Humidification stirring system

A stirring system and stirring blade technology, which are applied in mixers with rotating stirring devices, dissolving, packaging, etc., can solve the problems of weak conveying and stirring function of spiral blades, easy wear of casings and blades, and complex structure, etc., and reach the scope of application. Wide, prevent wet material agglomeration, compact and simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

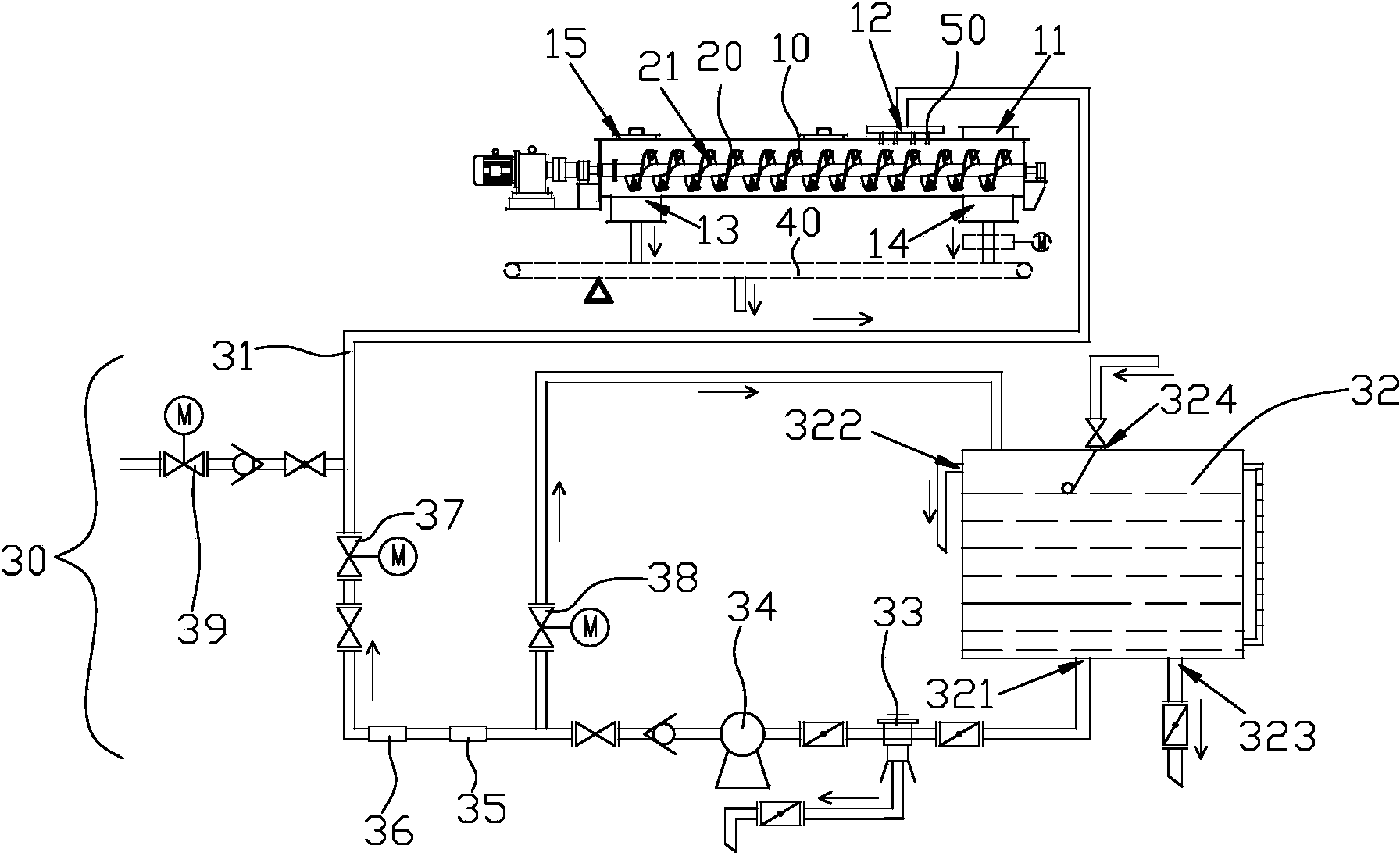

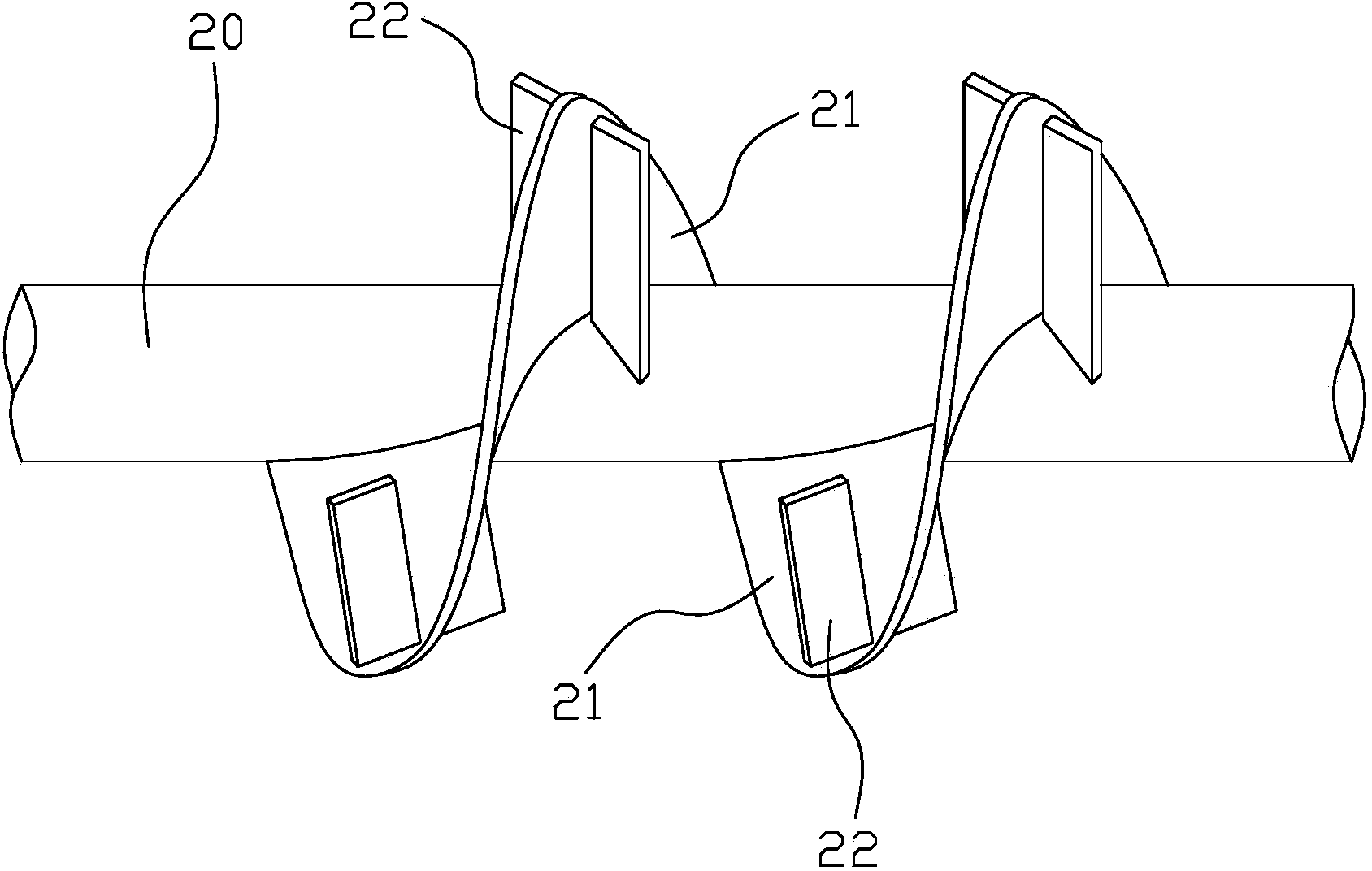

