Tread pattern groove pumping noise source recognition method

A tire pattern and sound source recognition technology, which is applied in the direction of automobile tire testing, special data processing applications, instruments, etc., can solve the problem of not being able to clearly indicate the location of the noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

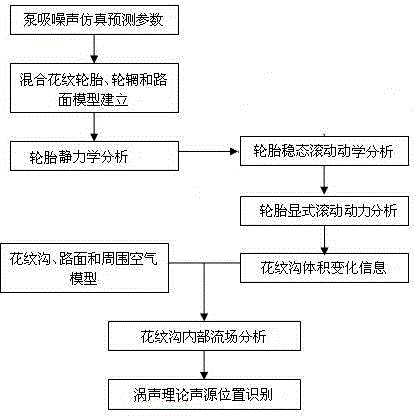

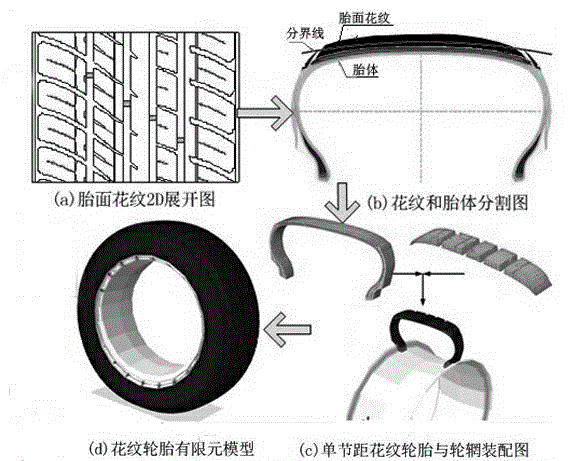

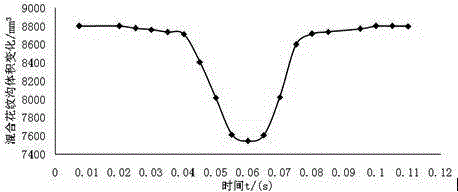

[0069] Embodiment: The present invention takes the pattern structure of 205 / 55R16 tire Steering Ace AU01 as an example, as figure 1 , figure 2 and image 3 As shown, the flow chart of the identification method of groove noise sound source based on CFD dynamic mesh technology. Firstly, the finite element model of the tire with mixed pattern is established, and the static load analysis of the tire is carried out to obtain the static mechanical analysis of the tire, and then the steady-state rolling of the tire is realized by the ALE method, and then the steady-state calculation result file is converted as the transient calculation The initial state calculates the transient rolling, and obtains the change information of the groove volume over time under the dynamic force of the tire. Finally, the volume change of the groove in the docking area is applied as the boundary condition to realize the velocity and turbulent kinetic energy flow in the process of air pumping inside the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com