Urea solution tank filling assembly used for SCR system

A technology of SCR system and solution tank, which is applied in the field of SCR system, can solve the problems of tank body expansion, cumbersome assembly, easy to wrap the tank cover, etc., and achieve the effect of stable and reliable use and convenient assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

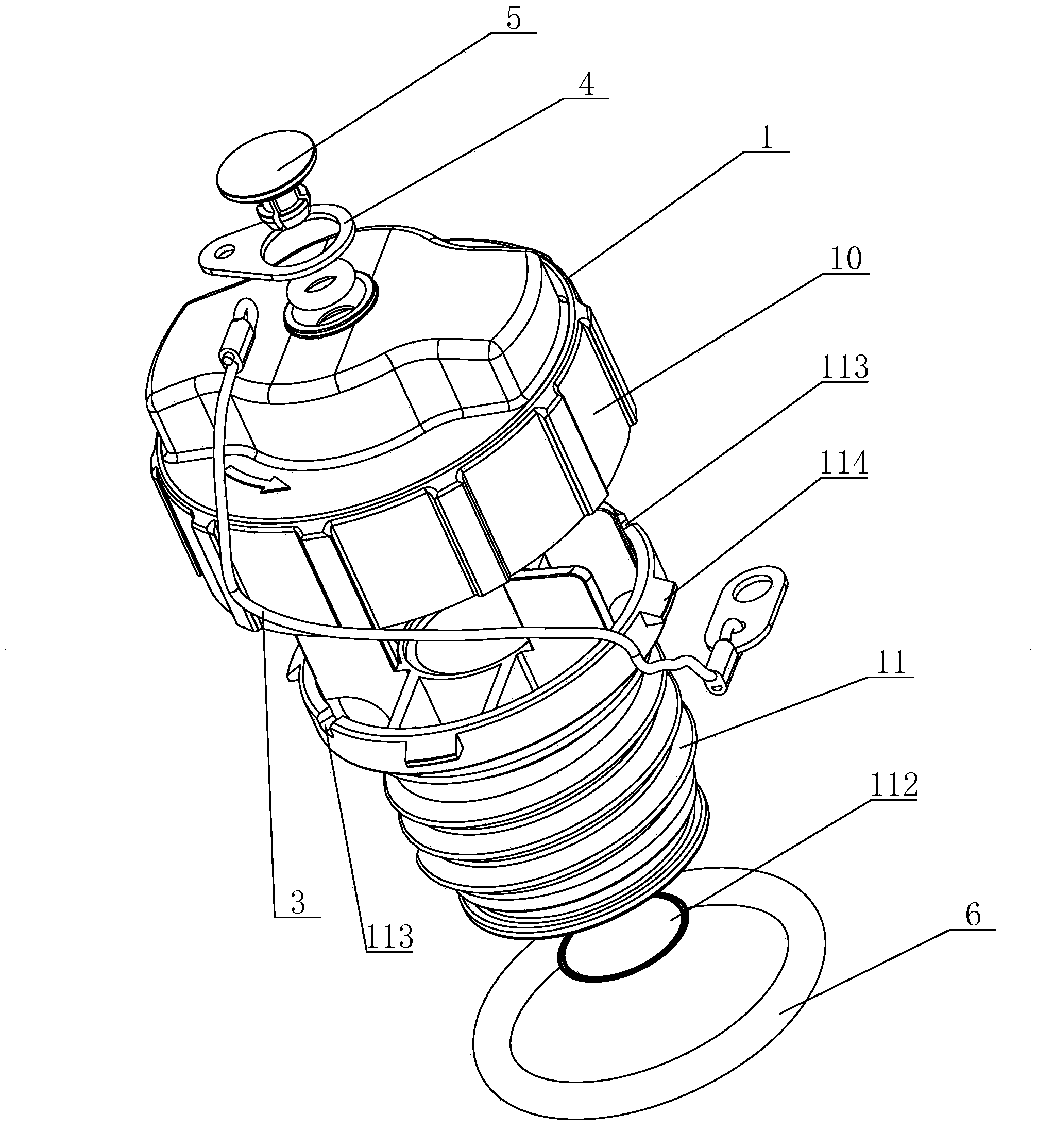

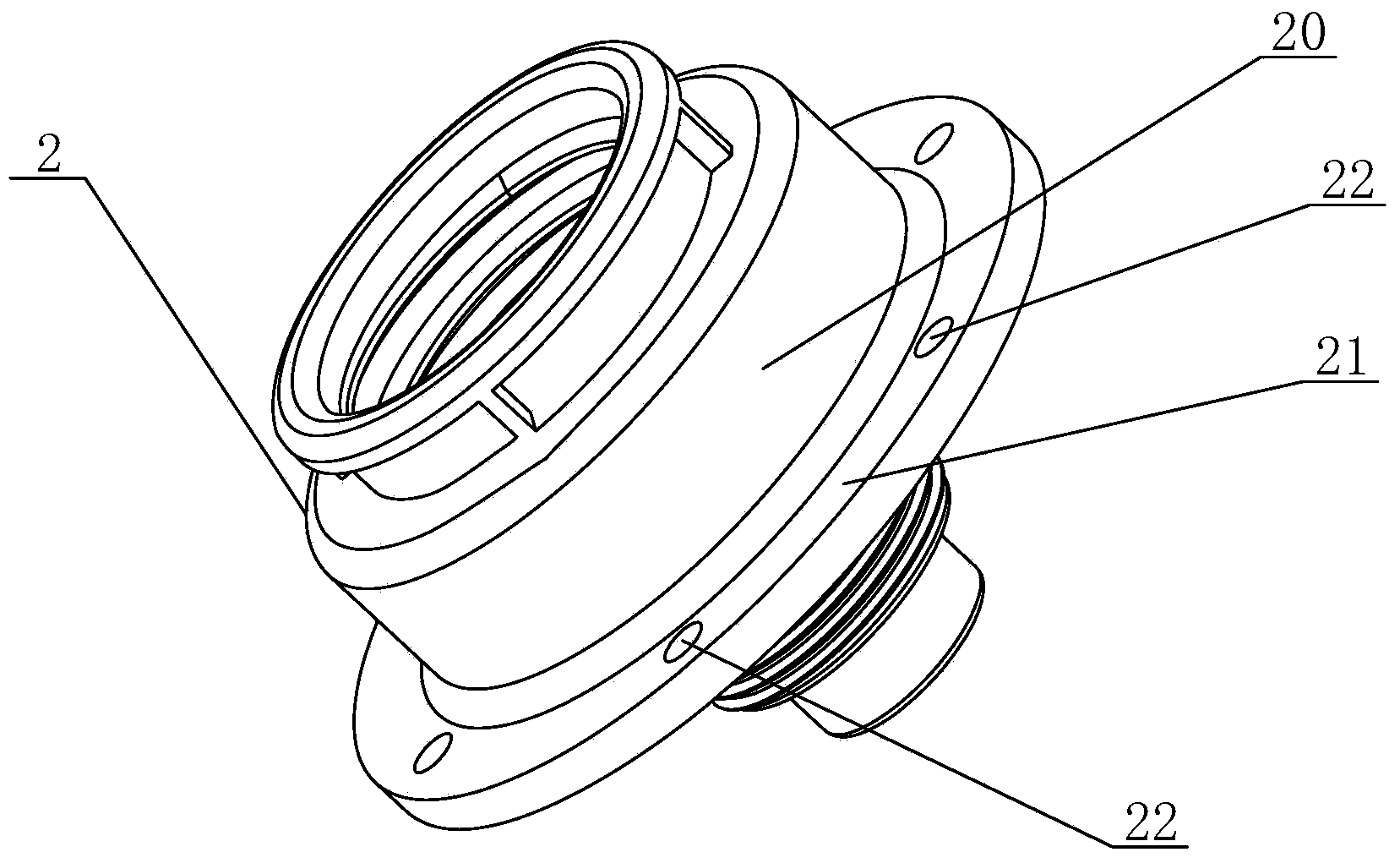

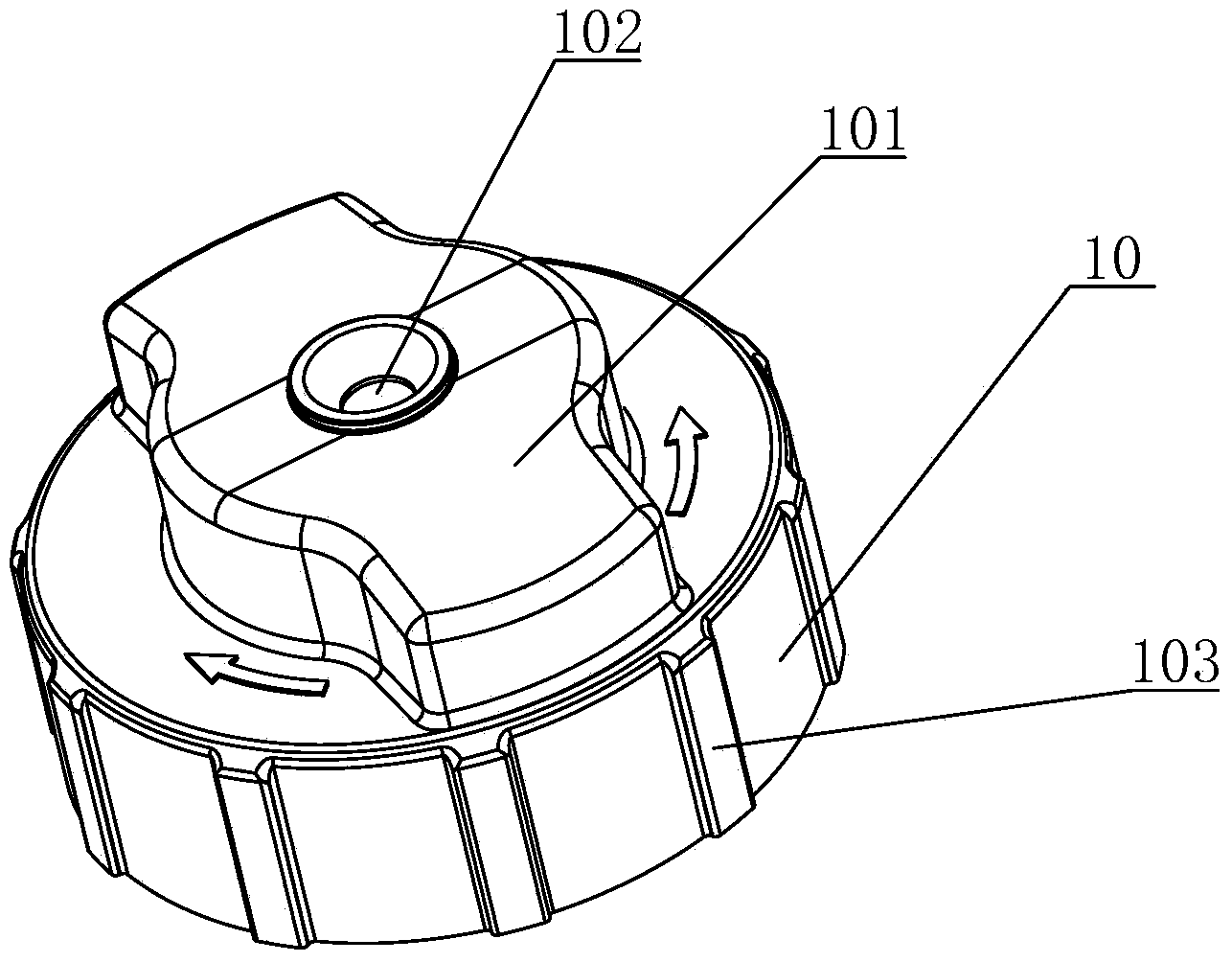

[0033] see Figure 1 to Figure 6 As shown, in this embodiment, a urea solution tank filling assembly for an SCR system includes a tank cover 1 and a filling port 2, and the tank cover 1 includes an upper outer cover 10 and a lower outer cover 11. The center of the lower outer cover 11 is provided with a vent chamber 110, and the bottom of the