A continuous swaging device and method for manufacturing molybdenum rod or molybdenum alloy rod

A technology of molybdenum alloy and molybdenum rods, applied in forging/pressing/hammer devices, manufacturing tools, operating devices, etc., can solve problems such as harsh environmental conditions, low production efficiency, and noise at the production site, and achieve improved environmental conditions at the production site, Prevention of serious oxidation problems and high processing dimensional accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

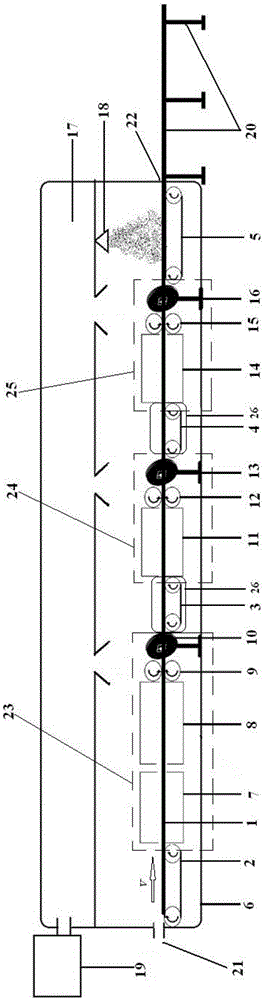

[0037] Comply with the above technical solutions, such as figure 1 As shown, this embodiment provides a continuous swaging device for manufacturing molybdenum rods or molybdenum alloy rods, including sequentially installed molybdenum or molybdenum alloy blanks 1 for conveying molybdenum or molybdenum alloy blanks 1 The first transmission mechanism 2, the second transmission mechanism 3, the third transmission mechanism 4 and the fourth transmission mechanism 5, the first transmission mechanism 2, the second transmission mechanism 3, the third transmission mechanism 4 and the fourth transmission mechanism 5 are all installed in the box body 6 capable of heat insulation and noise reduction, the molybdenum or molybdenum alloy billet 1 is fed from the feed port 21 of the box body 6, and the product molybdenum rod or molybdenum alloy rod obtained by continuous swaging is fed from the box body 6 The discharge port 22 sends out;

[0038] The top in the box body 6 is equipped with an...

Embodiment 2

[0057] The continuous swaging device of this embodiment is the same as that of Embodiment 1, and the setting and adjustment methods of each component are also the same, the difference is that the blank 1 of molybdenum or molybdenum alloy in this embodiment has a diameter of 15 mm to 19 mm. Molybdenum rod blanks.

[0058] Open the hydrogen atmosphere furnace 7, 8, 11 and 14 of the first to the fourth pass, adjust the hydrogen atmosphere furnace furnace temperature, the first hydrogen atmosphere furnace 7 furnace temperature is set to 900 ° C, the second hydrogen atmosphere furnace 8 furnace temperature is set Be set as 1250 ℃, the temperature setting of the 3rd hydrogen atmosphere furnace 11 and the 4th hydrogen atmosphere furnace 14 is 1300 ℃, the blank 1 of molybdenum or molybdenum alloy in the first hydrogen atmosphere furnace 7 and the second hydrogen atmosphere furnace 8 total The holding time is 20 minutes, and the total holding time in the third hydrogen atmosphere furna...

Embodiment 3

[0061] The continuous swaging device of this embodiment is the same as that of Embodiment 1, and the setting and adjustment methods of each component are also the same, the difference is that the blank 1 of molybdenum or molybdenum alloy in this embodiment is a molybdenum rod blank with a diameter of 12 mm to 15 mm.

[0062] Open the hydrogen atmosphere furnace 7, 8, 11 and 14 of the first to the fourth pass, adjust the hydrogen atmosphere furnace furnace temperature, the first hydrogen atmosphere furnace 7 furnace temperature is set to 850 ° C, the second hydrogen atmosphere furnace 8 furnace temperature is set Be set as 1250 ℃, the temperature setting of the 3rd hydrogen atmosphere furnace 11 and the 4th hydrogen atmosphere furnace 14 is 1300 ℃, the blank 1 of molybdenum or molybdenum alloy in the first hydrogen atmosphere furnace 7 and the second hydrogen atmosphere furnace 8 total The holding time is 15 minutes, and the total holding time in the third hydrogen atmosphere fu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com