Method for preparing supported type photocatalyst by ionic imprinting method

An ion imprinting method, photocatalyst technology, applied in chemical instruments and methods, physical/chemical process catalysts, organic compounds/hydrides/coordination complex catalysts, etc., can solve problems such as loading uniformity and reusable impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

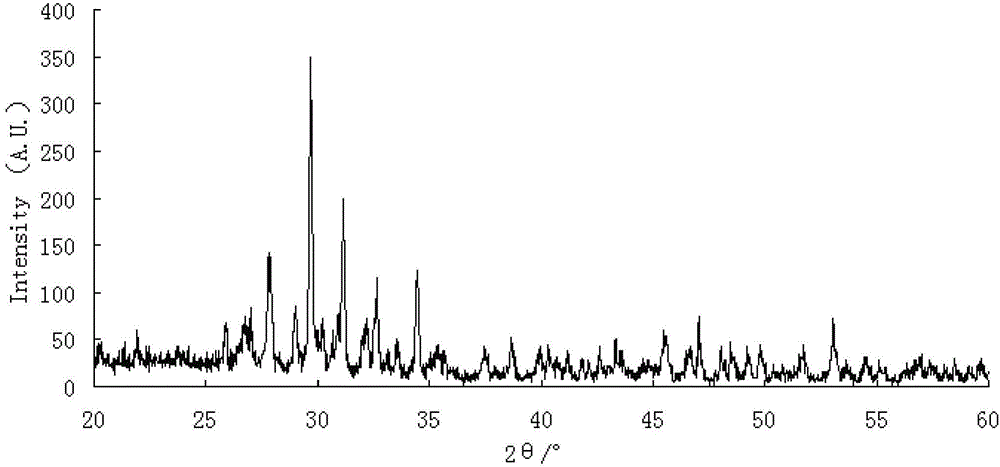

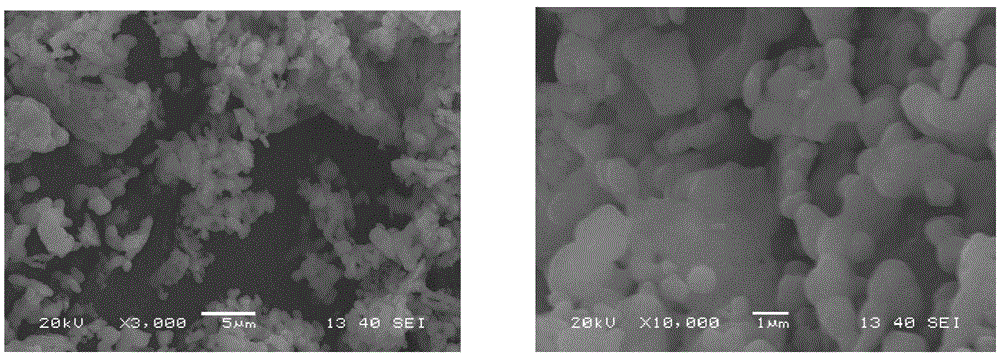

[0024] The present invention will be further described below in conjunction with the accompanying drawings.

[0025] A kind of ion imprinting method prepares the preparation method of supported photocatalyst, is characterized in that carrying out according to following steps: (1) preparation of hydroxyapatite powder: take by weighing 11.80g calcium nitrate and be dissolved in the beaker that a certain amount of deionized water is housed , add 3.4588g of phosphoric acid and place it on a magnetic stirrer to stir vigorously, stir at room temperature for 2 hours, and continuously add dilute ammonia water to control the pH value to 10; after the stirring is completed, let it stand and age for 24 hours, then use Buchner funnel to suction filter, Wash with absolute ethanol, dry at 100°C, place the dried product in a muffle furnace at 900°C for 2 hours and heat it for 1 hour, then cool to room temperature, take it out, and grind it to obtain hydroxyapatite powder. (2) Preparation of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com