ore crusher

A pulverizer and ore technology, which is applied in the field of particle ore or stone pulverization, can solve the problems of difficult lifting of the top column of the hammer system, unreasonable design and fixation of the hammer, and large loss of the transmission mechanism, so as to reduce the movement resistance. Small, reasonable force, the effect of reducing power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

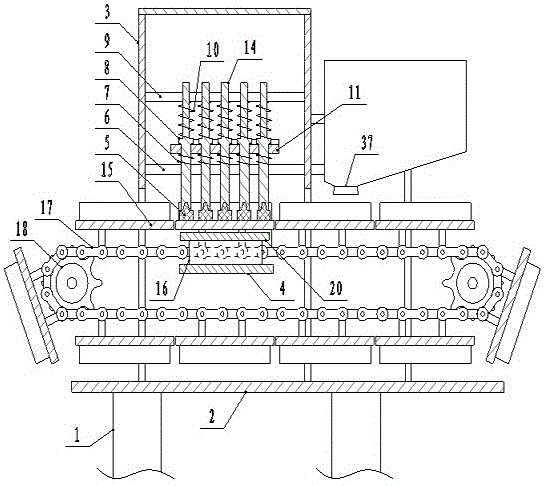

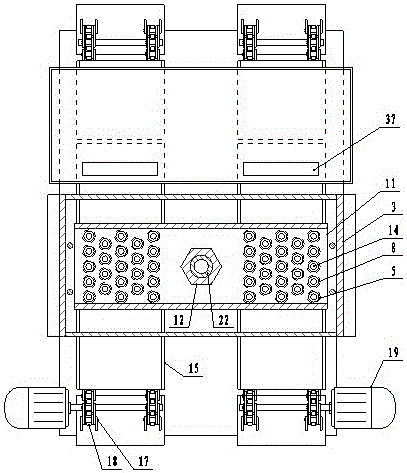

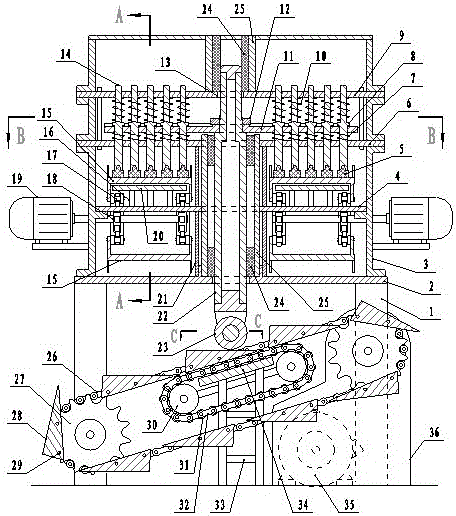

[0013] Example: such as figure 1 , figure 2 , image 3 and Figure 4 As shown, an ore pulverizer is composed of a frame, a hammer mechanism, a feeding mechanism, a jacking mechanism and a hopper. The frame is composed of a bracket 1, a bottom plate 2 and a chassis 3. It is square, installed above the bottom plate 2, the hammer mechanism is installed in the chassis 3, the feeding mechanism is installed in the middle of the chassis 3, the jacking mechanism is installed under the bottom plate 2, the hopper is installed on the side of the chassis, and the outlet 37 of the hopper is located in the feeding mechanism Above, the hammer material mechanism is composed of the central shaft 22, the material hammer 14, the upper fixed plate 9, the lifting tray 11, the lifting pan fixing nut 12 and the lower fixed plate 6. The central axis 22 is located at the center of the cabinet 3, and the central axis 22 is sleeved on the In the steel sleeve 25, a nylon sleeve 24 is installed betwee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com