Loader with bimotored power system

A power system and dual-engine technology, applied in the direction of power plant, transportation and packaging, jet propulsion device, etc., can solve the problems of high fuel consumption rate, difficult to achieve global power optimization and local optimization of engine and load, so as to alleviate the impact, Ease of stepless speed change and the effect of increasing the load rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

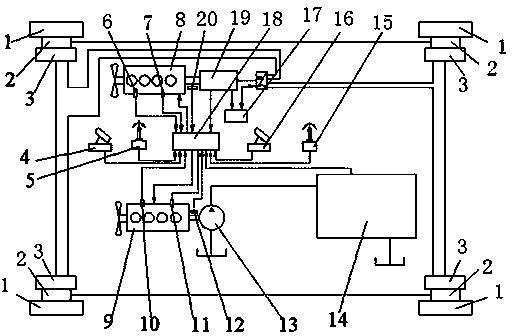

[0016] The present invention will be further described below in conjunction with the accompanying drawings:

[0017] figure 1 As shown, the power drive route of the dual-engine power system loader is divided into two parts: first, the first engine 8, the generator 19, the power storage device 17, the motor / generator 3, the driving wheel 1, the brake pedal 4. The forward / reverse gear lever 5, the travel speed control pedal 16, and the control unit 18 constitute the drive system of the loader traveling device.

[0018] Second, the second engine 9 , the hydraulic pump 13 , the hydraulic device 14 , the throttle control switch 15 of the second engine 9 , and the control unit 18 constitute the drive system of the loader working device.

[0019] In the driving system of the loader traveling gear, the rotational speed of the first engine 8, the coolant temperature and the oil temperature are fed back to the control unit 18 through the first rotational speed sensor 20, the first cool...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com