An anti-shock electromagnetic unloading valve for a straight-arm truck-mounted crane

A truck-mounted crane and anti-shock technology, which is applied to cranes, mechanical equipment, fluid pressure actuators, etc., can solve the problems of large size, small flow capacity, and large reversing impact, and achieve good sealing performance and communication The effect of large flow capacity and downscaling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with accompanying drawing.

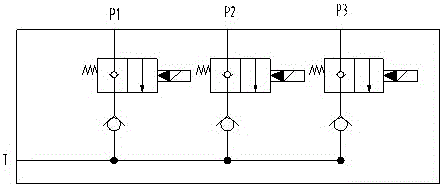

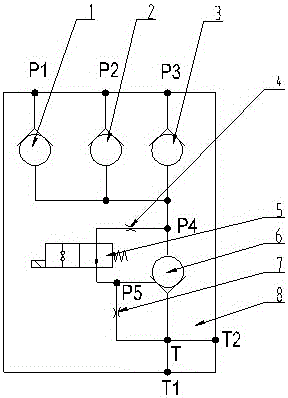

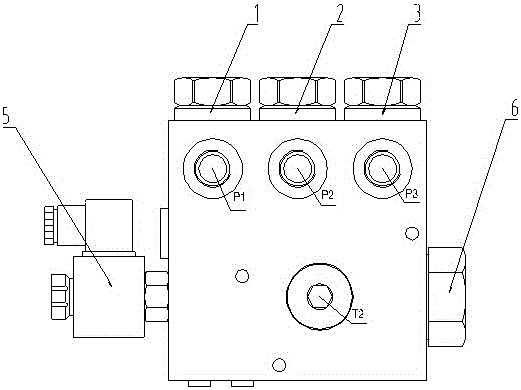

[0015] Such as Figure 2 to Figure 4 As shown, the anti-shock electromagnetic unloading valve of the straight arm truck-mounted crane includes a valve body 8, a first one-way valve 1, a second one-way valve 2, a third one-way valve 3 and an electromagnetic reversing valve 5, The surface of the valve body 8 is provided with the first oil port P1, the second oil port P2, the third oil port P3, the first oil return port T1 and the second oil return port T2, and the valve body 8 is provided with the front oil port P4, The control oil port P5 and the oil port T behind the valve; the first check valve 1, the second check valve 2, and the third check valve 3 respectively communicate with the first oil port P1, the second oil port P2, and the third oil port in one direction. The oil passage from port P3 to the pre-valve port P4, the check valve group composed of the first check va...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com