A Method for Predicting the Coking Amount of Heavy Oil Catalytic Cracking Settler

A technology of settler and coking quantity, which is applied in the direction of instruments, special data processing applications, electrical digital data processing, etc., and can solve problems such as unplanned shutdown of refinery equipment and coking problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] The specific steps of coking amount prediction are as follows:

[0049] (1) Obtain basic data related to condensation rate, capture rate, and coke formation rate, as well as actual values of condensation rate, capture rate, and coke formation rate; see Tables 1-3 for some data;

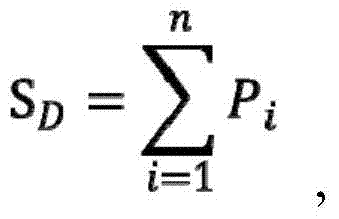

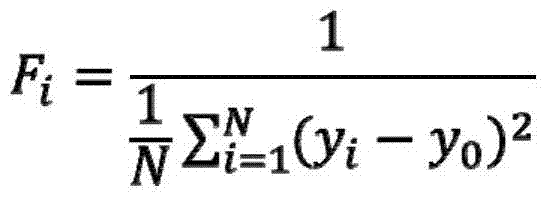

[0050] (2) Among the 100 groups of data obtained in step (1), randomly select 60 groups as training data, and 40 groups as verification data, using the method described in the summary of the invention BP neural network Obtain models to predict settler condensation, capture and coking rates;

[0051] (3) The basic data of the heavy oil catalytic cracking settler are collected on site and preprocessed, and one set of data obtained after pretreatment is respectively substituted into the condensation rate, capture rate, and coke formation rate model obtained in step (2) to obtain the settler Predicted values of condensation rate, capture rate and coking rate; collect the mass flow rate of oil ...

Embodiment 2

[0054] Compared with Example 1, the only difference is: in 100 groups of basic data, 80 groups are randomly selected as training data, 20 groups are used as verification data, and the method described in the summary of the invention is used GRNN neural network Build a model to predict condensation rate, capture rate, and coke rate; predict the amount of coking in the catalytic cracking settler unit of A refinery; the prediction results are shown in Table 4.

Embodiment 3

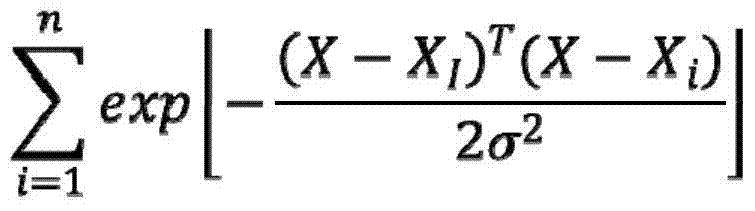

[0056] Compared with Example 1, the only difference is that among 100 sets of basic data, 80 sets are randomly selected as training data, and 20 sets are used as verification data using the method described in the Summary of the Invention. RBF neural network Construct the models of condensation rate, capture rate and coke generation rate; predict the amount of coking in the catalytic cracking settler unit of A refinery; the prediction results are shown in Table 4.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com