High-lift device optimum design method taking motion locus into account

A technology of increasing the lift device and motion trajectory, which is applied in the field of transport aircraft, and can solve problems such as difficulty in obtaining a satisfactory take-off configuration, increasing the complexity and size of the motion mechanism, and increasing the size of the rectification device of the motion mechanism, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

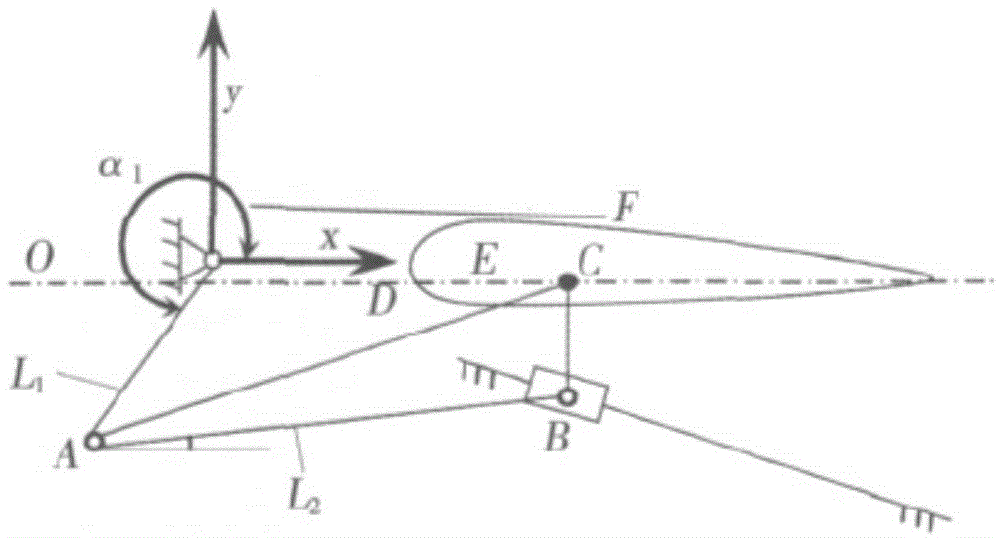

[0032] The present invention will be described in detail below in conjunction with the accompanying drawings.

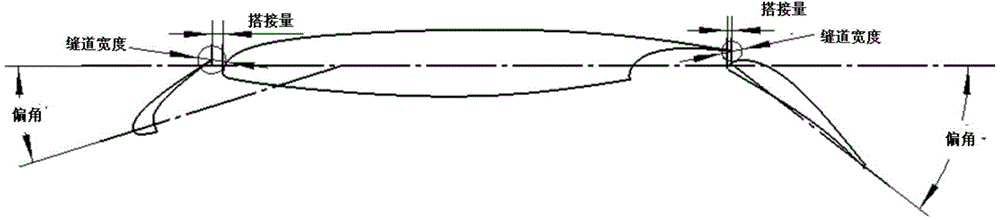

[0033] The high-lift device is composed of leading edge slats, main wing and trailing edge flaps, and is an important part of the wing. The trailing edge flap can be divided into single-slot flap and multi-slot flap. During take-off and landing, the slats and flaps of the wings deflect forward and backward respectively under the drive of the motion mechanism, which provides enough aerodynamic force for the aircraft. In the process of aerodynamic design of the high-lift device, the design of the two-dimensional high-lift device should be carried out firstly according to the two-dimensional airfoil profile of the wing.

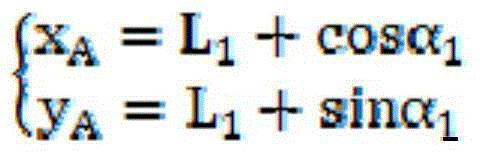

[0034] Step 1: Design the aerodynamic shape of the two-dimensional high-lift device on the basis of the two-dimensional airfoil;

[0035] The Bezier curve is used to design the surface shape of the high-lift device, and its expression is:

[0036] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com