Knife device and tool holder for such a tool device

A tool and tool holder technology, applied to the accessories of tool holders, milling cutters, manufacturing tools, etc., to achieve the effect of avoiding freezing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

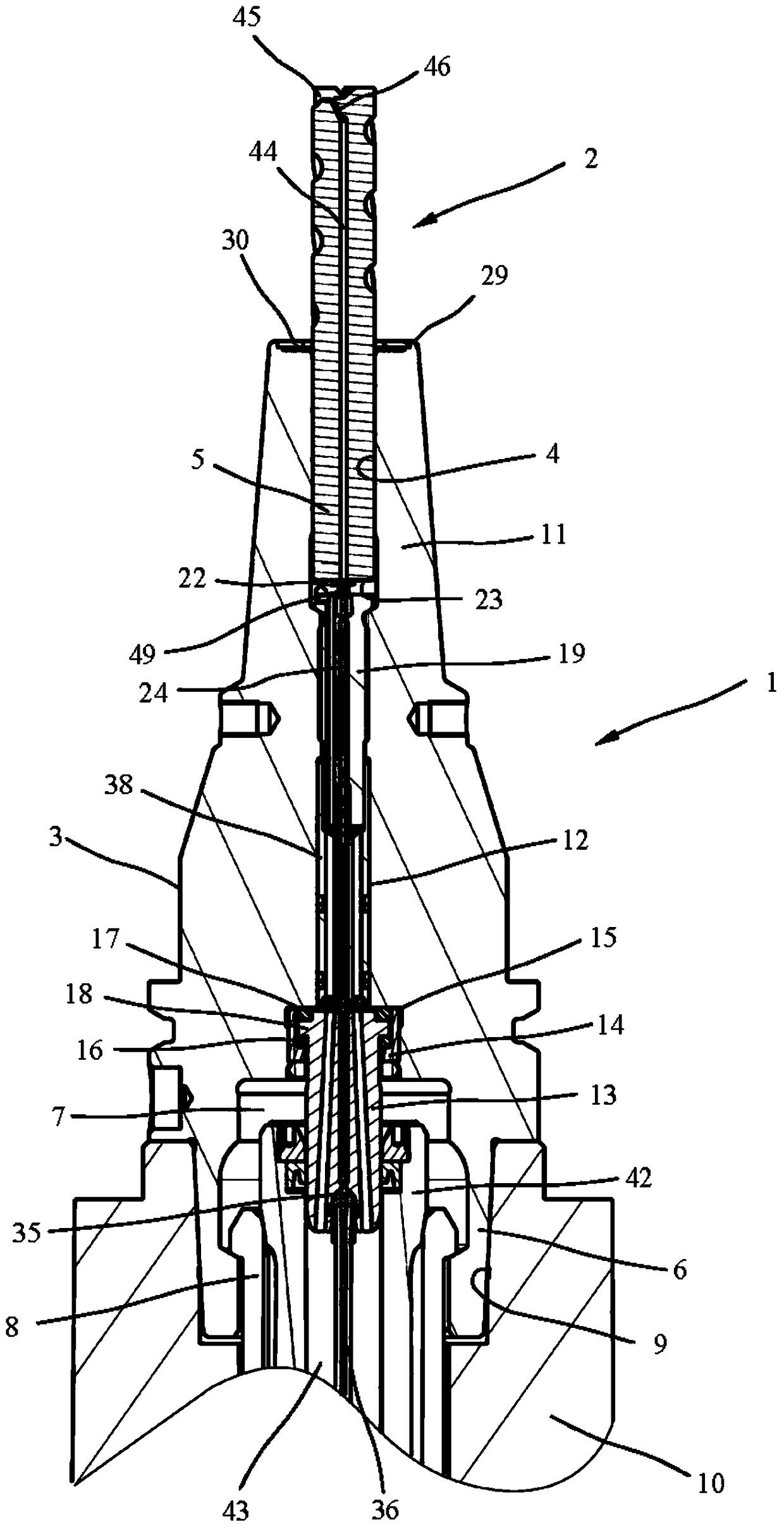

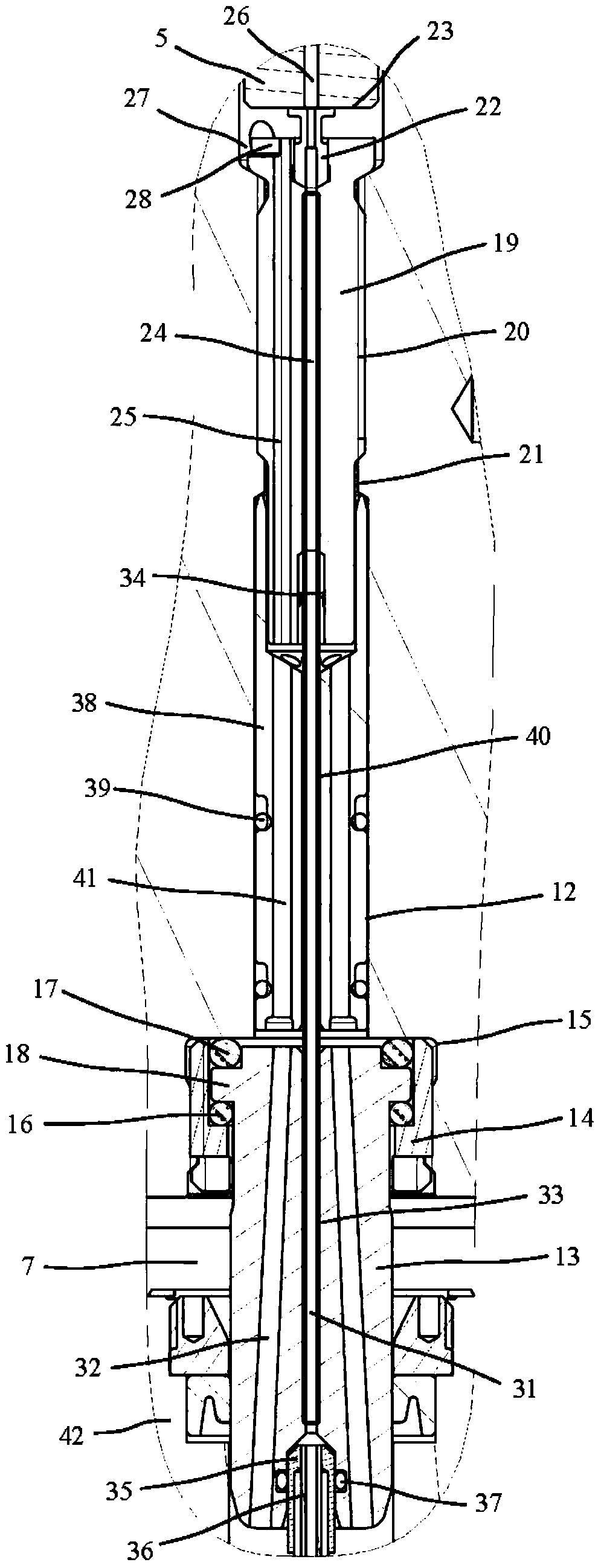

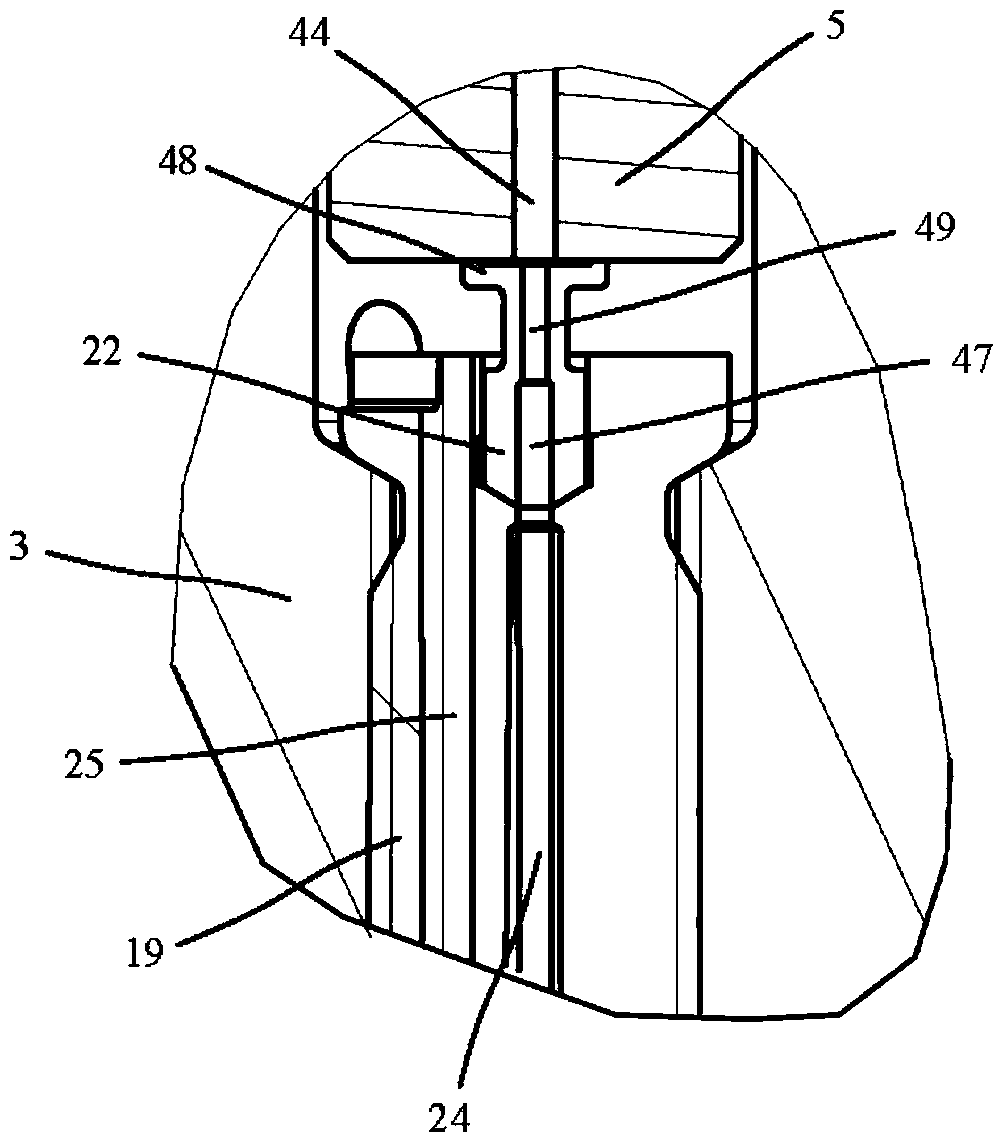

[0027] exist figure 1 An exemplary embodiment of a tool arrangement with a tool holder 1 and a tool 2 is shown in . Here, the tool holder 1, designed for example as an HSK (hollow taper shank, Hohlschaftkegel) tool holder, comprises a rotationally symmetrical tool holder body 3 that can rotate about a central axis, and which has, for example, a design on the tool-side end. A receiving hole 4 for a tool holder 5 of a tool 2 for a drill, milling cutter or the like, and on the end on the machine tool side comprises a clamping cone 6 which has a cavity 7 which Clamping part 8 for engaging the pliers. The tool holder 1 is mounted via a clamping cone 6 into a corresponding cone receptacle 9 of a machine tool spindle 10 and clamped via a pliers-shaped clamping part 8 of a clamping device integrated in the machine tool spindle 10 .

[0028] In the illustrated embodiment, the tool holder 1 is designed as a retractable collet and comprises a front clamping region 11 in which a tool ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com