A kind of heteropolyacid modified catalyst and its preparation and application

A technology of heteropolyacid and catalyst, which is applied in the field of heteropolyacid modified catalyst and its preparation and catalyzed oil esterification reaction system, which can solve problems such as difficult recovery, achieve high catalytic activity, mild esterification reaction conditions, and easy operation simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

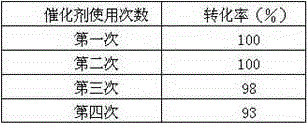

Examples

Embodiment 1

[0027] Dissolve 18.25g of 12-phosphomolybdic acid in 15ml of distilled water, dissolve 1.23g of 2-picolinic acid in 10ml of distilled water, and configure it into an aqueous solution. Under stirring conditions, add the 2-picolinic acid aqueous solution dropwise to the phosphomolybdic acid solution, add dropwise After stirring for 2 hours, the generated solid was separated and recovered, and dried at 100°C to obtain a 2-picolinic acid modified phosphomolybdic acid catalyst.

[0028] 1.41g of oleic acid, 1.602g of methanol and 0.14g of catalyst were added to a 25ml kettle reactor, reacted at 80°C for 8h, the catalyst was separated by centrifugation, and the reaction product was analyzed by GC-MS.

[0029] Under the above conditions, the conversion rate of oleic acid esterification reaches 100%.

Embodiment 2

[0031] Dissolve 18.25g of 12-phosphomolybdic acid in 15ml of distilled water, and dissolve 4.77g of 3-pyridinesulfonic acid in 15ml of distilled water to form an aqueous solution. Under stirring conditions, add the 3-pyridinesulfonic acid aqueous solution dropwise to the phosphomolybdic acid solution, After the dropwise addition was completed, the mixture was stirred for 6 h, and the generated solid was separated and recovered, and dried at 120° C. to obtain a 2-picolinic acid modified phosphomolybdic acid catalyst.

[0032] 1.41g of oleic acid, 1.92g of methanol and 0.07g of catalyst were added to a 25ml kettle reactor, reacted at 60°C for 10h, the catalyst was separated by centrifugation, and the reaction product was analyzed by GC-MS.

[0033] Under the above conditions, the conversion rate of oleic acid esterification reaches 100%.

Embodiment 3

[0035] Dissolve 28.8g of 12-phosphotungstic acid in 20ml of distilled water, and dissolve 3.18g of 3-pyridinesulfonic acid in 15ml of distilled water to form an aqueous solution. Under stirring, add the aqueous solution of 3-pyridinesulfonic acid dropwise to the phosphotungstic acid solution, After the dropwise addition was completed, the mixture was stirred for 4 hours, and the generated solid was separated and recovered, and dried at 100 °C to obtain a 2-pyridinesulfonic acid modified phosphotungstic acid catalyst.

[0036] 1.41g of oleic acid, 1.602g of methanol and 0.14g of catalyst were added to a 25ml kettle reactor, reacted at 80°C for 6h, the catalyst was separated by centrifugation, and the reaction product was analyzed by GC-MS.

[0037] Under the above conditions, the conversion rate of oleic acid esterification reaches 100%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com