Heat dissipation module of circuit board

A heat dissipation module and circuit board technology, applied in the direction of circuit heating devices, circuits, printed circuits, etc., can solve the problems of easy generation of test noise, high noise, and inability to dissipate heat in time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

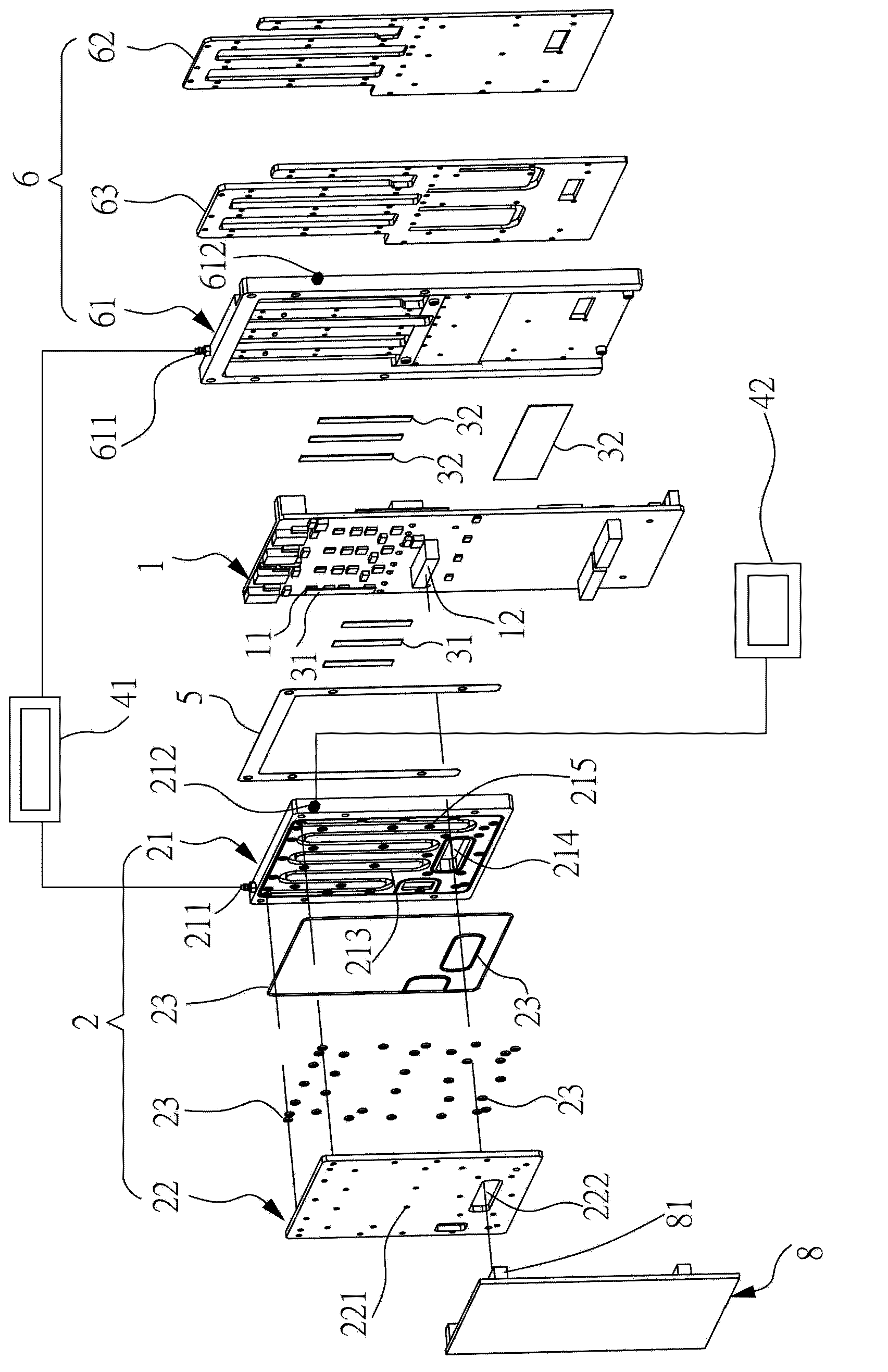

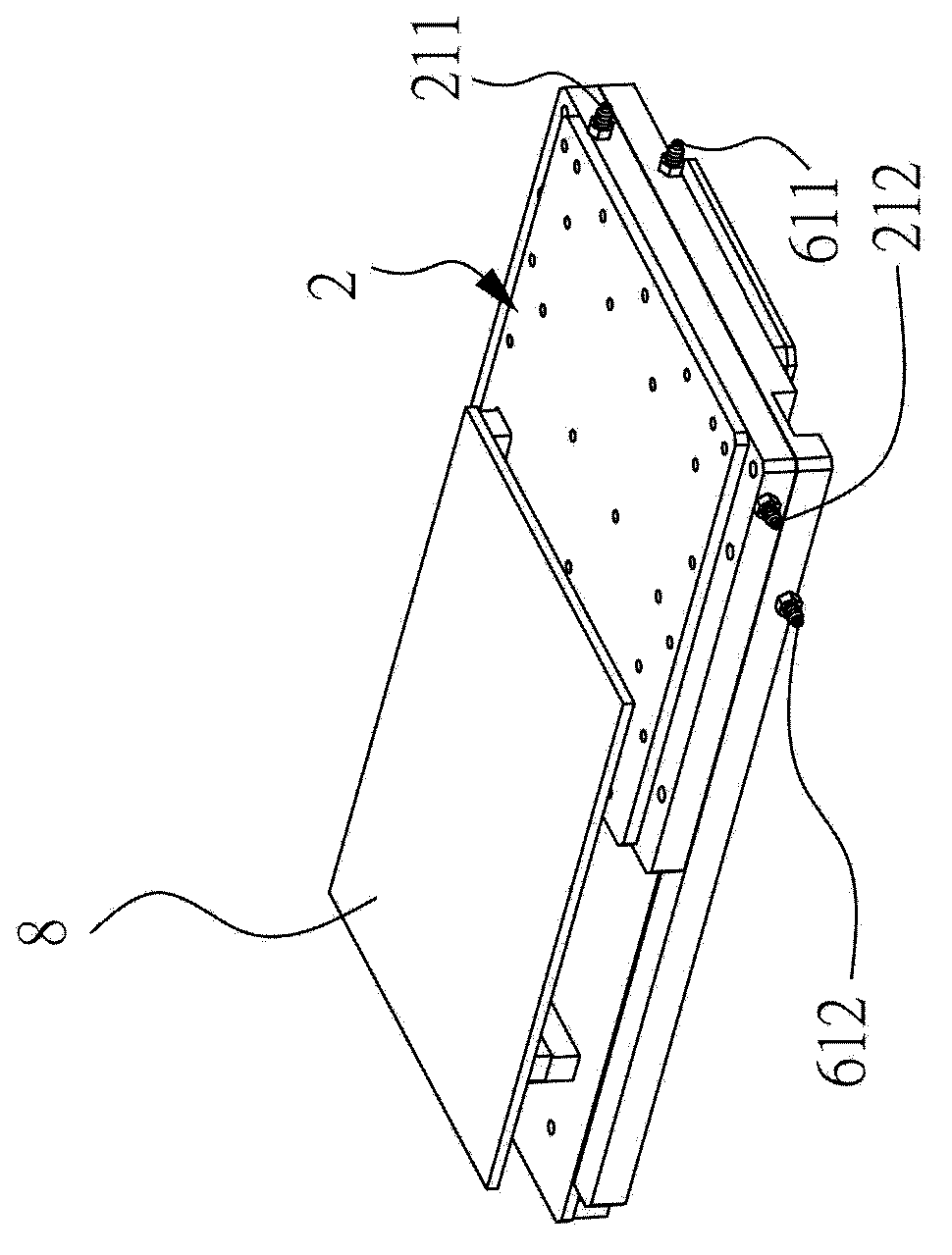

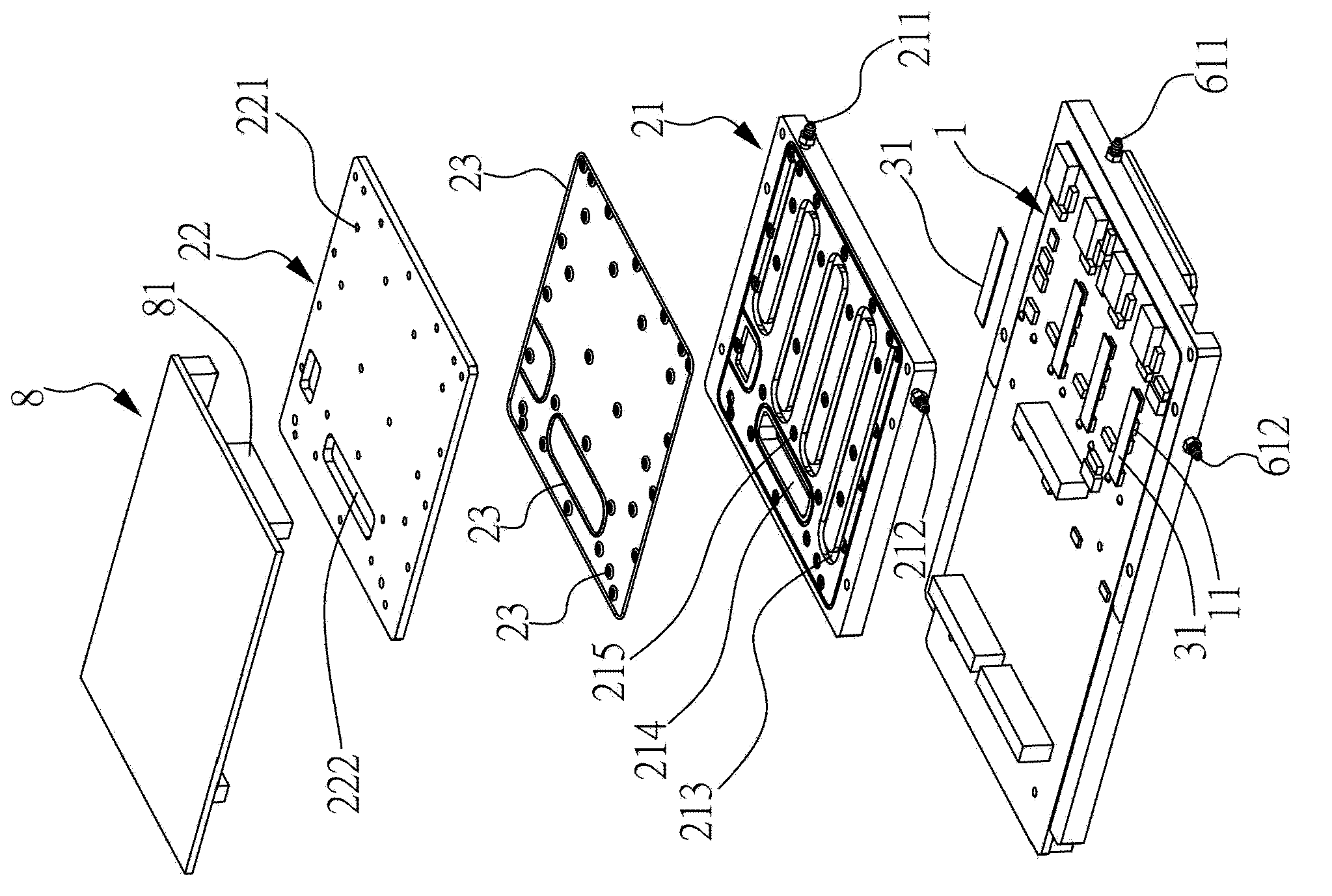

[0040] Such as figure 1 , figure 2 as well as image 3 Shown are the front exploded view, front perspective view and partial exploded view of the upper side of the main circuit board of the first preferred embodiment of the circuit board cooling module of the present invention. As shown in the figure, a circuit board cooling module in this embodiment includes: a main circuit board 1, a first heat sink 2, a plurality of heat conducting fins 31, 32, an air pump 41, a muffler 42, a An insulating gasket 5 and a second heat sink 6 .

[0041] The first heat sink 2 is disposed on the upper side of the main circuit board 1 , and includes: a first heat sink body 21 , a first heat sink cover 22 and a plurality of seals 23 . The first heat sink body 21 has an air intake hole 211 , an exhaust hole 212 and an air channel 213 communicating with the air intake hole 211 and the exhaust hole 212 . The first heat dissipation cover 22 includes a plurality of openings 221 , and the first hea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com