YSZ-based mixed-potential type NH3 sensor with Ni3V2O8 serving as sensitive electrode and preparation method of YSZ-based mixed-potential type NH3 sensor with Ni3V2O8 serving as sensitive electrode

A hybrid potential-type and sensitive electrode technology, which is applied in the direction of instruments, scientific instruments, and electrochemical variables of materials, can solve the problems of insufficient selectivity, impracticality, and low response value, and achieve good thermal stability and chemical stability. The effect of stability, high sensitivity, and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

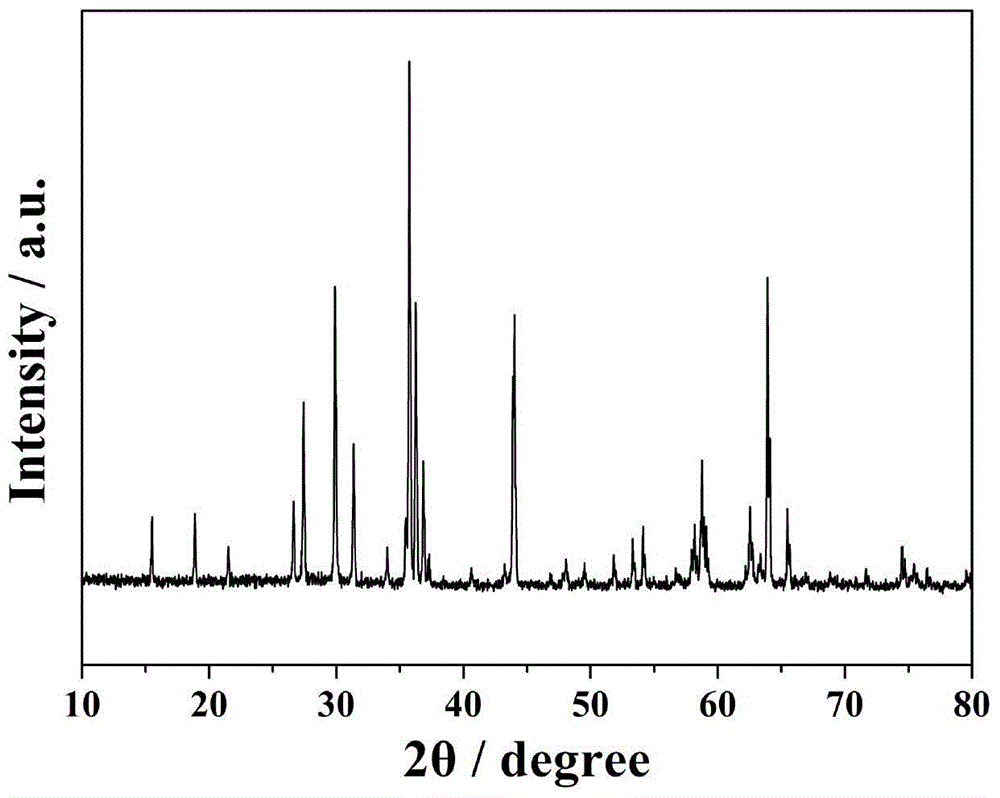

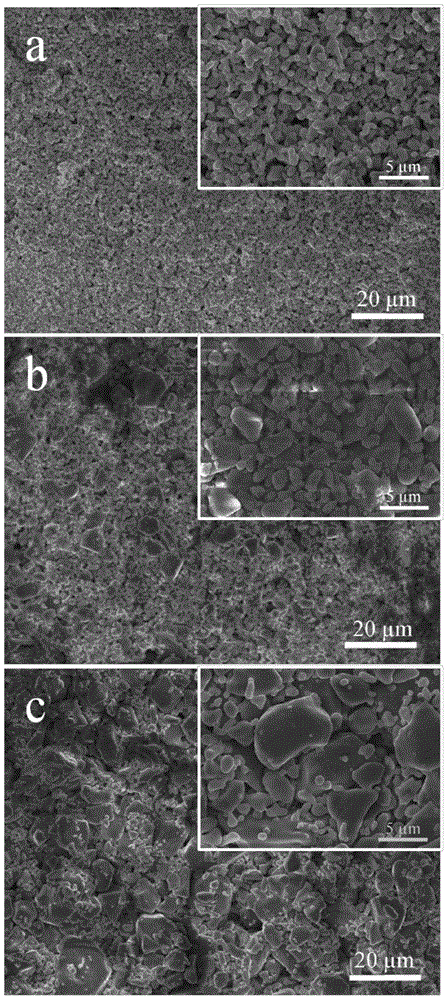

[0038] Preparation of Ni by Sol-Gel Method 3 V 2 o 8 material, 800°C sintered Ni 3 V 2 o 8(800℃) Fabrication of YSZ-based hybrid potential NH as sensitive electrode material 3 sensor, and test the gas sensitivity performance of the sensor, the specific process is as follows:

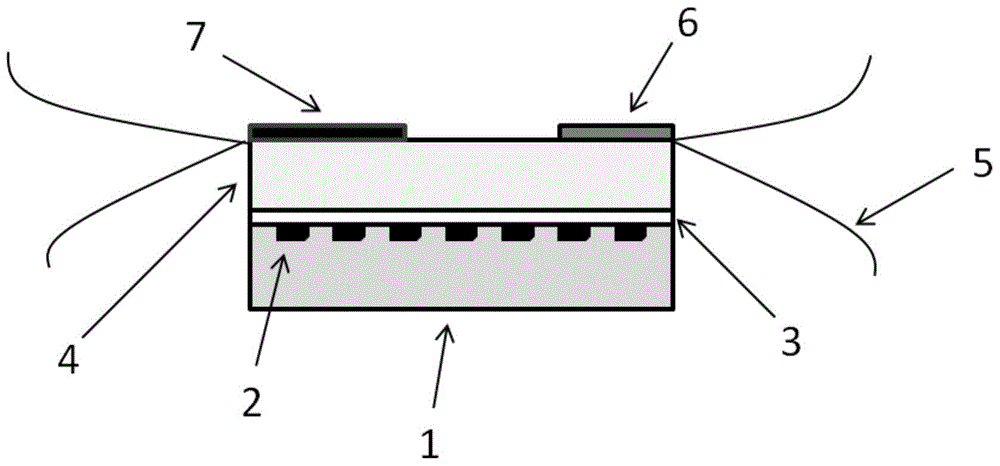

[0039] 1. Make a Pt reference electrode: use Pt slurry to make a Pt reference electrode with a size of 0.5mm×2mm and a thickness of 15μm on one end of the upper surface of the YSZ substrate with a length and width of 2×2mm and a thickness