A kind of supergravity reactor and reaction method

A high-gravity reactor and reaction technology, applied in chemical instruments and methods, chemical methods for reacting liquid and gaseous media, chemical/physical/physicochemical mobile reactors, etc., to achieve low compatibility requirements and broaden the range The effect of scope

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

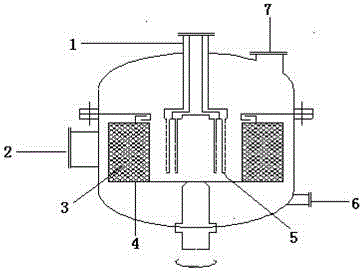

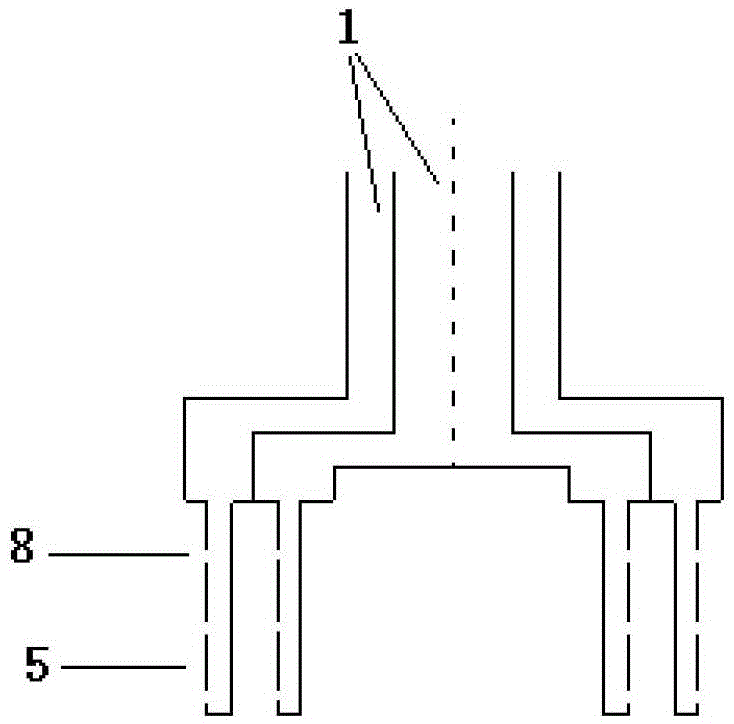

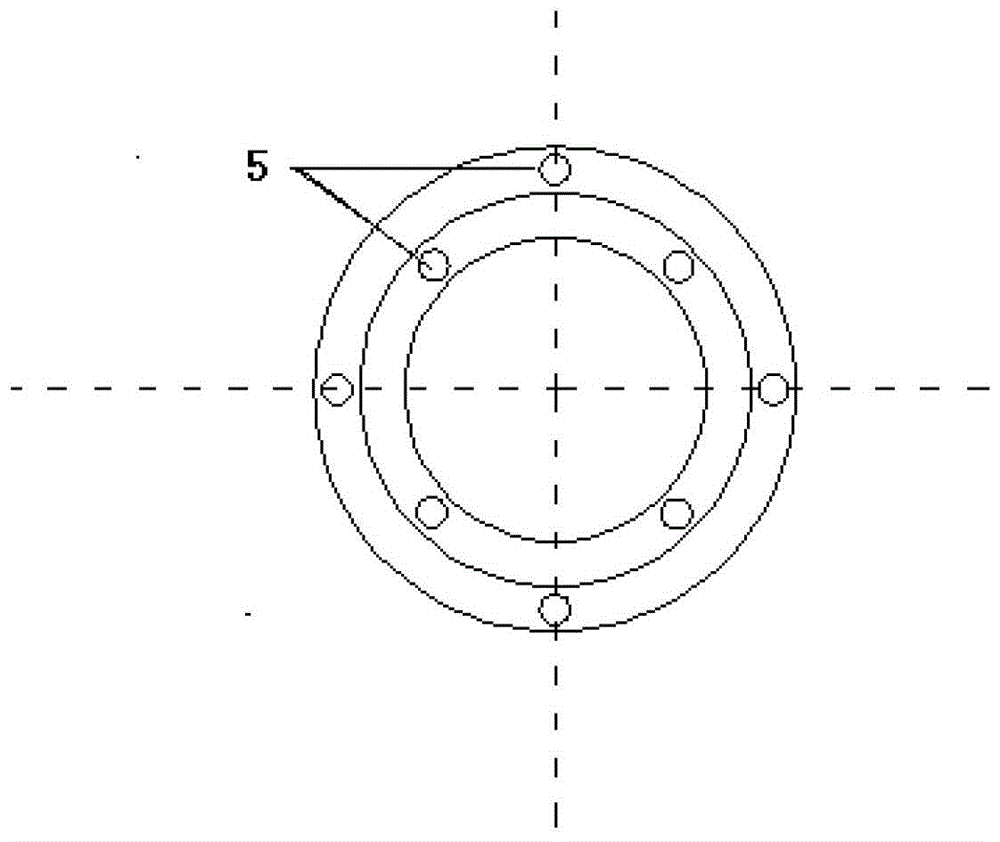

[0034] Such as figure 1 , figure 2 , image 3 Shown, a supergravity reactor. The high-gravity reactor 11 is provided with two liquid feed ports 1, and the two liquid feed ports 1 are respectively connected to respective liquid distributors, and the spray pipes 5 of the two liquid distributors are independent and arranged on a rotating bed On the concentric ring with the central axis as the center of the circle, the number of spray pipes of the two liquid distributors is the same and arranged at intervals in sequence.

[0035] Catalyst preparation: This catalyst uses a 1:1 mixture of nitric acid and hydrochloric acid to dissolve metal Pd, control the dissolved Pd particle size within the range of 5-50nm, and then use NaOH solution to adjust the pH value of the solution between 6.5-7, and finally Add deionized water to make aqueous catalyst. The active component Pd is evenly suspended (similarly dissolved) in the whole solution in the state of nanoparticles. During the prep...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com