Preparation method of chromatophilous polyurethane applied to superfine fiber synthetic leather

A technology of superfine fiber and synthetic leather, which is applied in the field of preparation of easy-to-dye polyurethane for superfine fiber synthetic leather, which can solve the problems of difficult dyeing, poor level dyeing, poor color fastness, etc., and achieve enhanced dyeing effect and improved hygienic performance , the effect of increasing the number

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

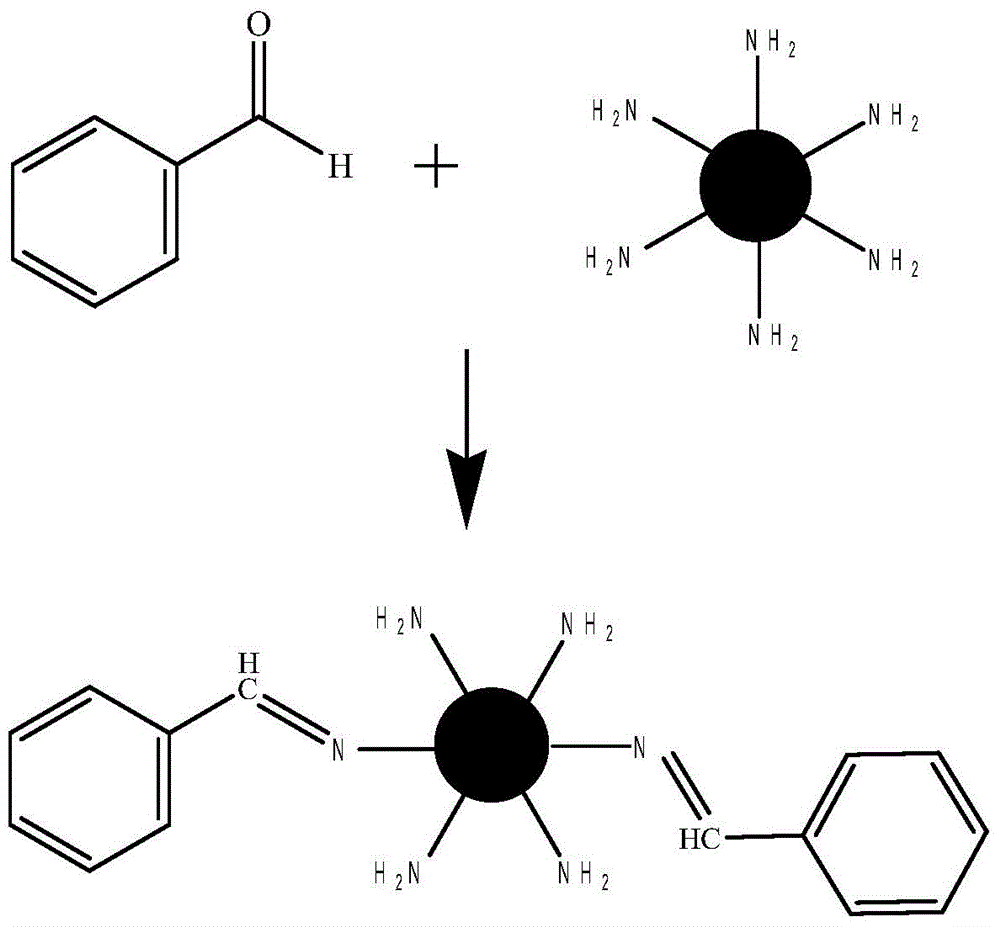

[0029] see figure 1 , figure 2 and image 3 , a kind of preparation method of easy dyeing polyurethane for superfine fiber synthetic leather, comprises the steps:

[0030] 1) Weigh 39.9g of polytetrahydrofuran ether glycol 2000 (abbreviated as PTMG2000) and dissolve it in 60ml of dried N,N-dimethylformamide (abbreviated as DMF);

[0031] 2) Under the condition of nitrogen protection, according to the molar ratio of -NCO and -OH as 2:1, with 0.007% dibutyltin dilaurate (abbreviated as DBTDL) as the catalyst, add 8.88g of isophorone di Isocyanate (abbreviated as IPDI) was stirred and reacted with polyether polyol at 75°C for 1.5h to obtain -NCO-terminated polyurethane prepolymer (abbreviated as PPU-PTMG);

[0032] 3) Weigh 14.88g of amino-terminated hyperbranched polymer and 1.06g of benzaldehyde and dissolve them in 60ml and 8ml of dried N,N-dimethylformamide (abbreviated as DMF), respectively.

[0033] 4) Under the condition of nitrogen protection, according to -CHO and -...

Embodiment 2

[0037] see figure 1 , figure 2 and image 3 , a kind of preparation method of easy dyeing polyurethane for superfine fiber synthetic leather, comprises the steps:

[0038] 1) Weigh 39.9g of polyethylene glycol 2000 (abbreviated as PEG2000) and dissolve it in 65ml of dried N,N-dimethylacetamide (abbreviated as DMAC);

[0039] 2) Under the condition of nitrogen protection, according to the molar ratio of -NCO and -OH as 2:1, with 0.007% dibutyltin dilaurate (abbreviated as DBTDL) as the catalyst, add 8.88g of isophorone di Isocyanate (abbreviated as IPDI) was stirred and reacted with polyether polyol at 75°C for 1.5h to obtain -NCO-terminated polyurethane prepolymer (abbreviated as PPU-PEG);

[0040] 3) Weigh 35.72g of amino-terminated hyperbranched polymer and 2.12g of benzaldehyde and dissolve them in 150ml and 15ml of dried N,N-dimethylacetamide (abbreviated as DMAC), respectively.

[0041] 4) Under the condition of nitrogen protection, according to -CHO and -NH 2 The m...

Embodiment 3

[0045] see figure 1 , figure 2 and image 3 , a kind of preparation method of easy dyeing polyurethane for superfine fiber synthetic leather, comprises the steps:

[0046] 1) Weigh 39.9g of polypropylene glycol 2000 (abbreviated as PPG2000) and dissolve it in 65ml of dried N,N-dimethylformamide (abbreviated as DMF);

[0047] 2) Under the condition of nitrogen protection, according to the molar ratio of -NCO and -OH as 2:1, with 0.007% dibutyltin dilaurate (abbreviated as DBTDL) as the catalyst, add 8.88g of isophorone di Isocyanate (abbreviated as IPDI) was stirred and reacted with polyether polyol at 75°C for 1.5h to obtain -NCO-terminated polyurethane prepolymer (abbreviated as PPU-PPG);

[0048] 3) Weigh 14.88g of amino-terminated hyperbranched polymer and 1.06g of benzaldehyde and dissolve them in 65ml and 10ml of dried N,N-dimethylformamide (abbreviated as DMF), respectively.

[0049]4) Under the condition of nitrogen protection, according to -CHO and -NH 2 The mola...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com