Analyzing method of gas discharge experiment under unconventional condition

A gas discharge and experimental analysis technology, applied in the direction of testing dielectric strength, etc., can solve problems such as inability to interpret air gap discharge signal information, backward test methods, and inability to accurately obtain the state of the discharge process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

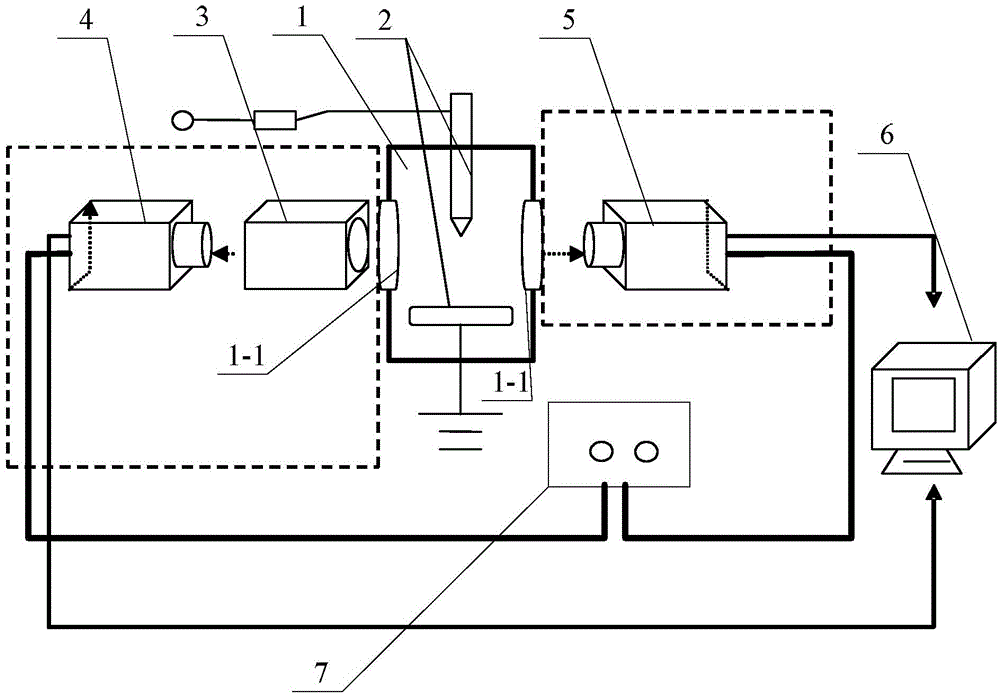

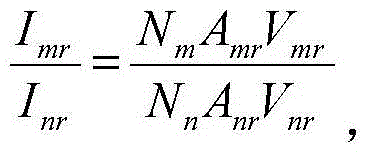

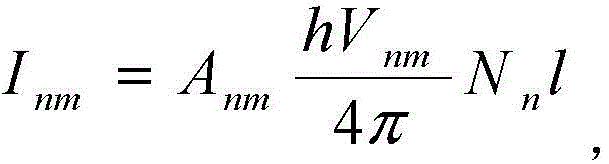

[0035] Specific implementation mode one: the following combination figure 1 Describe this embodiment, the gas discharge experimental analysis method under unconventional conditions described in this embodiment, it realizes based on the gas discharge experimental device under unconventional conditions, this experimental device includes airtight discharge chamber 1, bar plate copper electrode 2, monochromator 3. Optical image collector 4, discharge image collector 5 and computer 6,

[0036] The bar plate copper electrode 2 is arranged in the airtight discharge chamber 1, there is a gap between the head end of the bar part of the bar plate copper electrode 2 and the plate part, the plate part is connected to the power supply ground, and the end of the bar part is connected to the high voltage power supply through a resistor ;

[0037] Two opposite side walls of the airtight discharge chamber 1 are respectively provided with quartz glass windows 1-1, and the two opposite side wal...

specific Embodiment approach 2

[0058] Specific implementation mode two: this implementation mode will further describe the first embodiment mode, the particle density N e for:

[0059] N e = I 0 g + A + V + 2 ( 2 π m e kT ) 3 / 2 I + g 0 A 0 V 0 ...

specific Embodiment approach 3

[0083] Specific implementation mode three: the following combination figure 1 For illustration, this embodiment will further illustrate the first or second embodiment, the experimental device also includes a synchronizer 7,

[0084] The synchronization signal output terminal of the synchronizer 7 is connected to the synchronization signal input terminals of the optical image collector 4 and the discharge image collector 5 at the same time.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com