Anhydrous dextrose drying device and drying process

A technology of anhydrous glucose and drying equipment, applied in the field of biomedicine, can solve the problems of low output per unit area, poor boiling effect, energy waste, etc., achieve significant economic and environmental benefits, ensure the boiling effect, and achieve continuity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

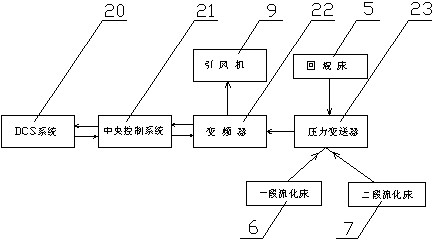

[0050] according to figure 1 and figure 2 As shown, the anhydrous glucose drying equipment includes a fluidized bed and a back-mixed bed, and the fluidized bed includes a first-stage fluidized bed 6 and a second-stage fluidized bed 7, and the outlet of the first-stage fluidized bed 6 is connected to the second-stage fluidized bed The feed port of the section fluidized bed 7 is connected, the back mixed bed 5 and the first section fluidized bed 6 are connected by pipelines, the back mixed bed 5, the first section fluidized bed 6 and the second section fluidized bed 7 are respectively connected with the cyclone separator 8 and the introduction The blower 9 is connected through pipelines, and the lower part of the mixed bed 5 is connected with the air inlet pipe I3 through the air blower I1. There is a heat exchanger I2 on the air inlet pipe I3. Inlet pipe Ⅴ17 is respectively connected to the second-stage fluidized bed 7, blower Ⅱ11 is respectively connected to air inlet pipe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com