Organic porous polymer based on triptycene skeleton as well as preparation method and application of organic porous polymer

A porous polymer and organic technology, applied in the direction of educts, other chemical processes, chemical instruments and methods, etc., can solve the problems that the performance of organic porous materials needs to be further improved

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0124] Preparation of organic porous polymers

[0125] The present invention also provides a method for preparing the organic porous polymer, the organic porous polymer is prepared by the following method:

[0126] (1) In an inert solvent, carry out dehydration condensation with a compound of formula II and a compound of formula I to obtain an organic porous polymer as described in the present invention;

[0127] Wherein, described formula II compound and formula I compound are as follows:

[0128]

[0129] Wherein, the definition of each group is as described above, n≥2, preferably n>2.

[0130] In a preferred embodiment of the present invention, the organic porous polymer is prepared by the following method:

[0131] (1a) in an inert solvent, carry out dehydration condensation with the compound of formula IIa and the compound of formula I, obtain the organic porous polymer as described in the present invention;

[0132] Or described organic porous polymer is prepared b...

Embodiment 1

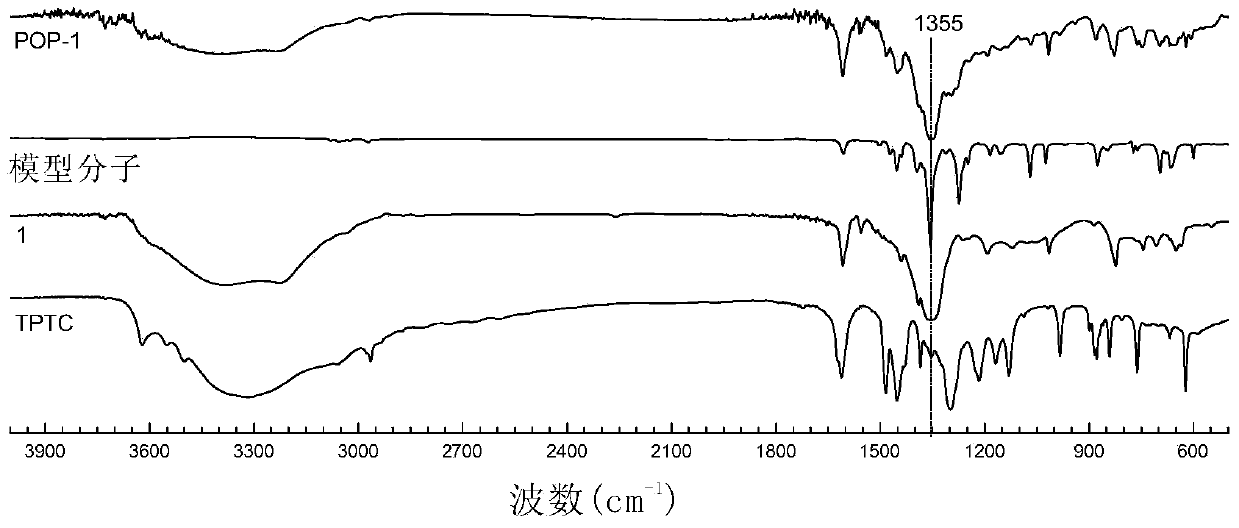

[0163] The preparation of embodiment 1POP-1

[0164] Redistill dioxane and mesitylene, weigh 30 mg hexahydroxytriptycene and 52 mg 1,3,5-tris(4-phenylboronic acid) benzene, add them into a sealed tube, add 3 milliliters of dioxane and 3 mL of mesitylene, and place the sealed tube in liquid nitrogen to cool for 10 min. Use an oil pump to pump air for 10 minutes. Thaw in ethanol after closing the gas valve. Place in an oven and keep at 85°C for 5 days. After the reaction is finished, wash with acetone and filter with suction, and then use an oil pump to dry at 120°C. The obtained white powder is the polymer of the present invention, and the yield is 85%.

Embodiment 2

[0165] The preparation of embodiment 2POP-1

[0166] Redistill dioxane and mesitylene, weigh 30 mg hexahydroxytriptycene and 52 mg 1,3,5-tris(4-phenylboronic acid) benzene, add them to a sealed tube, add 2 ml dioxane and 3 mL of mesitylene, and place the sealed tube in liquid nitrogen to cool for 10 min. Use an oil pump to pump under reduced pressure for 10 minutes. Thaw in ethanol after closing the gas valve. Place in an oven and keep at 85°C for 5 days. After the reaction is finished, wash with acetone and filter with suction, and then use an oil pump to dry at 120°C. The obtained white powder is the polymer of the present invention, and the yield is 80%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com