Polyhedron CdSe/ZnSe/ZnS core-shell structure quantum dot capable of emitting strong red-yellow light and preparation method of polyhedron CdSe/ZnSe/ZnS core-shell structure quantum dot

A core-shell structure and quantum dot technology is applied in the field of polyhedral CdSe/ZnSe/ZnS core-shell structure quantum dots and their preparation, and achieves the effects of high yield, easy and accurate weighing, and environmental protection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

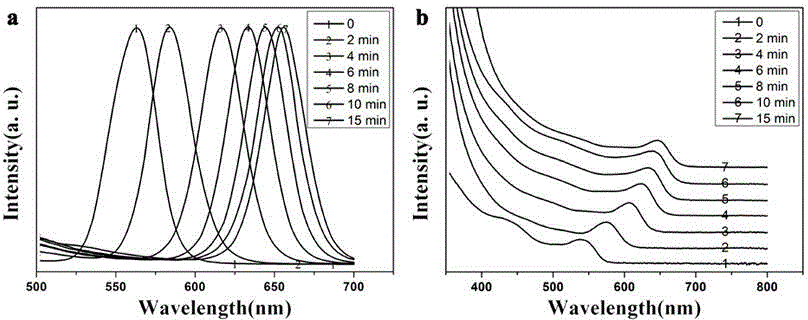

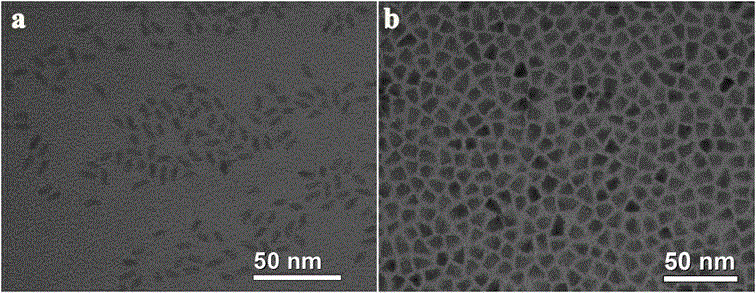

Image

Examples

Embodiment 1

[0043](1) Stir under a nitrogen atmosphere, dissolve selenium powder in tri-n-octylphosphine TOP, and make a TOP-Se solution with a concentration of 0.5 moles per liter; dissolve sulfur powder in TOP to make a concentration of 0.375 moles per liter TOP-S solution; dissolving zinc oxide ZnO in octadecylphosphonic acid ODPA and N235 with 2.1 times the number of moles to form an ODPA-Zn solution with a concentration of 0.23 moles per liter;

[0044] (2) Add cadmium oxide CdO 0.15mmol, ODPA 0.32mmol and N235 5mL into a four-necked flask, and heat to 310 o C, keep warm for 3 minutes after the solution is colorless, clear and transparent;

[0045] (3) Under rapid stirring, inject 1 mL of TOP-Se solution, wherein the Se content is 0.5 mmol, and the injection time is 0.25 minutes;

[0046] (4) After 2 minutes, the solution turns orange red, inject 70 o 1 mL of ODPA-Zn solution of C, wherein the Zn content is 0.23 mmol, and the injection time is 1.5 minutes;

[0047] (5) After keepi...

Embodiment 2

[0055] (1) Stir under a nitrogen atmosphere, dissolve selenium powder in tri-n-octylphosphine TOP, and make a TOP-Se solution with a concentration of 0.5 moles per liter; dissolve sulfur powder in TOP to make a concentration of 0.375 moles per liter TOP-S solution; dissolving zinc oxide ZnO in 2.3 times the number of moles of ODPA and N235 to form an ODPA-Zn solution with a concentration of 0.1 moles per liter;

[0056] (2) Add cadmium oxide CdO 0.12mmol, ODPA 0.27mmol and N235 5mL into a four-necked flask, and heat to 310 o C, keep warm for 3 minutes after the solution is colorless, clear and transparent;

[0057] (3) Under rapid stirring, inject 1 mL of TOP-Se solution, wherein the Se content is 0.5 mmol, and the injection time is 0.25 minutes;

[0058] (4) After 1.5 minutes, the solution turns red, inject 70 o 1 mL of ODPA-Zn solution of C, in which the Zn content is 0.1 mmol, and the injection time is 1 minute;

[0059] (5) After keeping warm for 1.5 minutes, the soluti...

Embodiment 3

[0067] (1) Stir under a nitrogen atmosphere, dissolve selenium powder in tri-n-octylphosphine TOP, and make a TOP-Se solution with a concentration of 0.5 moles per liter; dissolve sulfur powder in TOP to make a concentration of 0.375 moles per liter TOP-S solution; dissolving zinc oxide ZnO in ODPA2.1 times the number of moles and N235 to form an ODPA-Zn solution with a concentration of 0.1 moles per liter;

[0068] (2) Add cadmium oxide CdO 0.12mmol, ODPA 0.27mmol and N235 5mL into a four-necked flask, and heat to 310 o C, keep warm for 3 minutes after the solution is colorless, clear and transparent;

[0069] (3) Under rapid stirring, inject 1 mL of TOP-Se solution, wherein the Se content is 0.5 mmol, and the injection time is 1.5 minutes;

[0070] (4) After 2 minutes, the solution turns red, inject 70 o 1.5 mL of ODPA-Zn solution of C, in which the Zn content is 0.15 mmol, and the injection time is 1.5 minutes;

[0071] (5) After keeping warm for 2 minutes, the solution ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com