IML reverse covering process of laundry machine panel

A technology of reverse edging and washing machine, which is applied to flat products, household appliances, other household appliances, etc., can solve the problems of easy scratches on the surface of the sheet in the rubber sealing area of the slider, large injection pressure loss, and long production cycle. The appearance of the product is easy to guarantee, the injection pressure loss is small, and the development cost is reduced.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The specific implementation manners of the present invention will be further described below in conjunction with the accompanying drawings and embodiments. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

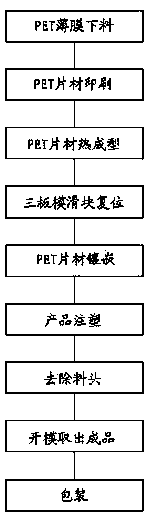

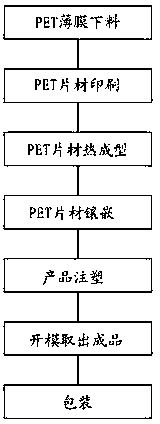

[0036] Such as figure 2 Shown, a kind of washing machine panel IML reverse wrapping process, a kind of washing machine panel IML reverse wrapping process may further comprise the steps:

[0037] S1: PET film blanking, cut the PET film into PET sheets of corresponding size according to the shape of the product;

[0038] S2: PET sheet printing, printing pattern on PET sheet by screen printing machine;

[0039] S3: Thermoforming of PET sheet, thermoforming the printed PET sheet by thermoforming machine;

[0040] S4: PET sheet inlay, positioning the printed side of the thermoformed PET sheet downward and putting it into t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com