Real-time feedback automatic assembling and manufacturing method for nano-electronic appliance

A real-time feedback, electronic device technology, applied in nanostructure manufacturing, semiconductor/solid-state device manufacturing, nanostructure assembly, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

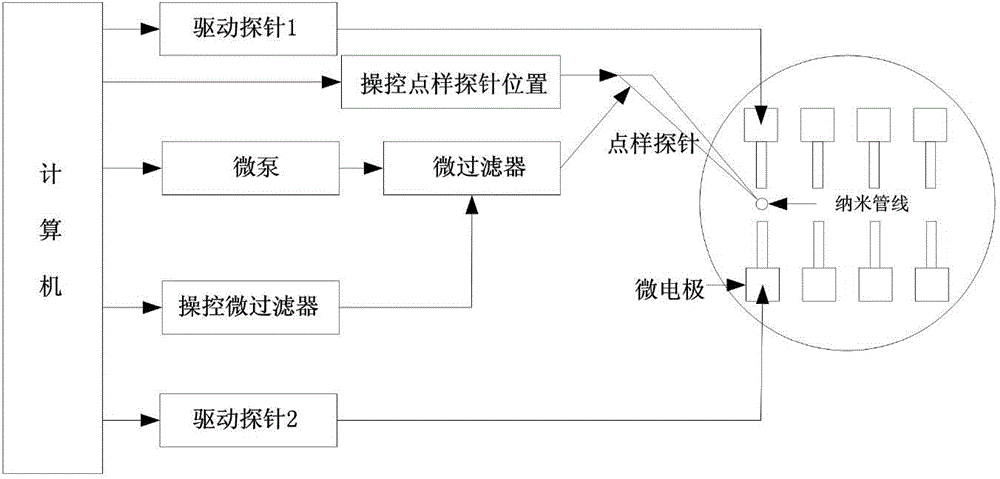

[0019] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0020] 1. Pretreatment of nanomaterials: put ZnO nanowires and alcohol mixed solution at a ratio of 1:1000 into a test tube, put the test tube into an ultrasonic oscillator at 30 degrees Celsius for 10-15 minutes, then take it out and stand still for 1 hour to obtain a uniform Translucent solution, obtain a large number of ZnO nanowire samples dispersed in the solution as a single;

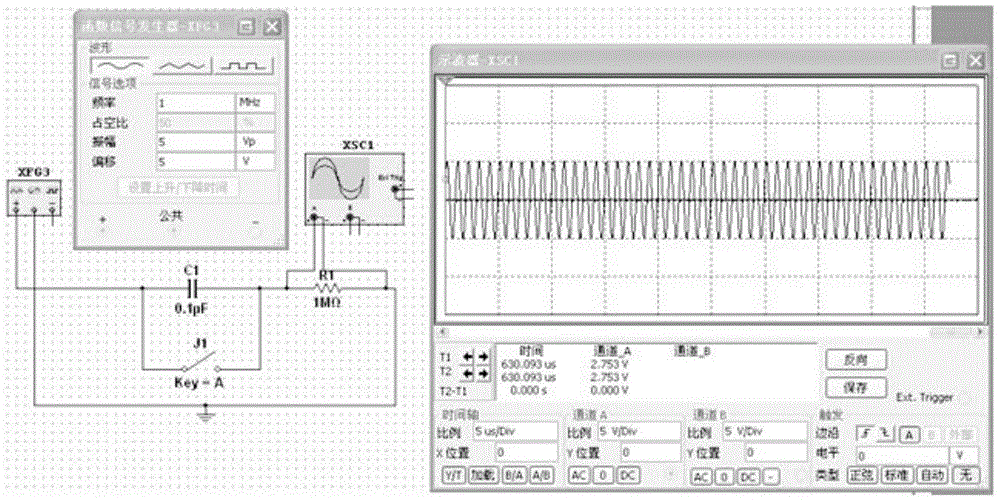

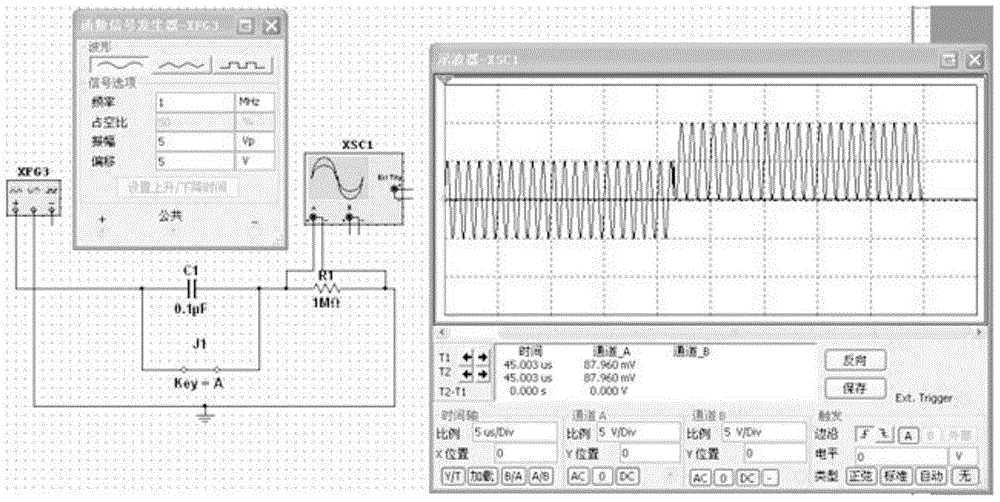

[0021] 2. Automatic assembly process based on a closed-loop control system: Since the distance between the source and drain electrodes is about 1 μm, it is equivalent to a capacitor in the circuit. When the ZnO nanowire is not overlapped, the AC signal can be transmitted through the electrode, and the DC signal will be blocked. ; When the medium is lapped at both ends of the electrode, the electrode and the medium are equivalent to a resistance, and both AC and DC signals can be ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com