The yield of citral can reach more than 95.8%.

Embodiment 1

[0032] A preparation method of citral, comprising the following steps:

[0033] a. Feeding

[0034] Put 100.0g of dehydrolinalool, 30.0g of dimethyl sulfoxide, 30.0g of acetic acid, and 300.0g of toluene into a 1000ml three-necked flask equipped with a stirrer, a thermometer, and a condenser, and simultaneously add 0.5g of molybdenum trioxide as a catalyst.

[0035] b. Response

[0036] Fully stir the input raw materials, raise the temperature to reflux, keep warm for reaction, control the reaction temperature at 80-140°C for reaction, and track and detect the reaction process by gas chromatography.

[0037] c, filtration, vacuum distillation

[0038] After the reaction was completed, the solid was filtered off, concentrated under reduced pressure and distilled under reduced pressure to obtain the finished product.

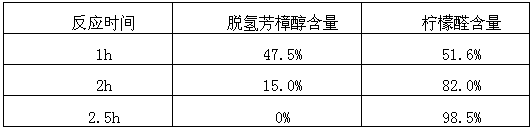

[0039] Gas chromatographic determination of content, the reaction results are as follows:

[0040]

[0041] According to the step of embodiment 1, change t...

Embodiment 2

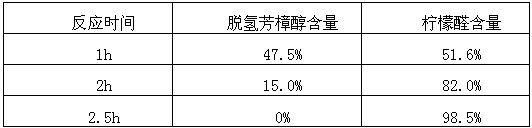

[0056]The recovery of catalyst is applied mechanically: the catalyst recovered after filtering the reaction solution of Example 1 is put into a 1000ml three-necked flask equipped with a stirrer, a thermometer, and a condenser tube, and 100.0g dehydrolinalool, 30.0g dimethyl sulfoxide, 30.0 1 g of acetic acid and 300.0 g of toluene were fully stirred, the temperature was raised to reflux, and the temperature was maintained for reaction, and the reaction process was tracked and detected by gas chromatography. After the reaction was completed, the solid was filtered off, concentrated under reduced pressure and distilled under reduced pressure. Measure content by gas chromatography, reaction result is as follows:

[0057]

[0058] It can be seen from the above table that the reaction effect is better after the catalyst is recovered and applied mechanically, and the citral content reaches 98.5%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com