vent chamber 110 is provided with several vent holes 111, and the vent chamber 110 is provided with a vent membrane 112 above the vent holes 111, and the vent chamber 110 The top of the lower outer cover 11 is provided with several ventilation slots 113 and connected to the upper outer cover 10, the bottom of which is connected to the filling port 2, and the top of the lower outer cover 11 extends outwards with several chucks 114 , a plurality of slots are arranged on the top of the upper outer cover 10 in conjunction with the chuck 114 , and the chuck 114 is stuck in the slots to connect the lower outer cover 11 to the upper outer cover ...

Embodiment 2

[0037] see Figure 7 and Figure 8 As shown, the difference between this embodiment and Embodiment 1 is that an anti-loosening device is provided between the tank cover 1 and the filling port 2 , and the anti-loosening device includes an upper part of the filling port body 20 The anti-loosening teeth 23, cooperate with the anti-loosening teeth 23 to open a long anti-loosening bayonet 104 on the corresponding position of the upper outer cover 10, and the upper outer cover 10 is on the bottom of the anti-loosening bayonet 104 There is a raised part 105 extending downwards. When locking, the anti-loosening teeth 23 are stuck in the anti-loosening bayonet 104 to prevent the tank cover 1 from loosening. When opening the cover, rotate the upper outer cover 10, and the upper outer cover 10 will The protruding portion 105 on the cover 10 is deformed under force, so that the anti-loosening tooth 23 is separated from the anti-loosening bayonet 104 to realize unlocking.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com