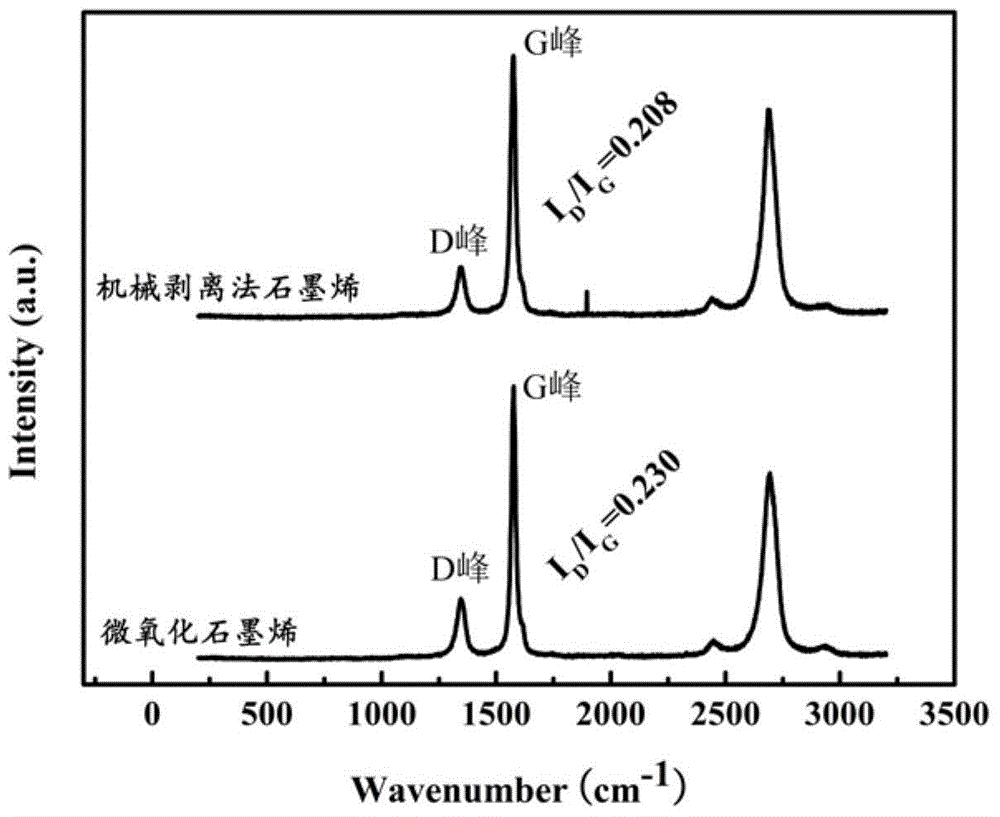

Micro-oxidized graphene and preparation method thereof

A graphene and fossil technology, applied in the field of micro-graphene oxide and its preparation, can solve problems such as unfavorable production and application, dangerous use process, long reaction time, etc., to overcome uncontrollable activation, high cost input, and lattice defects. less effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Mix 10g of mechanically exfoliated graphene, 50g of potassium hydroxide, and 500g of water, stir and ultrasonically for 1 hour to obtain a uniform viscous dispersion; transfer the dispersion to a crucible, place it in a microwave oven for 15 minutes; wash the microwaved product repeatedly with water and suction filtration to remove potassium hydroxide until the filtrate is neutral and dried to obtain a solid; weigh 5 g of the above solid, mix with 15 g potassium permanganate and 250 g water, react in the reactor for 2 hours, and set the reaction temperature to 150 °C After the reaction, the product is taken out, repeatedly washed with water and suction filtered to remove excess potassium permanganate, and dried to obtain a micro-graphene oxide product.

Embodiment 2

[0035] Mix 10g of mechanically exfoliated graphene, 40g of sodium hydroxide, and 200g of water, and stir for 1.5 hours with ultrasound to obtain a uniform viscous dispersion; transfer the dispersion to a crucible, and place it in a microwave oven for 15 minutes; wash the microwaved product repeatedly with water and suction filtration to remove sodium hydroxide until the filtrate is neutral and dried to obtain a solid; weigh 5 g of the above solid, mix with 15 g potassium permanganate and 250 g water, react in the reactor for 2 hours, and set the reaction temperature to 150 °C After the reaction, the product is taken out, repeatedly washed with water and suction filtered to remove excess potassium permanganate, and dried to obtain a micro-graphene oxide product.

Embodiment 3

[0037] Mix 10g of mechanically exfoliated graphene, 40g of potassium hydroxide, and 500g of water, stir and ultrasonically for 1 hour to obtain a uniform viscous dispersion; transfer the dispersion to a crucible, place it in a microwave oven for 15 minutes; wash the microwaved product repeatedly with water and suction filtration to remove potassium hydroxide until the filtrate is neutral and dried to obtain a solid; weigh 5 g of the above solid, mix with 15 g of potassium chlorate and 250 g of water, react in a reactor for 2 hours, and set the reaction temperature to 150 ° C; after the reaction The product is taken out, repeatedly washed with water and suction filtered to remove excess potassium chlorate, and dried to obtain a micro-graphene oxide product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com