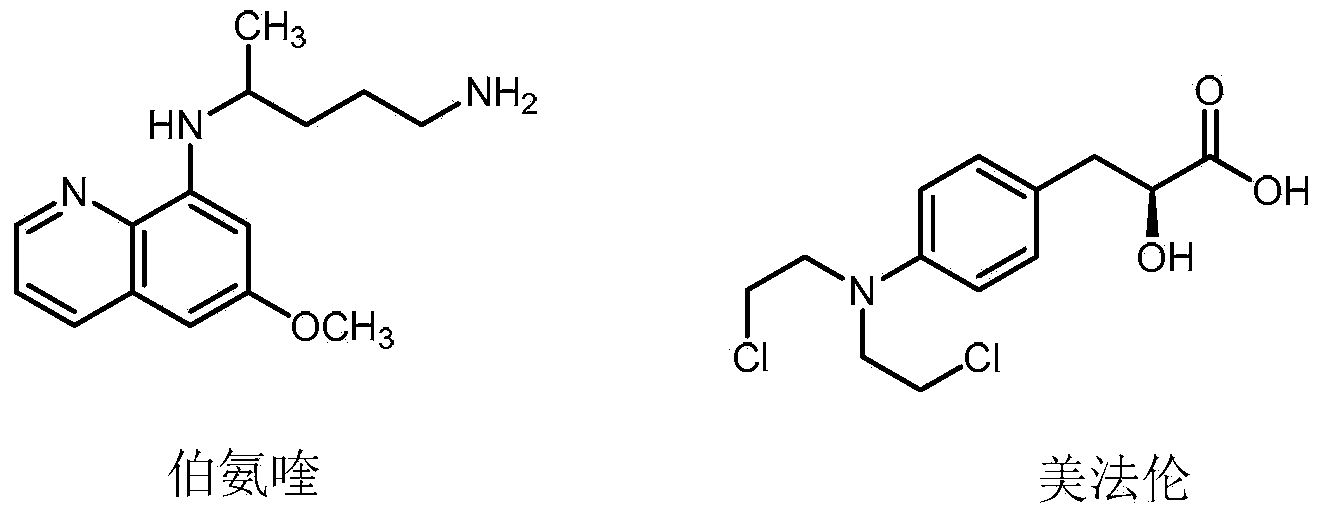

Method for preparing alkylaryl amine compound through microwave synthesis

A technology of alkylaryl and microwave synthesis, which is applied in the chemical industry, can solve the problems of harsh reaction conditions and high environmental costs, and achieve the effects of short reaction time, convenient post-processing, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

