Device with elements which can be moved relative to one another, preferably a planetary drive

A technology of relative motion and components, applied in the direction of gear transmission, transmission, transmission parts, etc., can solve problems such as energy loss, and achieve the effect of improving retention capacity and stable connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

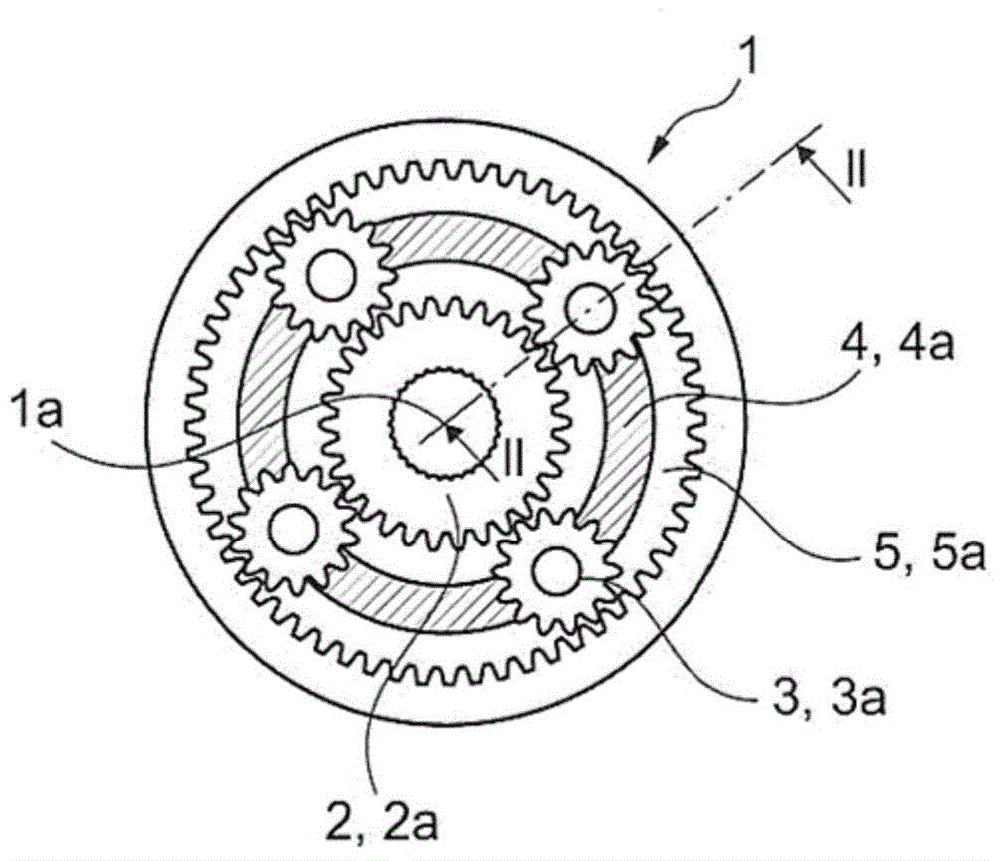

[0058] figure 1 A device 1 in the form of a planetary gear 1 a with relatively movable elements 2 , 3 , 4 and 5 is shown in side view and not to scale. Element 2 is the sun gear 2a and element 3 (first element 3 ) is a planetary gear 3a which is in toothed engagement with the sun gear 2a. The element 5 is the ring gear 5a with which the planet gears 3a are in tooth engagement. The element 4 (third element 4) is the planet carrier 4a.

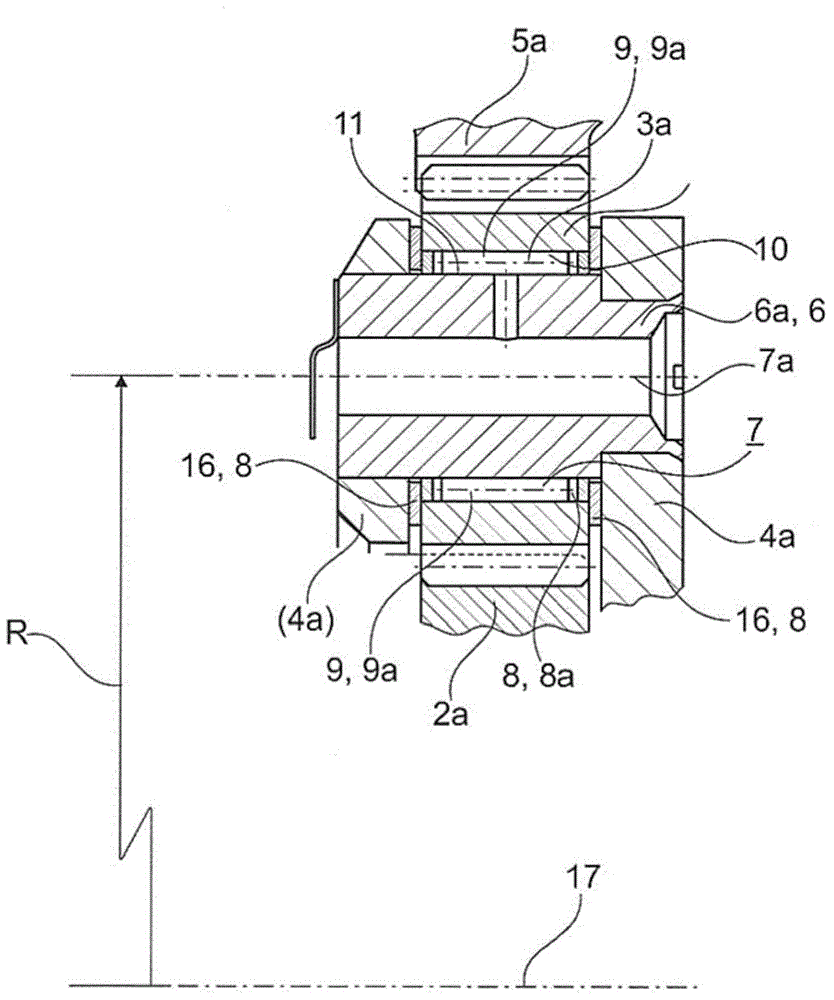

[0059] figure 2 along the basis figure 1 The line II-II shows a cross-sectional view of the details of the device. For each planet gear 3a, a further element 6 (second element 6), which is formed as a planet pin 6a, is fastened to the planet carrier 4a. Each planet gear 3 a is mounted rotatably about an axis of rotation 7 a on a planet pin 6 a (on the second element 6 ) by means of a rolling bearing 7 . Each planetary gear 3a is in toothed engagement with the ring gear 5a and with the sun gear 2a. The axis of rotation 7 a is spaced at ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com