Automatic material distributing mechanism and material distributing method thereof

A sorting mechanism and automatic technology, applied in the direction of conveyor objects, transportation and packaging, etc., can solve the problems of occupation, high labor cost, low production capacity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

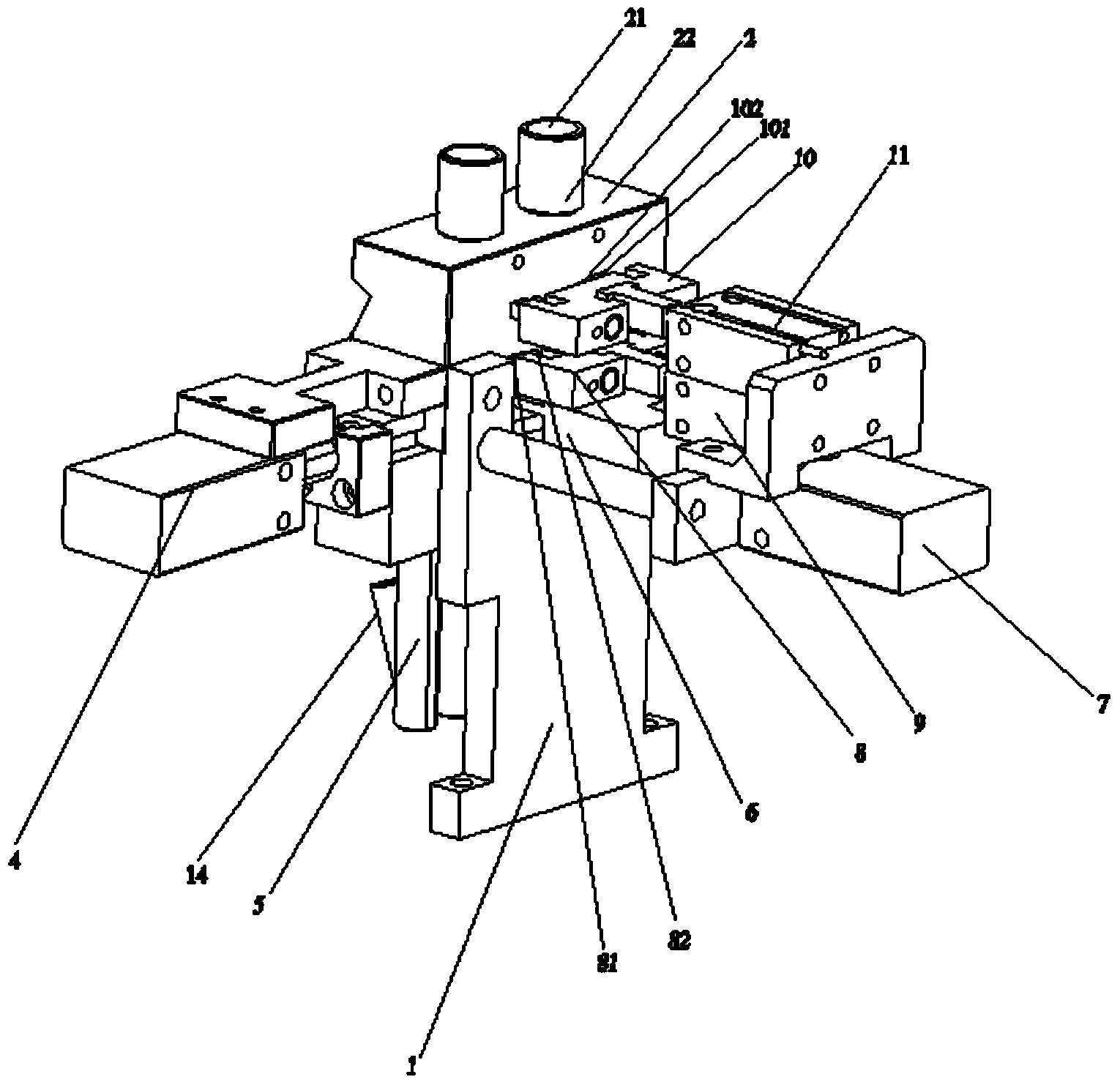

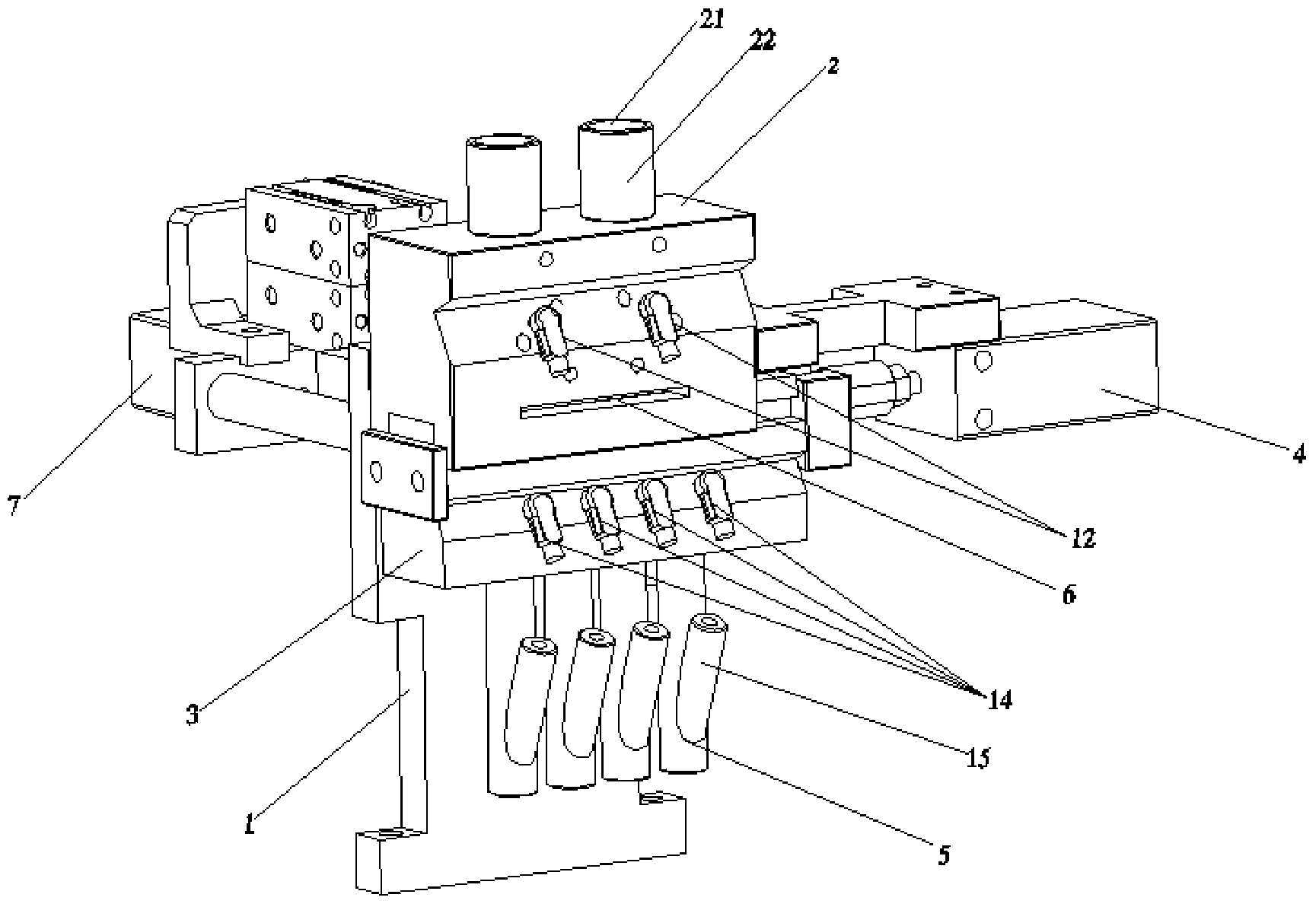

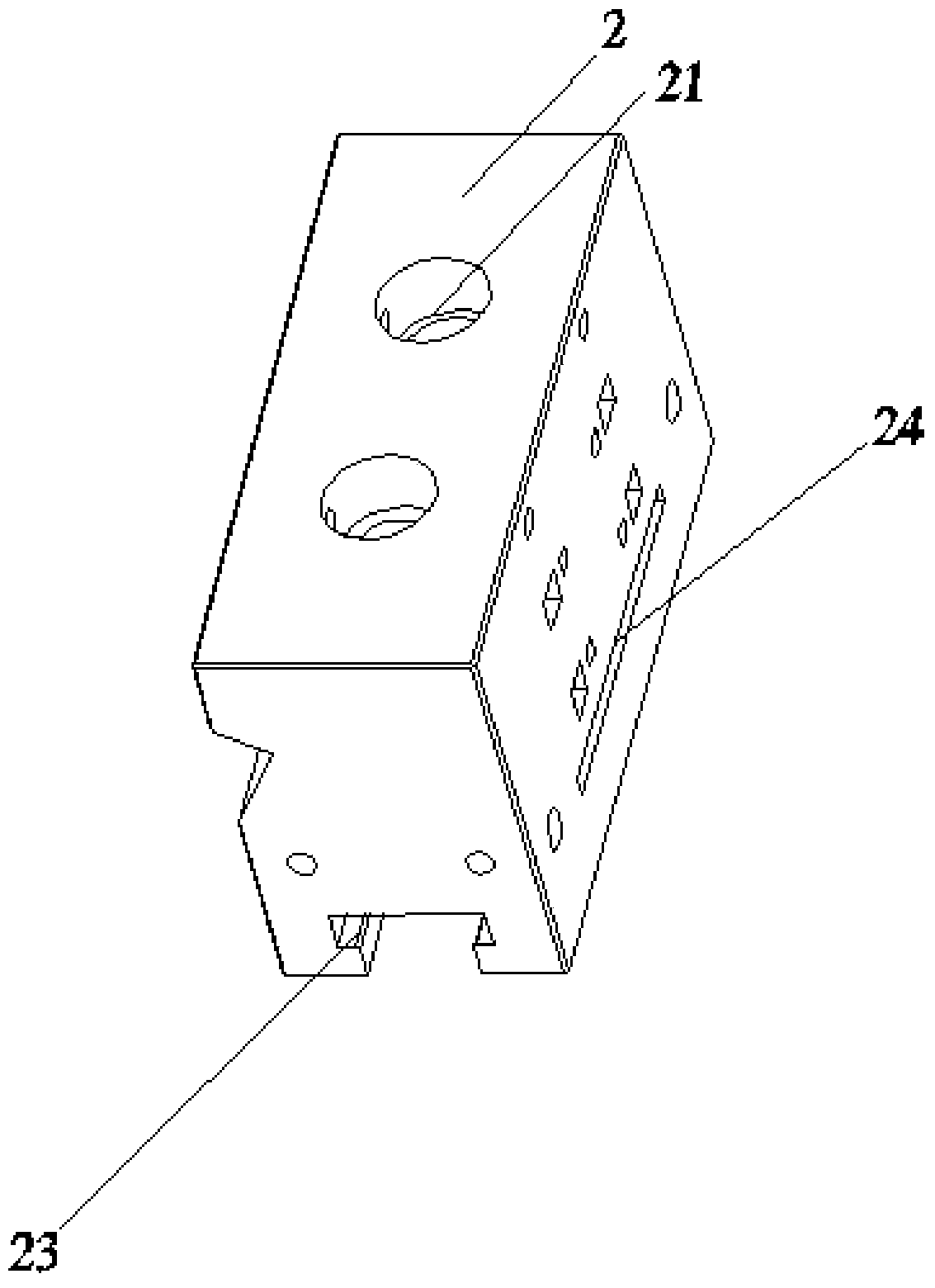

[0029] Such as Figure 1-4 As shown, an automatic feeding mechanism includes a support frame 1 and a feed block 2 fixed on the support frame 1. At least two feed openings 21 are opened on the top of the feed block 2. The feed block 2 is provided with a feed rail 22 communicating with the feed port 21, the bottom of the feed block 2 is provided with a chute 23, and a slider 3 is provided below the feed block 2, the The slider 3 is movably clamped on the sliding groove 23, the slider 3 is provided with at least four through holes 31, the slider 3 is driven by the first air cylinder 4, and the slider 3 is provided below There is a discharging track 5 communicating with the through hole 31, a discharging block 6 is arranged below the feeding rail 22, and the discharging block 6 is driven by the second cylinder 7, and the discharging block 6 is above A correction mechanism 8 extending into the feed rail 5 is provided, the correction mechanism 8 is driven by a third cylinder 9, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com