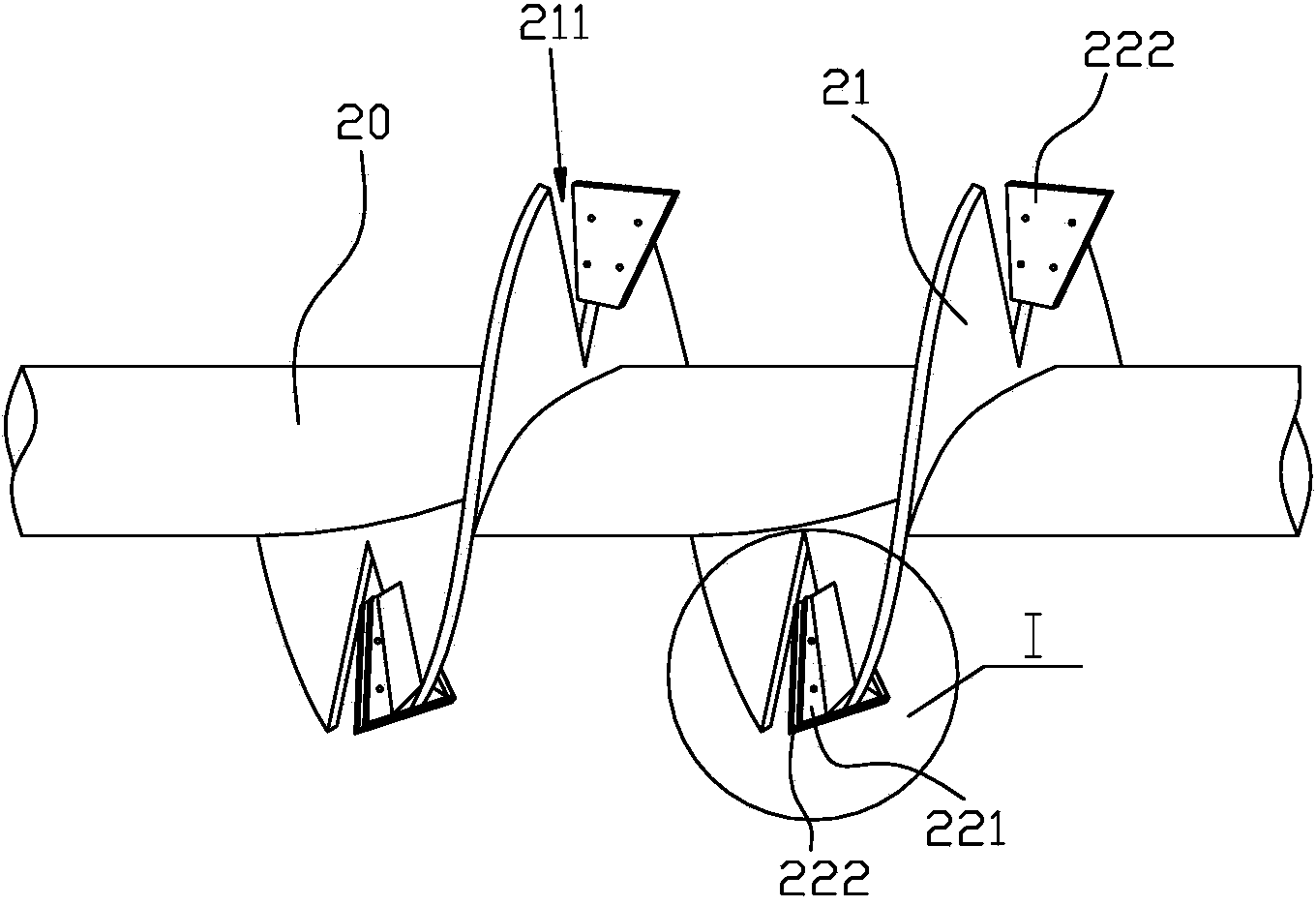

[0009] A humidification mixing system, such as Figure 1-4 As shown, it includes a box body 10 and a rotating shaft 20 arranged on the box body 10. The upper part of one end of the box body 10 is provided with a solid particle material inlet 11 and a water spray port 12, and the lower part of the other end of the box body 10 is provided with a solid particle material. The wet material outlet 13 after the material and water are mixed, the water spray port 12 is connected with the water pipe 31 of the water spray device 30, and the shaft body 20 in the box body 10 is fixedly provided with a helical blade 21, and the helical blade 21 Stirring blades 22 are arranged on at least one side of the blade surface, and the blade surfaces of the stirring blades 22 and the blade surfaces of the spiral blades 21 at their positions are arranged at an angle. The helical blade 21 and the stirring blade 22 have the functions of pushing the material forward and cleaning the wet material at the b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com