Method for replacing rubber isolation bearing

A replacement method and technology of vibration isolation rubber, applied in the direction of building maintenance, construction, building structure, etc., can solve the problems of inability to directly install the jack, insufficient vulcanization time, bulging, etc., so as to achieve a simple and fast introduction process and improve construction safety. , the effect of preventing natural rebound

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

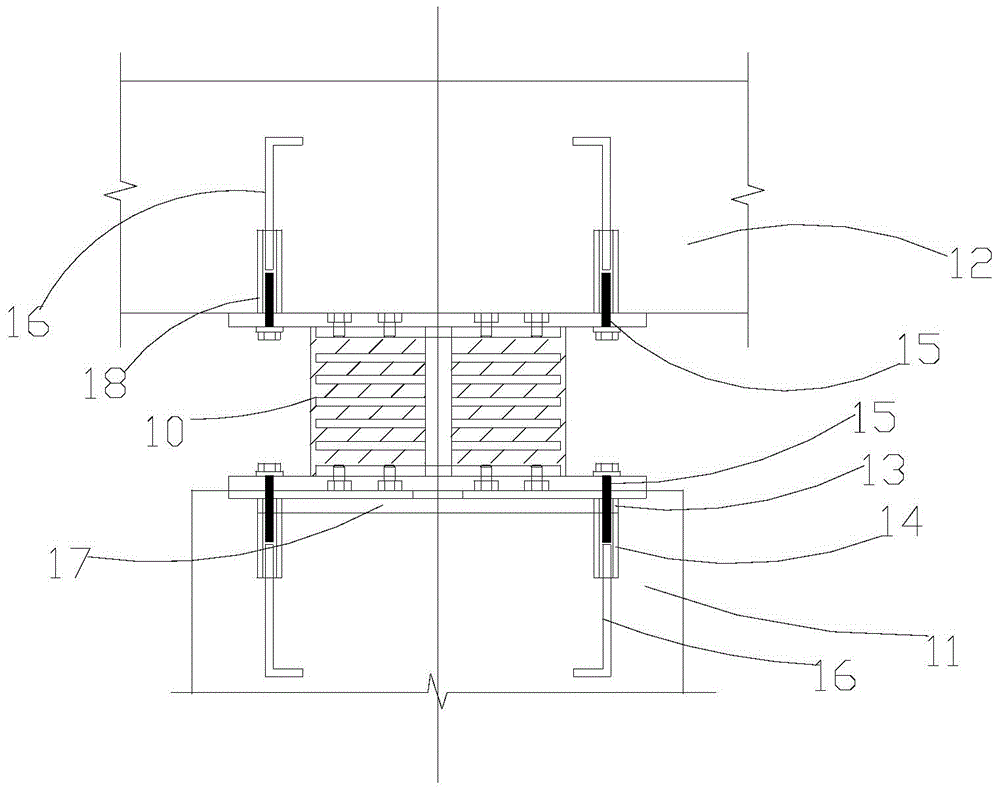

[0037] Specific embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

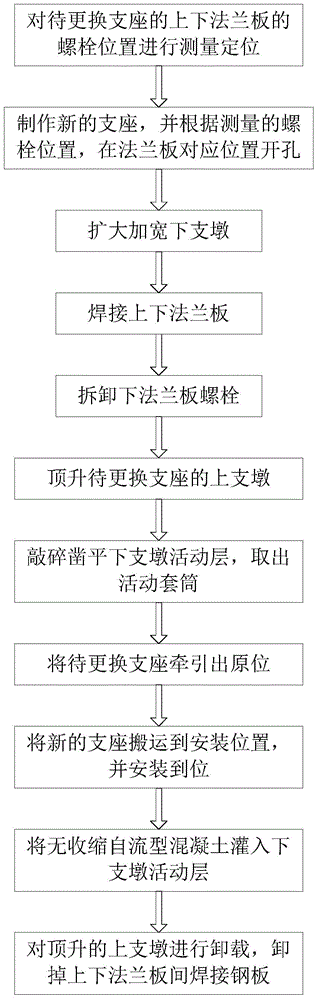

[0038] See figure 2 , which is a flow chart of an embodiment of the method for replacing a vibration-isolation rubber bearing of the present invention, including the following steps:

[0039] (1) Measure and locate the bolt positions of the upper and lower flange plates of the shock-isolation bearing to be replaced.

[0040] (2) Make a new shock-isolation support, and drill holes at the corresponding positions on the flange plate according to the measured bolt positions.

[0041] (3) Expand and widen the lower buttress.

[0042] (4) Weld the upper and lower flange plates of the shock-absorbing support with steel plates.

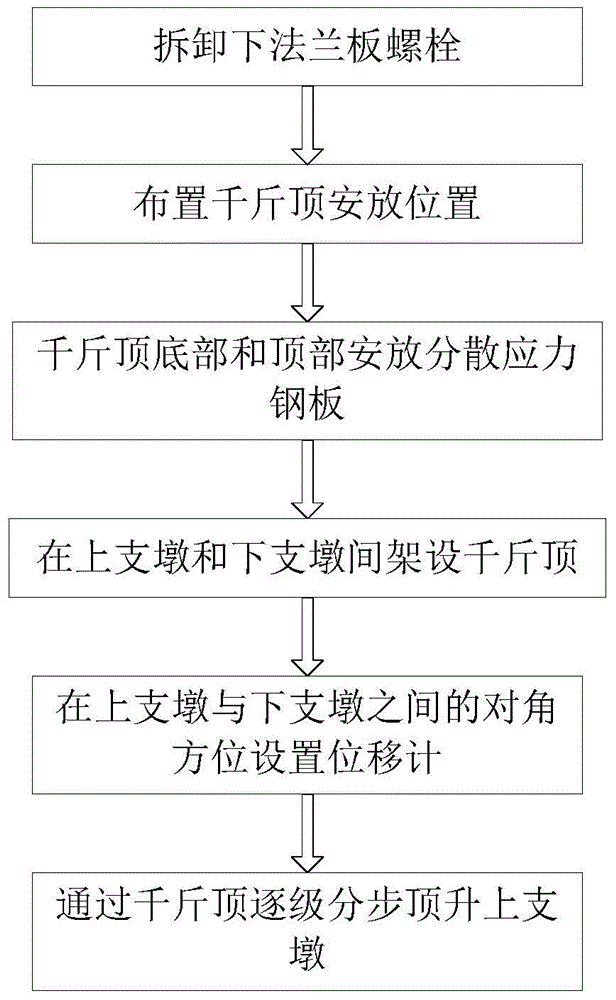

[0043] (5) Remove the flange plate bolts under the support.

[0044] (6) Lift the upper pier of the shock-isolation bearing to be replaced.

[0045] (7) Crush and chisel the movable layer of the lower pier, and take out t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com