of 0.2mm, and fold it in half with a Pt wire Then stick the electrode lead wire on the middle position of the reference electrode; then bake the YSZ substrate at 100°C for 1.5 hours, and then sinter the YSZ substrate at 1100°C for 1.5 hours, so as to eliminate the terpineol in the platinum paste, and finally reduce the to room temperature.

[0040] 2. Make Ni 3 V 2 o 8 Sensitive electrode: first prepare Ni by sol-gel method 3 V 2 o 8 Material. Weigh 3mmol ...

Embodiment 2

[0046] Ni sintered at 1200°C 3 V 2 o 8 material as a sensitive electrode material, making NH 3 The sensor, its manufacturing process is:

[0047] The Ni prepared by the aforementioned method 3 V 2 o 8 Sensitive electrode material Ni was obtained by sintering at 1200°C in a muffle furnace 3 V 2 o 8(1200℃) , the device manufacturing process is the same as in Example 1.

Embodiment 3

[0049] Ni sintered at 1000°C 3 V 2 o 8 material as a sensitive electrode material, making NH 3 The sensor, its manufacturing process is:

[0050] The Ni prepared by the aforementioned method 3 V 2 o 8 Sensitive electrode material Ni was obtained by sintering at 1000°C in a muffle furnace 3 V 2 o 8(1000℃) , the device manufacturing process is the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com