Visual experiment device and method for simulating fracture-vug type carbonatite oil reservoir gas injection

A carbonate rock reservoir and experimental device technology, which is applied in the field of simulating gas injection in fractured-cavity carbonate reservoirs and visual experimental device, and can solve problems such as poor visual experimental effect and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

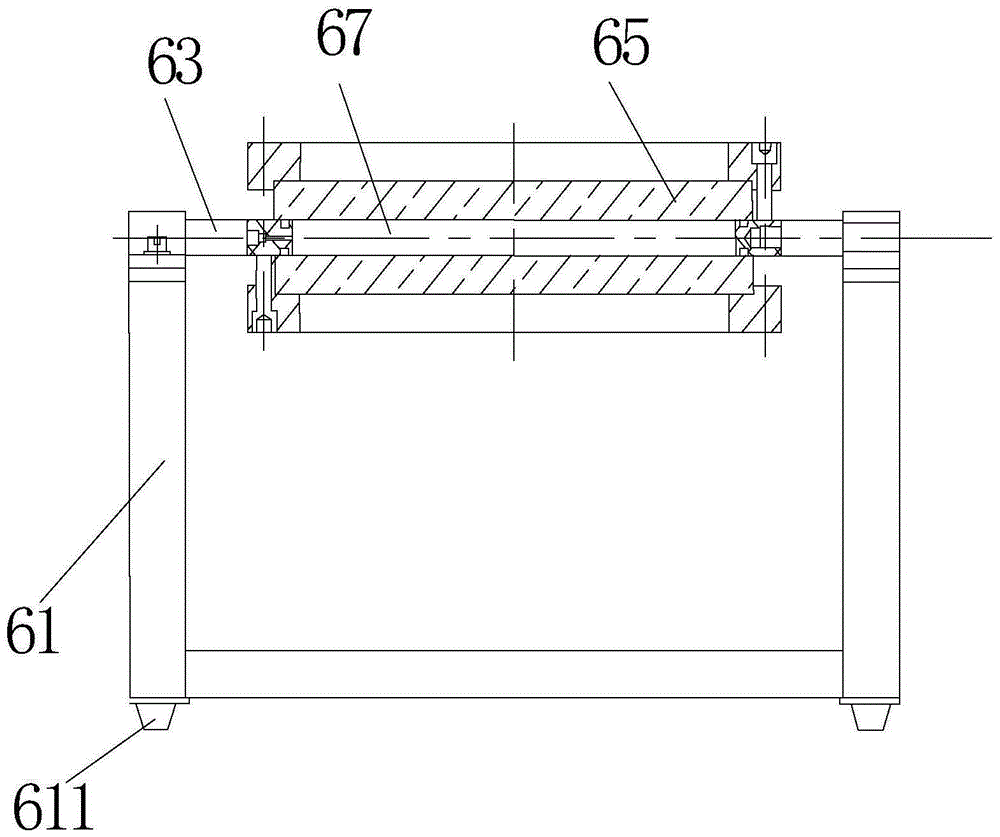

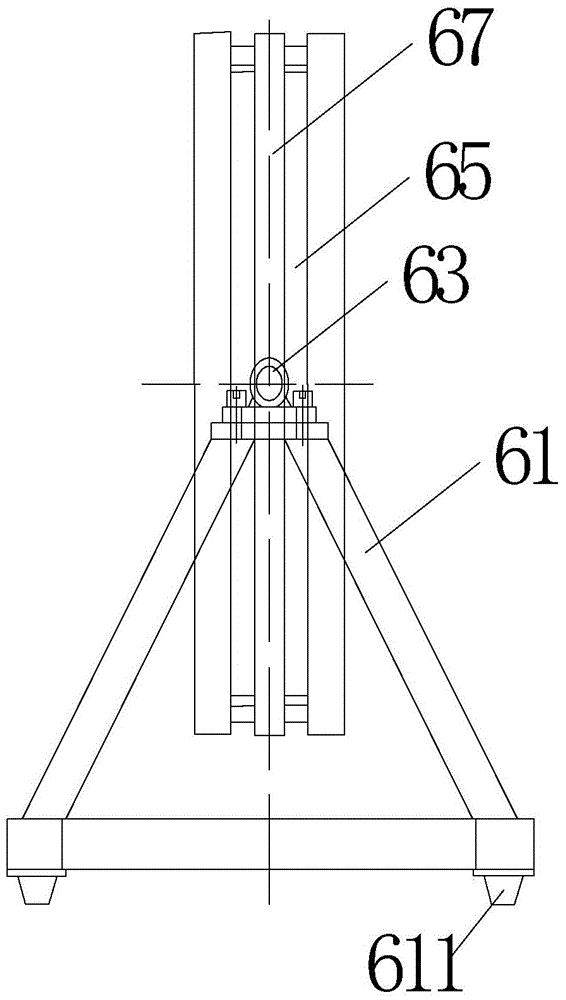

[0052] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the present invention will now be described with reference to the accompanying drawings.

[0053] Such as Figure 4As shown, the visualized experimental device for simulating gas injection in fracture-cavity carbonate reservoirs of the present invention includes the following experimental devices: computer 1 or microcomputer, camera 2, visualized core clamping device 6, light source 7, simulated formation water Piston container 11, formation simulation oil piston container 12, gas piston container 13, advection pump 15, six-way valve 14, pressure gauge, balance pressure device 5, (corrosion-resistant) back pressure valve 3, oil, gas and water metering device 4, gas cylinder 10. Gas flow meter 9, three-way valve 8, valve 16, valve 17, valve 18, valve 19, valve 20, valve 21, valve 22, valve 23, valve 24, valve 25, outlet 26, outlet 27, outlet 28, outlet 29, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com