Method for production of layered substrates

A substrate, direction of travel technology, used in devices, coatings, household components, etc. that apply liquid to the surface, can solve problems such as NIR spectral errors, achieve high predictability, high accuracy and reliability, reduce overfitting Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

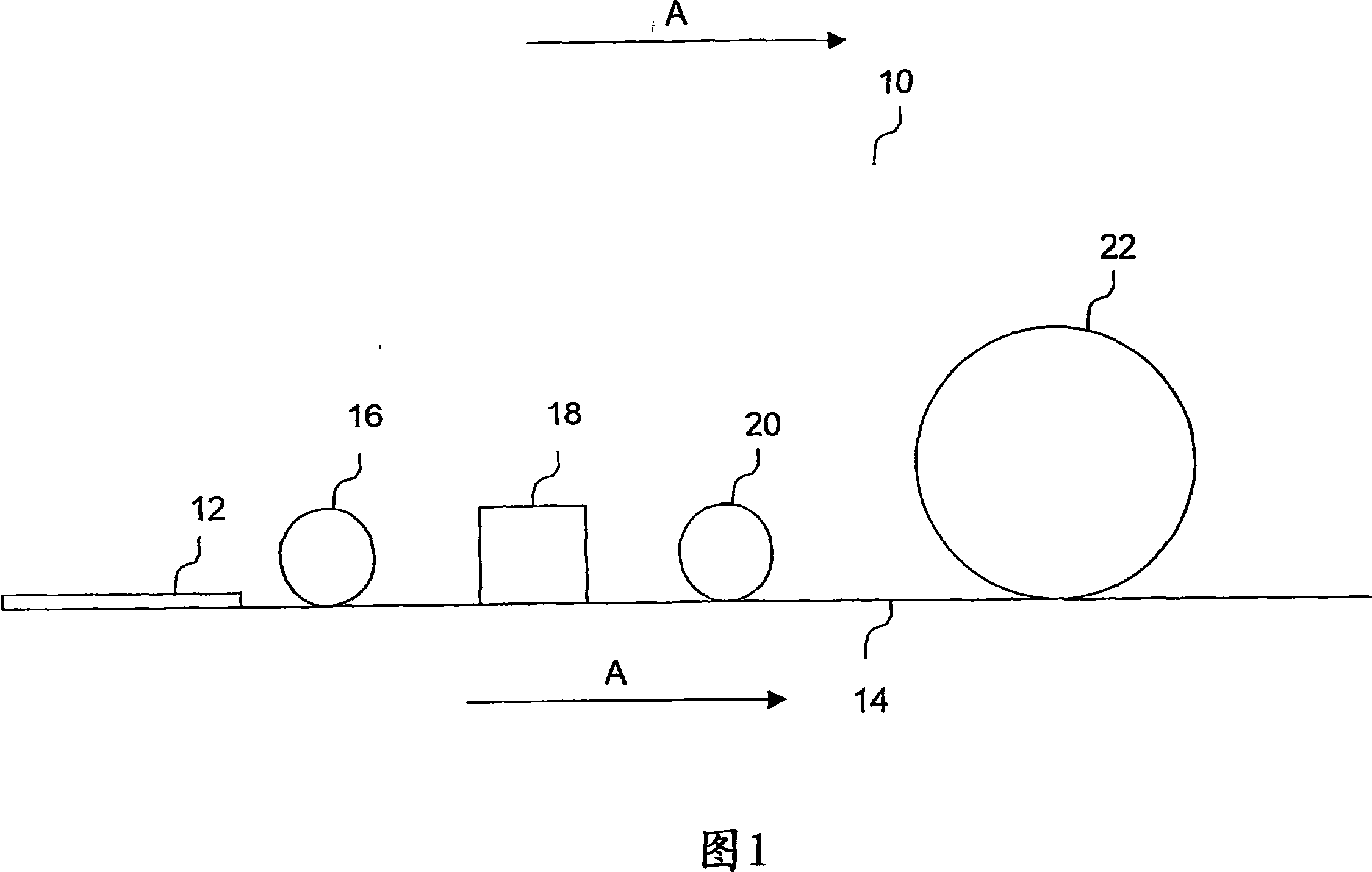

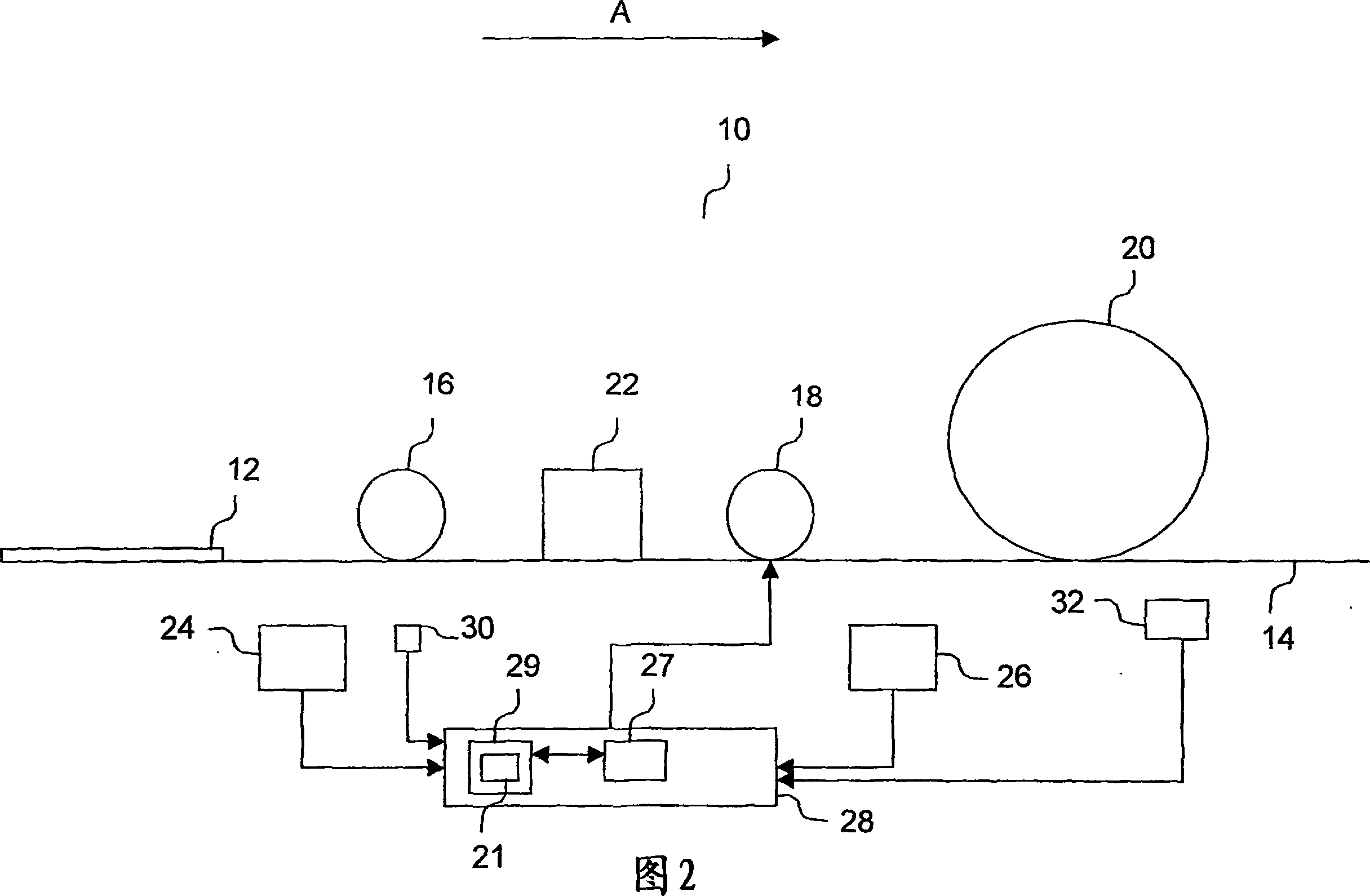

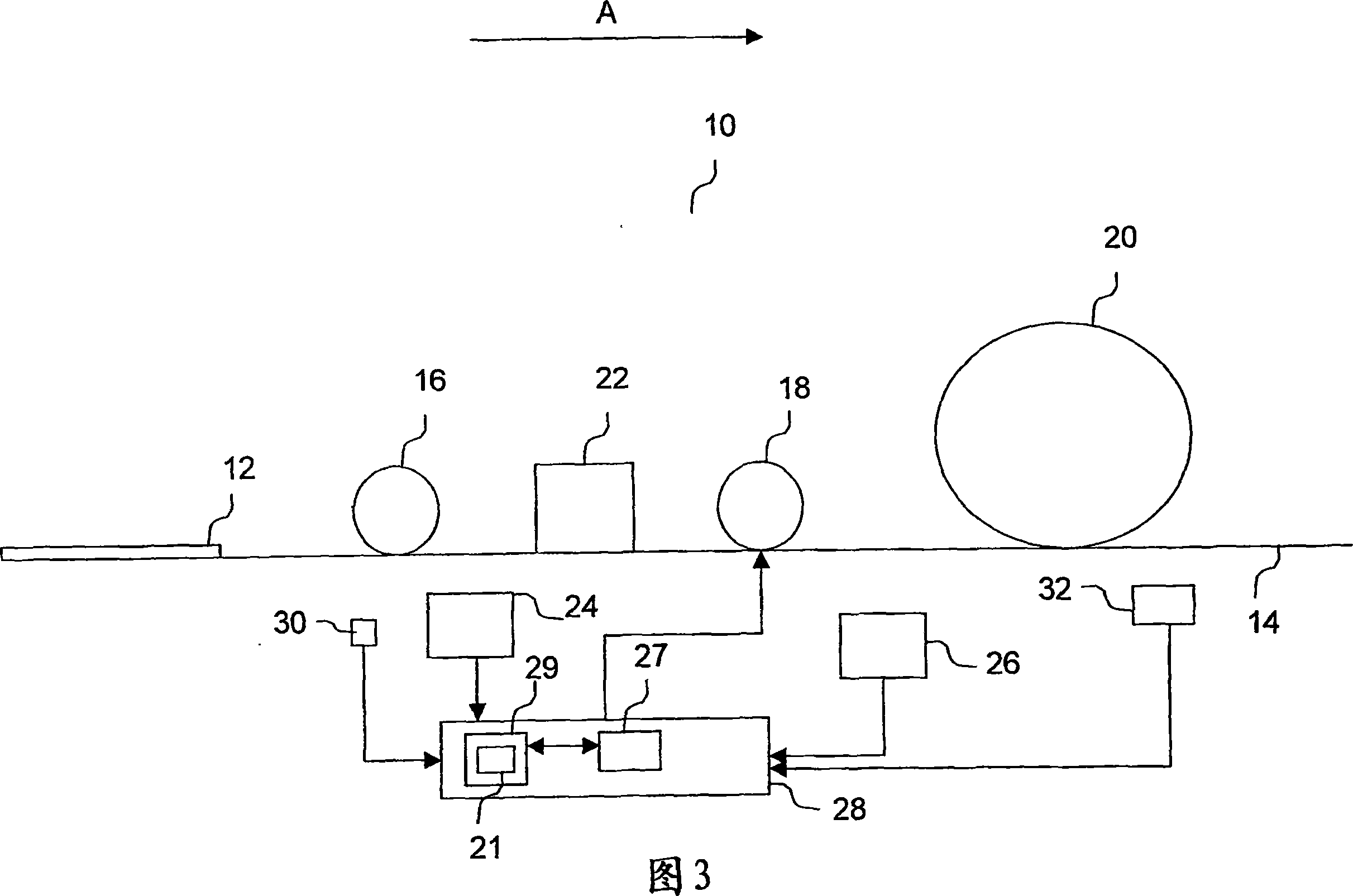

[0035] Referring first to Figure 1, a production line for producing layered substrates in which the system and method according to the present invention may be used will be described.

[0036] The production line 10 comprises: means for applying a hardener 16 adapted to apply the hardener to the substrate 12, such as a coater; means for applying the resin 18 to the substrate, such as a resin coater; and extrusion means 20, For example a hot rolling mill adapted to apply at least one layer to the substrate to form a layered substrate. However, a person skilled in the art will recognize that the layer can be applied to the substrate by means of, for example, planking, veneering or foiling. For example, the layer may be paper, veneer or fabric. In addition, it should be noted that there are many other suitable extrusion devices besides hot rolling mills, which may include plane pressing machines or cold presses, however plane pressing machines are not suitable in the case of foi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com