Cooling water channel structure of automobile engine cooling fan mold

A technology for an automobile engine and a cooling water circuit, which is applied in the field of cooling water circuit structure, can solve problems such as the adverse effect of injection molding production efficiency, the insignificant cooling effect of fan blades, and the inability of the curved surface shape of fan blades to reach the desired ideal shape, etc., so as to improve performance. , good cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described in detail below with reference to the embodiments of the accompanying drawings.

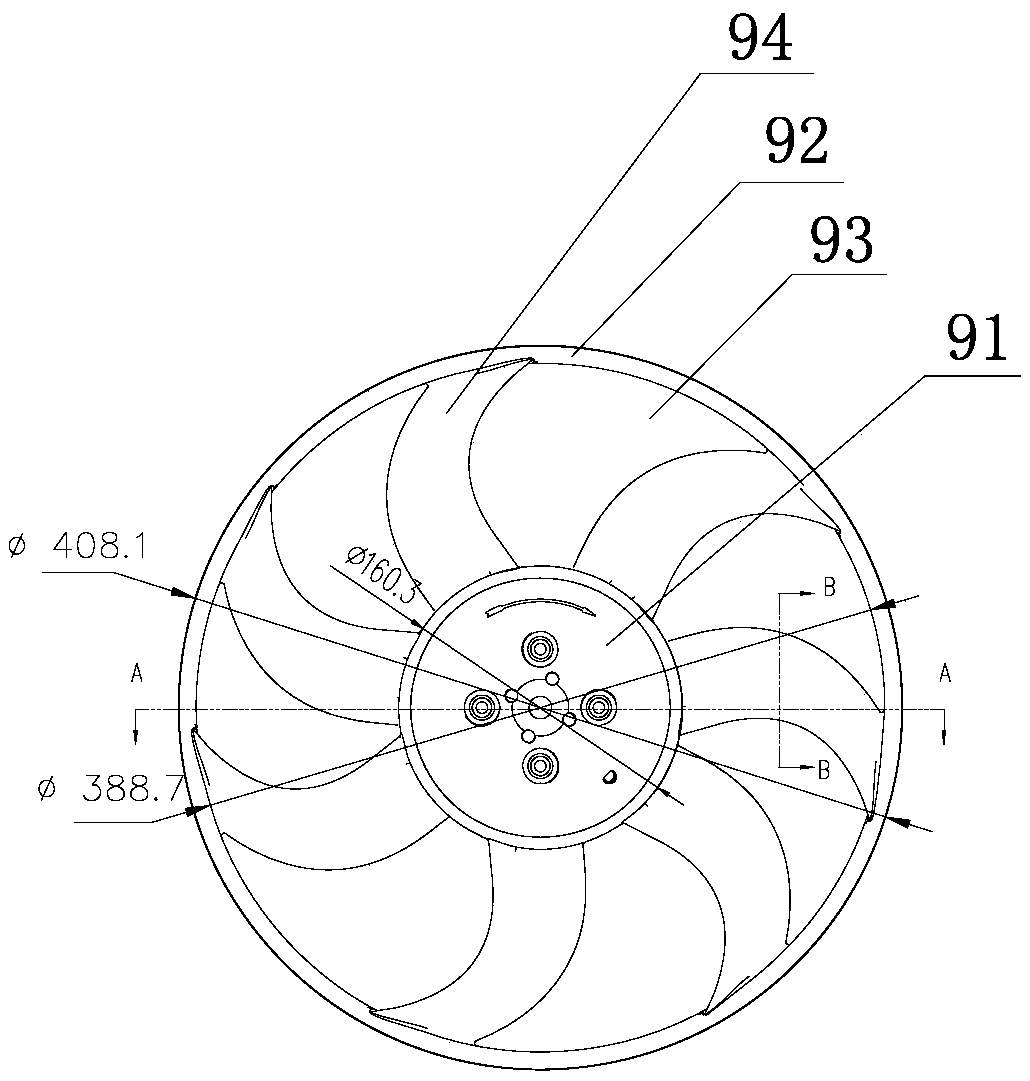

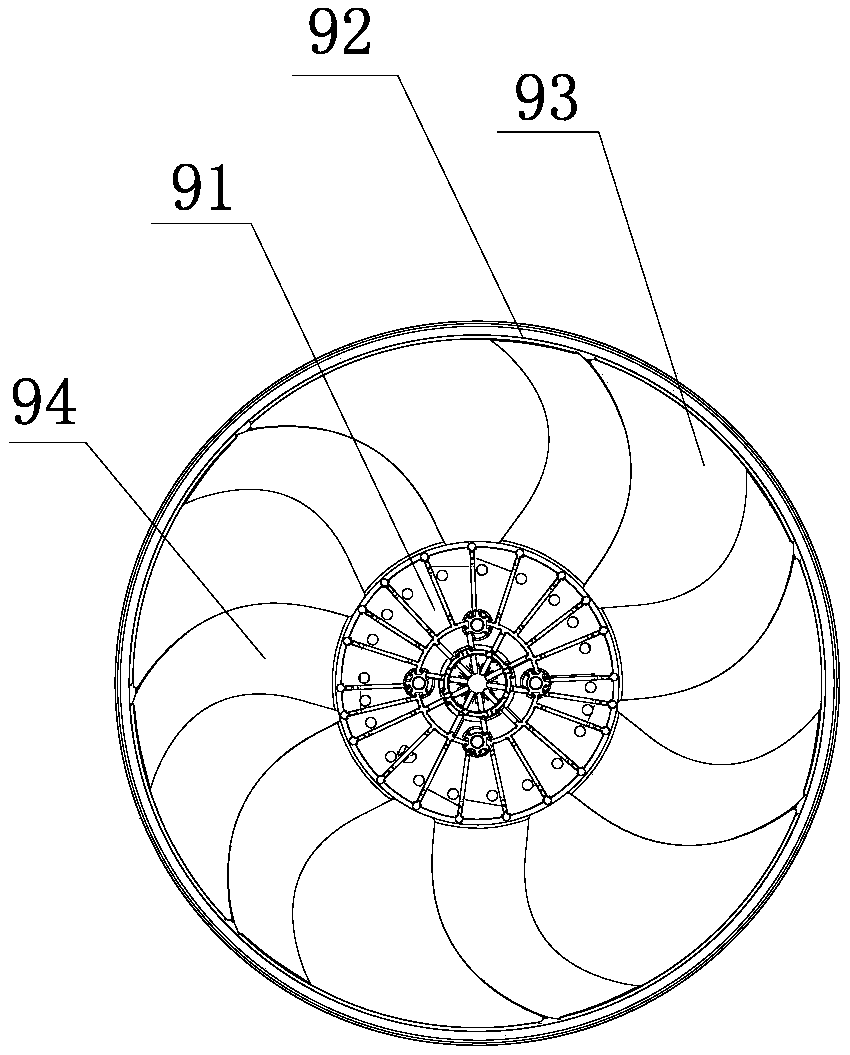

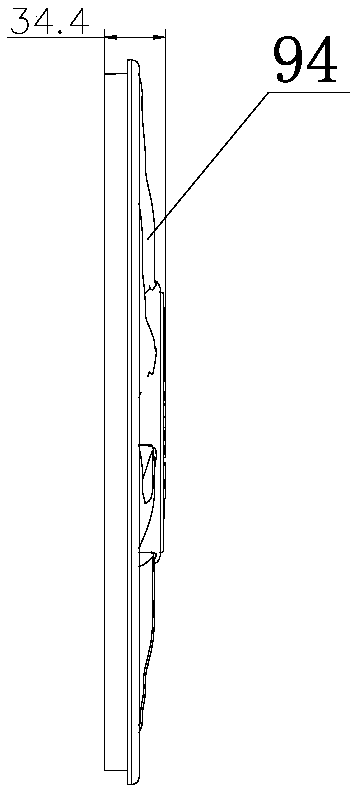

[0036] The cooling water channel structure in a kind of automobile engine cooling fan mold that the present invention proposes, such as Figure 2 to Figure 9 As shown, it is composed of the fixed mold side waterway 1 arranged on the back side of the fixed mold side fan cavity 81 and the movable mold side waterway 2 arranged on the back side of the movable mold side fan cavity 82; the fixed mold side waterway 1 includes 7 The fixed mold side water well type waterway 11 that works independently, the number of the fixed mold side water well type waterway 11 is the same as the number of blade cavities 811 in the fixed mold side fan cavity 81, and each fixed mold side water well type waterway 11 is arranged on the fixed mold side On the back side of a blade cavity 811 in the side fan cavity 81, each fixed mold side water well type waterway 11 has ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com