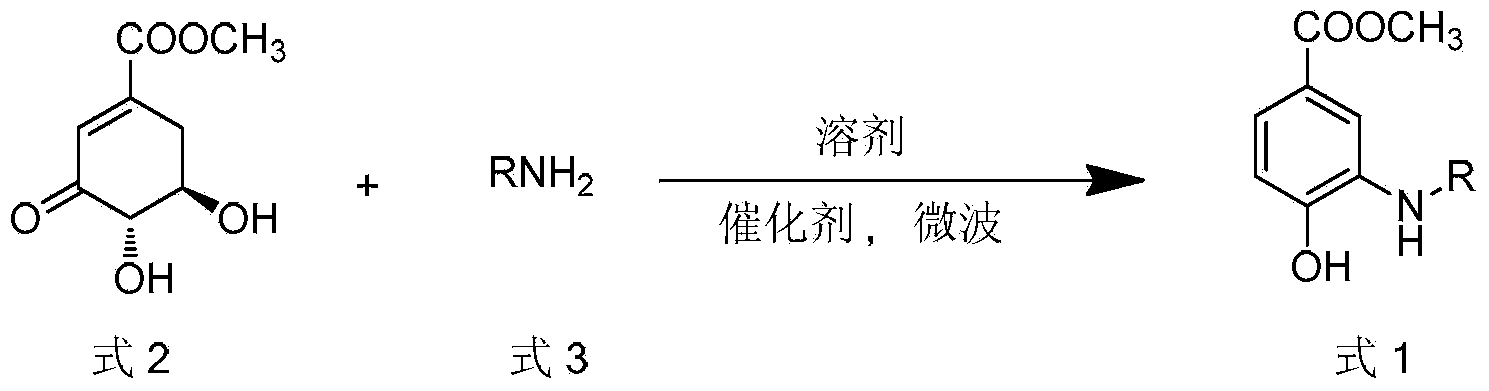

Method used

Image

Examples

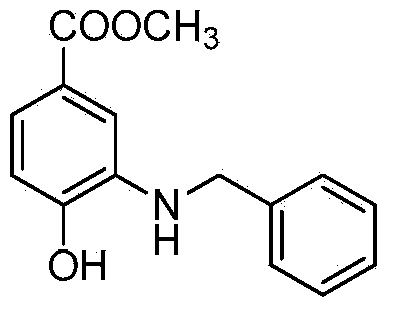

Embodiment 1

[0022] The preparation of 3-benzylamino-4-hydroxybenzoic acid methyl ester comprises the following steps:

[0023] Add methyl 3-dehydroshikimate (0.37g, 2.0mmol), benzylamine (0.19g, 1.8mmol), p-toluenesulfonic acid (18mg, 0.1mmol), and 5ml dimethyl sulfoxide into the microwave reaction flask at one time middle. The reaction system was reacted at 130° C. for 10 min in a microwave reactor. The reaction was monitored by TLC. After the reaction was completed, after cooling, the reaction solution was poured into 80ml of saturated saline solution, stirred continuously, and a solid was precipitated, filtered by suction, and the solid was recrystallized with dichloromethane-petroleum ether to obtain white crystals of 3-benzylamino-4- Methyl hydroxybenzoate 0.38g, yield: 82%.

[0024] The characterization data of the product is: m.p.147-149°C; 1 H NMR (400MHz, DMSO-d 6 )δ:ppm10.30(s,1H),7.28-7.34(m,4H),7.18-7.22(m,1H),7.10-7.13(dd,J 1 =8.00Hz,J 2 =2.00Hz,1H),6.93(d,J=1.60Hz,1H),...

Embodiment 2

[0027] The preparation of 3-cyclohexylamino-4-hydroxybenzoic acid methyl ester comprises the following steps:

[0028] Methyl 3-dehydroshikimate (0.37g, 2.0mmol), cyclohexylamine (0.22g, 2.2mmol), p-toluenesulfonic acid (36mg, 0.2mmol), 5ml N,N-dimethylformamide once added to a microwave reaction vial. The reaction system was reacted at 120° C. for 15 min in a microwave reactor. The reaction was monitored by TLC. After the reaction was completed, after cooling, the reaction solution was poured into 30ml saturated brine, extracted with ethyl acetate (3×30ml), the extract was washed with water, dried, and the solvent was removed by rotary evaporation. Hexylamino-4-hydroxybenzoic acid methyl ester 0.35g, yield: 70%.

[0029] The characterization data of the product is: m.p.152-154°C; 1 H NMR (400MHz, DMSO-d 6 )δ:ppm10.25(s,1H),7.11(dd,J 1 =8.00Hz,J 2 =2.00Hz,1H),7.03(d,J=2.00Hz,1H),6.72(d,J=8.00Hz,1H),4.39(s,1H),3.74(s,3H),3.21(m,1H ),1.90-1.93(m,2H),1.67-1.70(m,2H),1.57-1...

Embodiment 3

[0032] The preparation of 3-butylamino-4-hydroxybenzoic acid methyl ester comprises the following steps:

[0033] Methyl 3-dehydroshikimate (0.37g, 2.0mmol), n-butylamine (0.15g, 2.0mmol), p-toluenesulfonic acid (3.6mg, 0.02mmol), 5ml N,N-dimethylmethylamine Add to the microwave reaction vial at one time. The reaction system was reacted at 160° C. for 8 min in a microwave reactor. The reaction was monitored by TLC. After the reaction was completed, after cooling, the reaction solution was poured into 30ml of saturated brine, extracted with ethyl acetate (3×30ml), the extract was washed with water, dried, and the solvent was removed by rotary evaporation. Column chromatography gave white crystals of 3-butyl Amino-4-hydroxybenzoic acid methyl ester 0.30g, yield: 68%.

[0034] The characterization data of the product is: m.p.107-109°C; 1 H NMR (400MHz, DMSO-d 6 )δ:ppm10.25(s,1H),7.12(dd,J 1 =8.00Hz,J 2 =2.00Hz,1H),7.00(d,J=2.00Hz,1H),6.72(d,J=8.00Hz,1H),4.74(s,1H),3.74(s,3H...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com