A large disc tooth surface cutting and processing equipment

A cutting and disc technology, used in metal processing equipment, welding/cutting auxiliary equipment, welding equipment, etc., can solve the problems of large torque, low work efficiency, high efficiency power, etc., and achieve the effect of improving manufacturing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

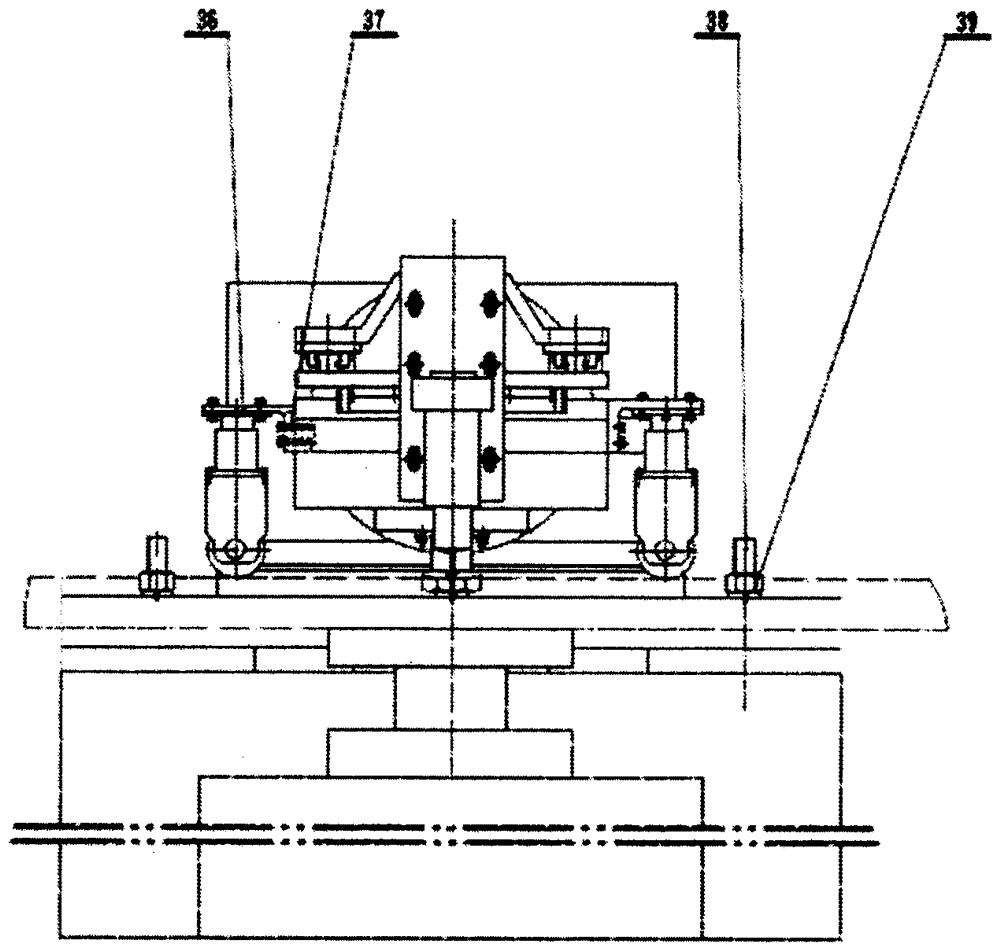

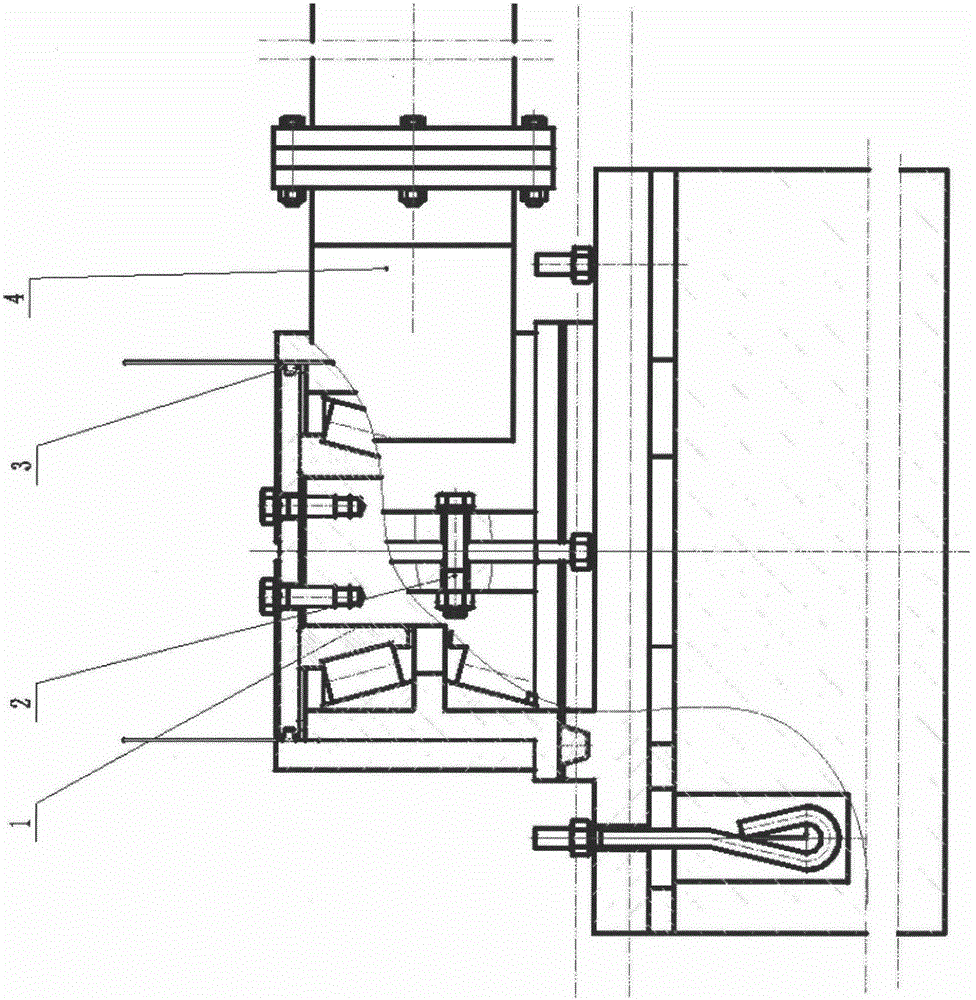

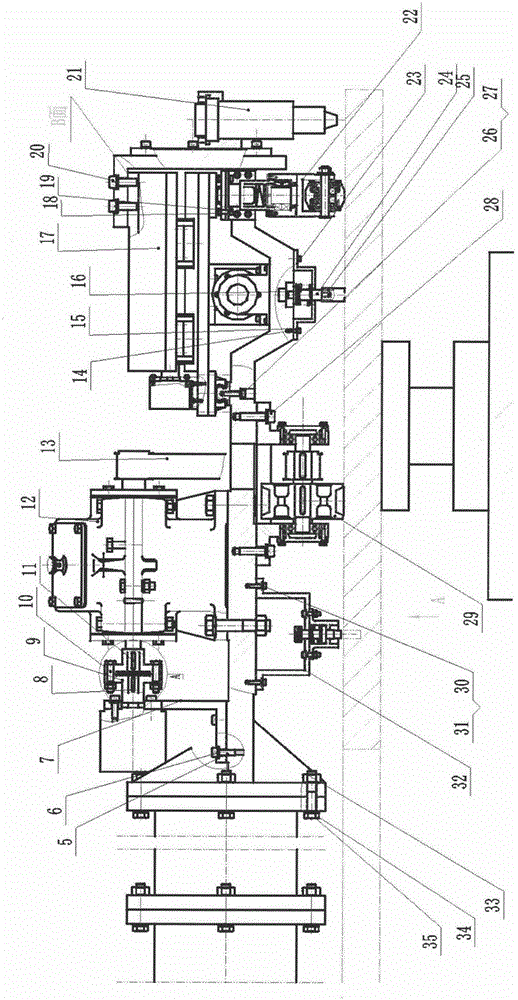

[0021] Before further describing the technical solutions described in the embodiments of the present invention, it is necessary to describe the overall design idea of the embodiments of the present invention. It should be understood that the embodiment of the present invention is mainly designed on the background of gear processing, and any design ideas following the technical solution of the embodiment of the present invention shall fall within the scope of protection of this application document. The overall design idea of the embodiment of the present invention mainly includes the following contents:

[0022] 1) Positioning: In order to ensure that the rotating arm and the workpiece do not rotate relative to each other during processing, a mechanical limit device must be installed between the rotating arm and the workpiece, and the indexing must be accurately indexed and positioned. Considering that the rotating arm is heavy and it is difficult to push the rotating arm ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com