Apparatus and method for removing damaged areas of fiber-reinforced composite materials

A composite material, fiber-reinforced technology, applied in welding equipment, laser welding equipment, metal processing equipment and other directions, can solve the problems of unstable processing quality, difficult layer processing, new micro-cracks, etc., to improve the degree of equipment automation, The effect of fast speed and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The preferred embodiments of the present invention are described in detail below, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, so as to define the protection scope of the present invention more clearly.

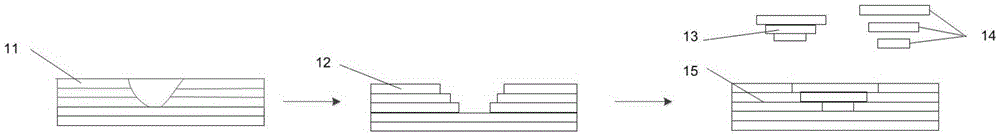

[0034] A method and device for removing a damaged region of a composite material, that is, using an infrared pulse laser to remove the damaged region of the composite material layer by layer, and finally realizing the layered removal of the composite material.

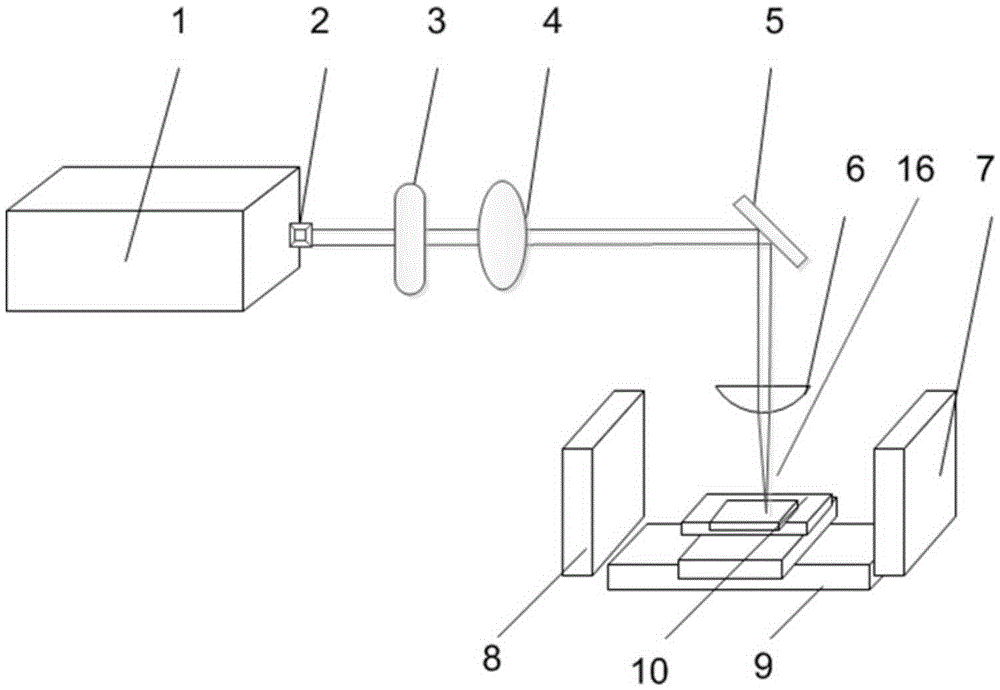

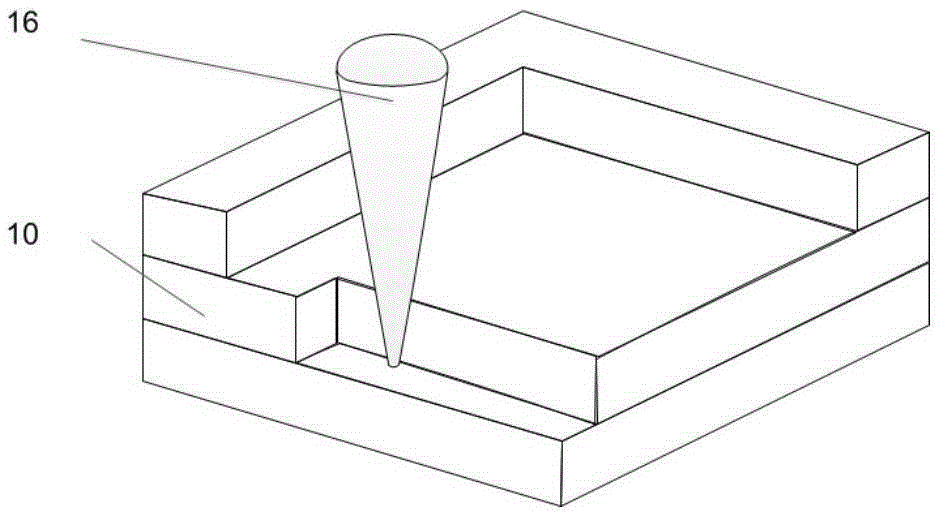

[0035] like figure 1 As shown, it is a device diagram of the infrared nanosecond laser used in the present invention to remove the damaged area of the fiber reinforced composite material layer by layer. The coaxial light source 2 makes the laser optical axis and the red indicator light source on the same axis, ensuring that The optical path has the guiding function of visible light. The laser light emitted by the laser 1 passes throug...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com