Magnetic carriers for electrophotographic developer, processes for producing same, and two-component developer

A magnetic carrier, electrophotography technology, applied in the direction of developer, electrography, optics, etc., can solve the problems of carrier chargeability degradation, image disorder carrier, toner consumption, etc., and achieve the suppression of carrier adhesion and magnetization value The effect of small deviation and excellent durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0137] The preparation of aqueous solution of methylol melamine is by adding melamine and aldehydes in water, while stirring, the reaction solution is heated up to a temperature range of 40 to 80° C., and the hydroxymethyl melamine solution is carried out at this temperature for 30 to 240 minutes, preferably 60 to 180 minutes. produced by methylation reactions.

[0138] At this time, it is desirable to slowly react the methylolation of melamine. The heating rate is preferably 0.5-1.5° C. / min, and the stirring rate is preferably 100-1000 rpm.

[0139] As the acid catalyst used in the present invention, a weak acid having an acid dissociation constant pKa of 3 to 6 can be suitably used, for example, formic acid, oxalic acid, acetic acid, etc. can be used, but acetic acid is most preferable. The content of the acid in the aqueous medium for forming composite particles is preferably 0.5 to 3% by weight.

[0140] The present invention is characterized in that an acidic aqueous so...

Embodiment 1

[0261] 〔Manufacture of spherical composite core particle〕

[0262]

[0263] Put the above material into a flask, stir at a stirring speed of 250rpm, raise the temperature to 85°C for 60 minutes, and react at this temperature for 120 minutes to solidify it, thereby carrying out the process of containing ferromagnetic iron oxide particles and binder resin. Generation of composite core particles.

[0264] Next, after cooling the contents in the flask to 30° C., the supernatant was removed, and the lower layer of the precipitate was washed with water and air-dried. Next, this was subjected to a heat treatment at 210° C. for 4 hours under a reduced pressure of 60 kPa under a nitrogen atmosphere, whereby spherical composite core particles 1 were obtained.

[0265] The spherical composite core particles 1 obtained here had an average particle diameter of 54 μm and a bulk density of 1.82 g / cm 3 , the specific gravity is 3.56g / cm 3 , the saturation magnetization value is 74.0Am ...

Embodiment 2~6、 comparative example 1~3

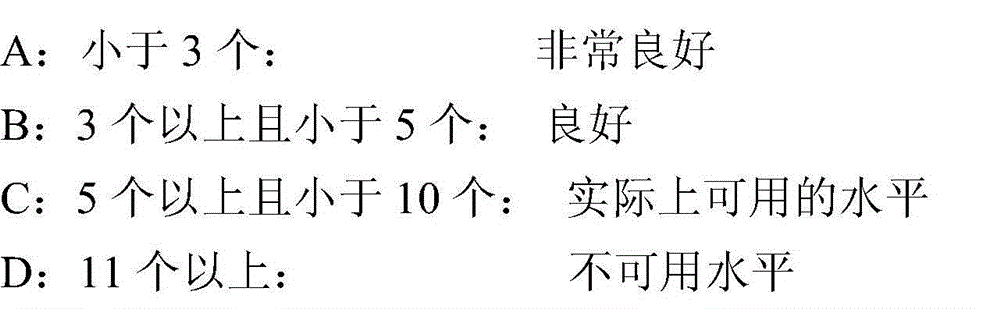

[0267] The spherical composite core particles 2 to 9 were obtained under the same conditions as the spherical composite core particle 1 except that the production conditions of the spherical composite core particles were variously changed. Table 2 shows the specifications of the obtained spherical composite core particles.

[0268] Table 3 shows various characteristics of the obtained spherical composite core particles 2 to 9.

[0269] [Table 2]

[0270]

[0271] [table 3]

[0272]

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com