Preparation method of pucherite/graphene compound photo-catalyst with controllable particle size

A graphene composite and photocatalyst technology, applied in physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, chemical instruments and methods, etc., can solve the problem of low efficiency of photogenerated electron-hole separation , to achieve the effect of excellent catalytic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] The first step, the specific steps for preparing graphite oxide are as follows: the graphite oxide is prepared in the following manner: under ice-water bath conditions, add 1g NaNO to 40mL of sulfuric acid solution with a concentration of 98wt%. 3 and 2g flake graphite, stir for 30min; add 3g potassium permanganate to the above mixed solution, control the temperature at 10°C, stir for 1h; raise the temperature to 35°C, keep for 1h; add 60ml of deionized water dropwise and slowly heat up to 100°C, Add 5% hydrogen peroxide solution dropwise and stir for 1 h; wash with 5% HCl solution several times; after centrifugal filtration, vacuum dry at 60° C. for 48 h to obtain the desired graphite oxide.

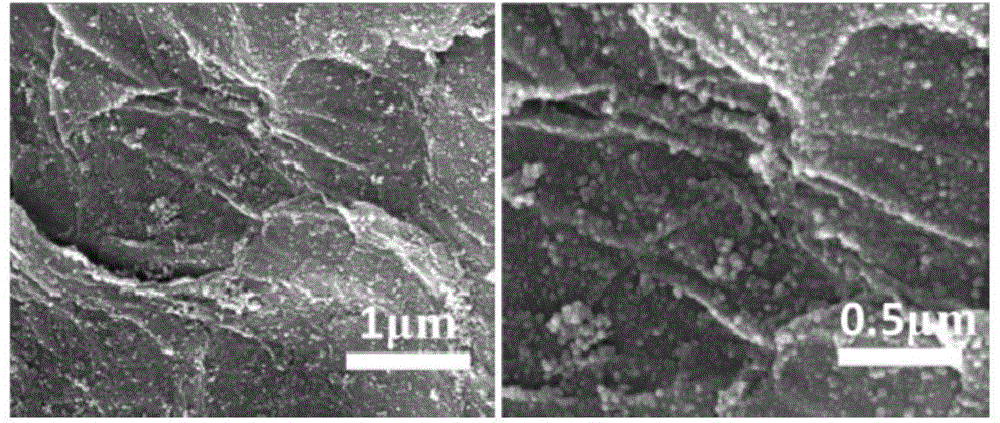

[0025] In the second step, the preparation process of the precursor solution of the bismuth vanadate nanoparticles / graphene composite is as follows: (1) a certain amount of Bi(NO 3 ) 3 ·5H 2 O powder, add to 140mL mixed solution of alcohol and glycerin, stir and mix well at 60-80...

Embodiment 2

[0032] The first step, the specific steps for preparing graphite oxide are as follows: the graphite oxide is prepared in the following manner: under ice-water bath conditions, add 1g NaNO to 40mL of sulfuric acid solution with a concentration of 98wt.%. 3 and 2g flake graphite, stir for 30min; add 3g potassium permanganate to the above mixed solution, control the temperature at 10°C, stir for 1h; raise the temperature to 35°C, keep for 1h; add 60ml of deionized water dropwise and slowly heat up to 100°C, Add 5% hydrogen peroxide solution dropwise, stir for 1 h; wash with 5% HCL solution several times; after centrifugal filtration, vacuum dry at 60° C. for 48 h to obtain the desired graphite oxide.

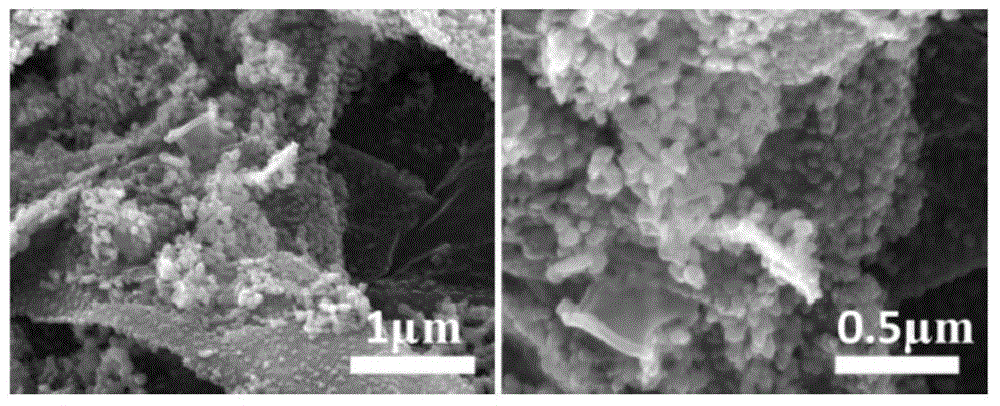

[0033] In the second step, the precursor solution configuration process of the bismuth vanadate nanoparticles / graphene composite is as follows: (1). A certain amount of Bi(NO 3 ) 3 ·5H 2 O powder, added to 140mL mixed solution of alcohol and glycerin, stirred and mixed evenly at ...

Embodiment 3

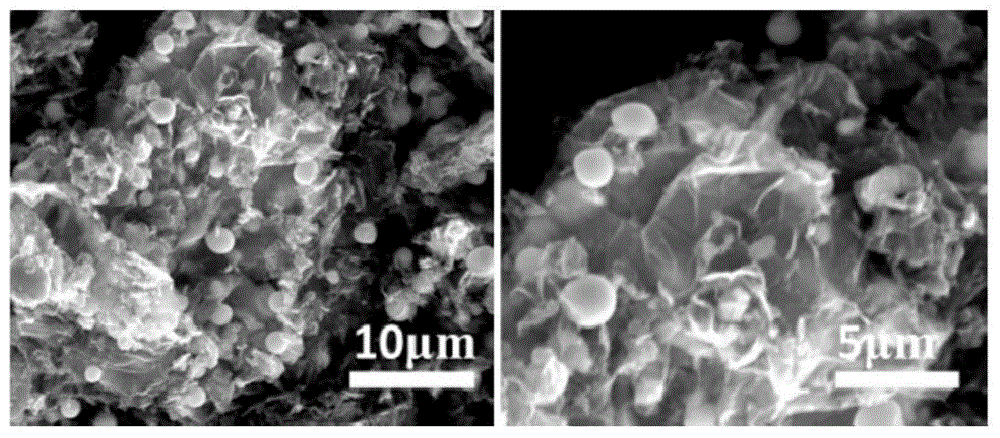

[0039] The first step, the specific steps of preparing graphite oxide are as follows: the graphite oxide is prepared in the following way: under ice-water bath conditions, add 1g NaNO to 40ml of sulfuric acid solution with a concentration of 98wt.%. 3 and 2g flake graphite, stir for 30min; add 3g potassium permanganate to the above mixed solution, control the temperature at 10°C, stir for 1h; raise the temperature to 35°C, keep for 1h; add 60mL of deionized water dropwise and slowly raise the temperature to 100°C, Add 5% hydrogen peroxide solution dropwise, stir for 1 h; wash with 5% HCL solution several times; after centrifugal filtration, vacuum dry at 60° C. for 48 h to obtain the desired graphite oxide.

[0040] In the second step, the precursor solution configuration process of the bismuth vanadate nanoparticles / graphene composite is as follows: (1). A certain amount of Bi(NO 3 ) 3 ·5H 2 O powder, added to 140mL mixed solution of alcohol and glycerin, stirred and mixed ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com