Hollow layering steam injecting system

A technology of layered steam injection and steam injection, which is applied in the fields of production fluids, wellbore/well components, earth-moving drilling, etc., and can solve the problems of steam leakage, easy steam leakage, affecting the accuracy of steam injection, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described with reference to the accompanying drawings.

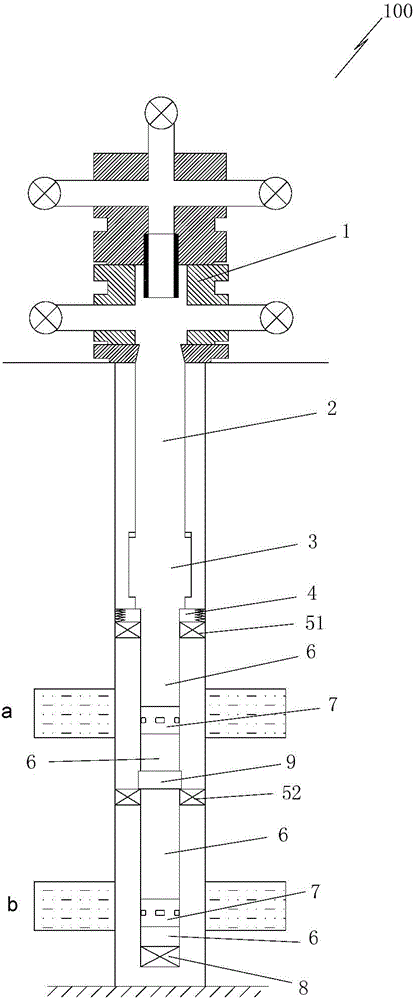

[0021] Such as figure 1 As shown, the present invention provides a hollow layered steam injection system 100, which is used to perform layered steam injection on two or more oil layers. In this embodiment, the case of two oil layers is used as an example for illustration . The steam injection system 100 includes a wellhead device 1. The wellhead device 1 uses snubbing steam to drive the wellhead. The wellhead is a prior art. The wellhead has a simple structure, and the transportation distance of steam in the wellhead is short, reducing the chance of steam leakage. The insulation oil pipe 2 is threadedly connected under the wellhead device. The insulation oil pipe adopts BG80H insulation oil pipe. Heat loss during transportation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com