A kind of strain gauge and its manufacturing and installation method

A manufacturing method and technology of strain gages, which are applied in electromagnetic measuring devices, electric/magnetic solid deformation measurement, etc., can solve the problem of high technical level requirements of the personnel installing strain gages, inability to achieve high precision, long-term testing, and installation of strain gages. Time and other issues, to achieve the effect of high test accuracy, high strength and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described in detail below in conjunction with the accompanying drawings, which are explanations rather than limitations of the present invention.

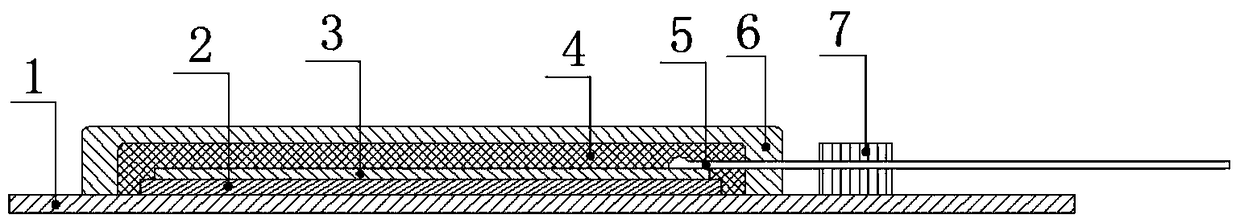

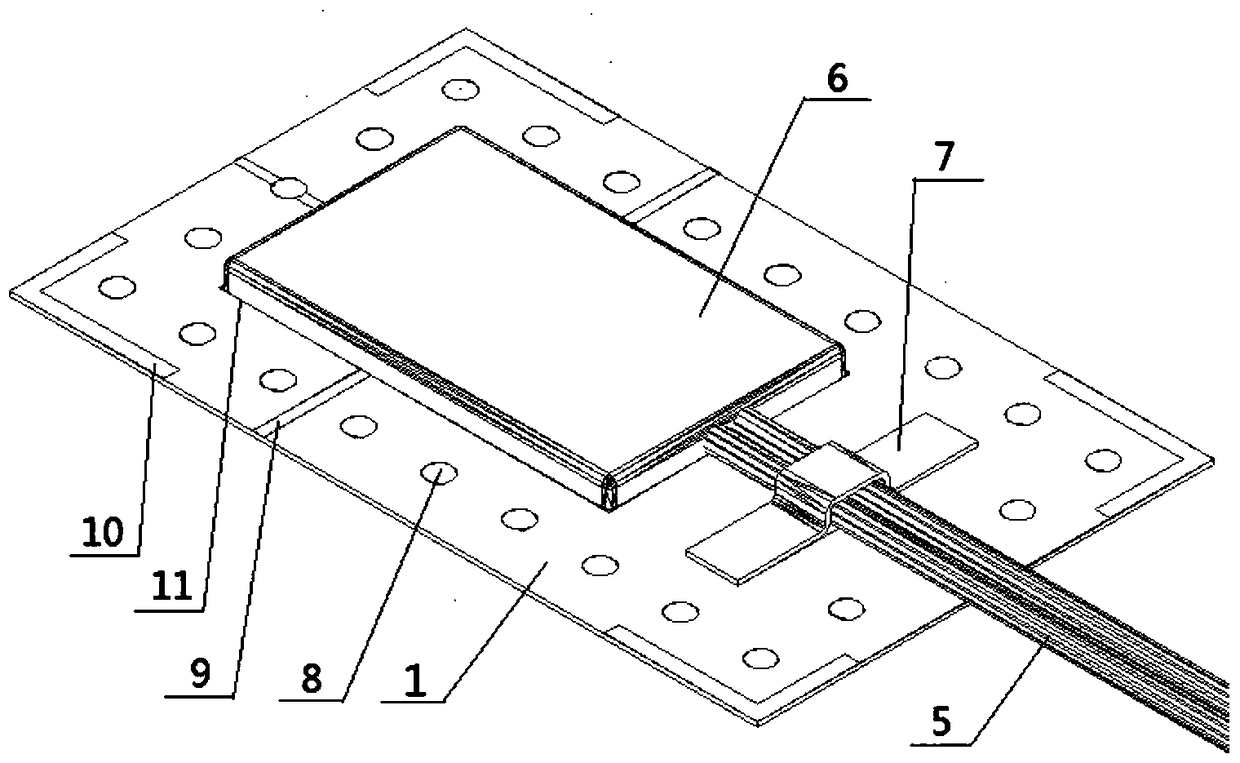

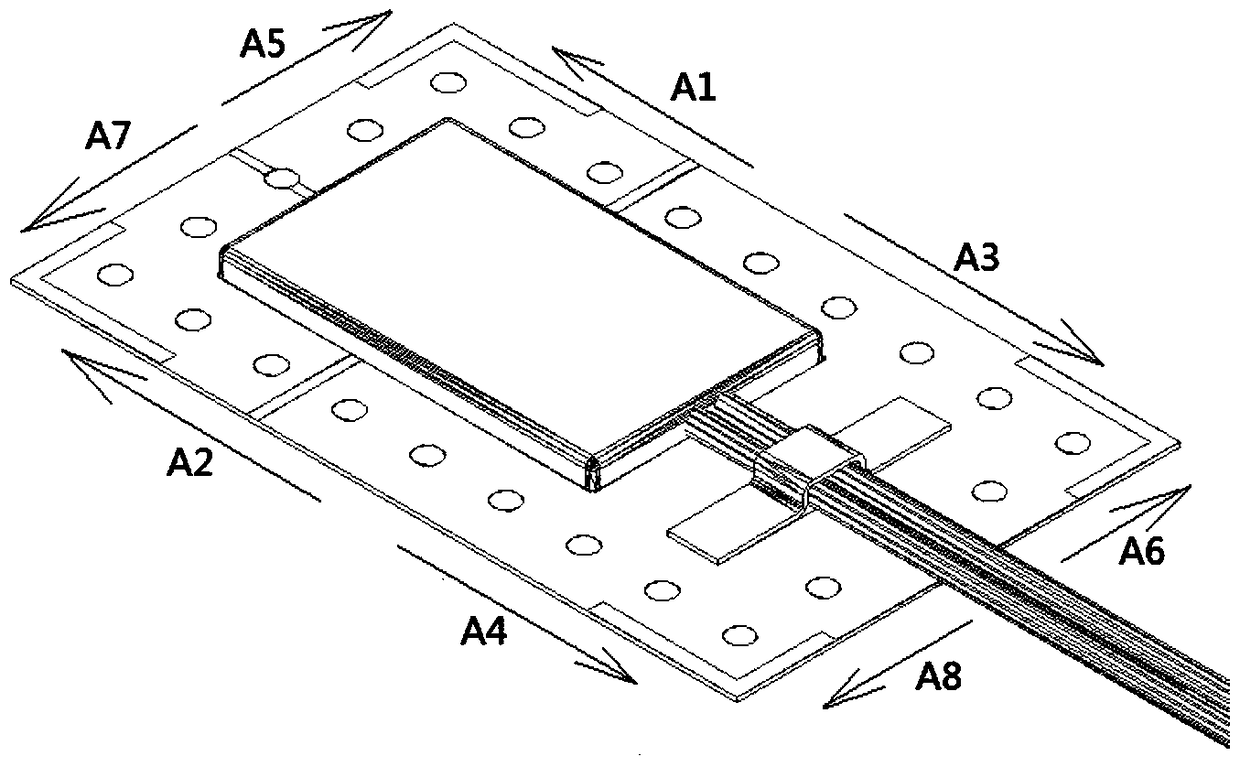

[0033] A kind of strain gauge of the present invention, as figure 1 As shown, it includes a metal base body 1, an adhesive layer 2, a resistance strain gauge 3, a moisture-proof layer 4, a signal lead 5 and a protective layer 6; the resistance strain gauge 3 is fixedly installed on the metal base body 1 through the adhesive layer 2 ; The signal lead 5 is electrically connected to the pad of the resistance strain gauge 3 and drawn; the moisture-proof layer 4 is coated on the surface of the resistance strain gauge 3, and its coverage area is greater than the surface area of the resistance strain gauge 3, and the coating edge of the moisture-proof layer 4 is fixed on the surface of the resistance strain gauge 3. On the metal base body 1; the protection layer 6 is coated on the surface of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com