Method for preparing 2,2,4-trimethyl-1,3-pentanediol diisobutyrate

A technology of pentanediol diisobutyrate and trimethyl is applied in the preparation of carboxylate, chemical instruments and methods, preparation of organic compounds, etc., and can solve the problems of high production cost, expensive monoisobutyrate and the like , to achieve the effect of simple operation and avoiding the need for a large amount of lye to neutralize the product

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

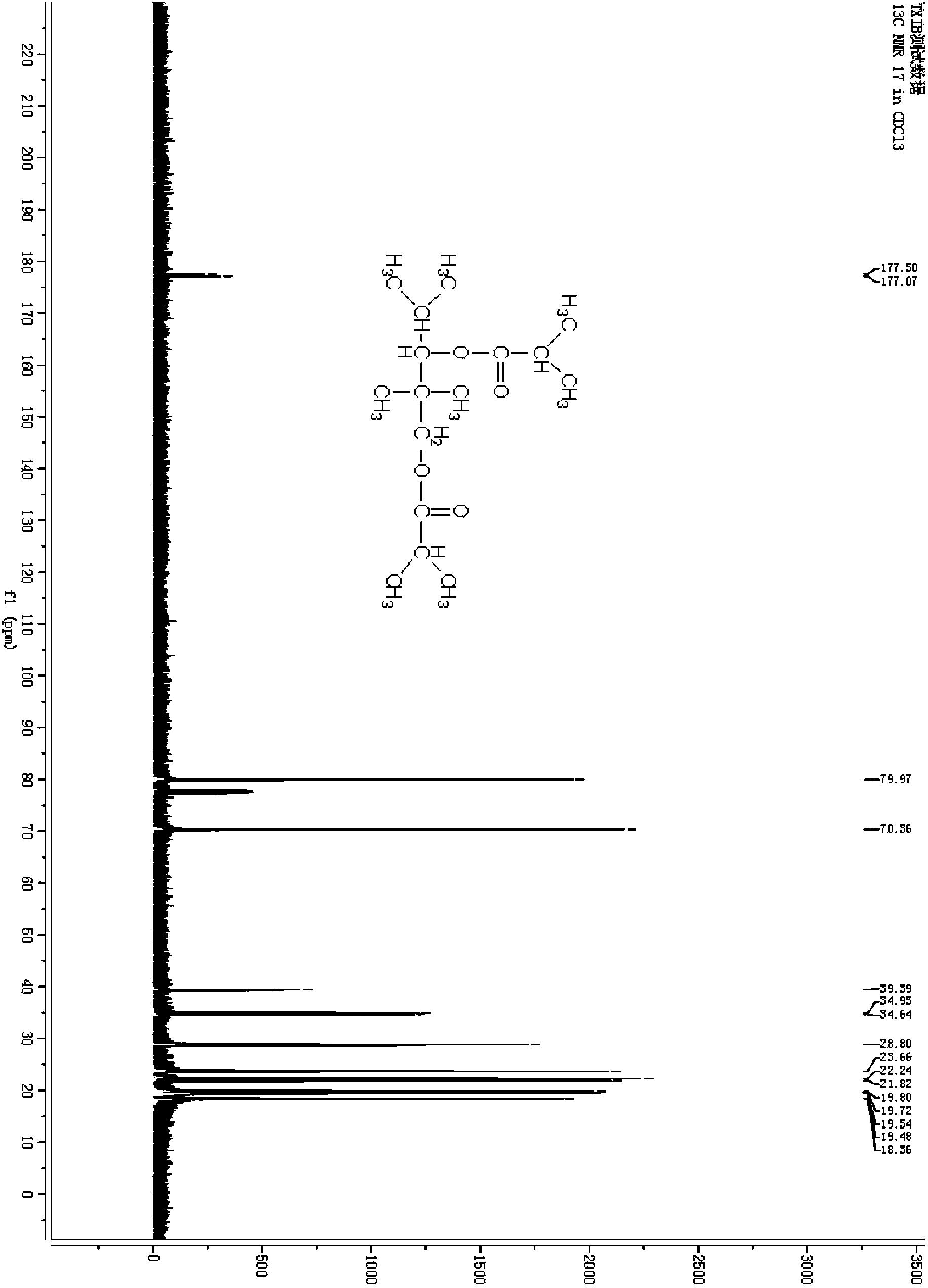

Image

Examples

Embodiment 1

[0022] a. Bubble the gas purging device with stirring, reflux condenser, water separator and sieve plate (the structure of the gas purging device is a two-way with a gas regulating valve: one end has a sand core sieve plate, extending The gas can be blown out evenly under the liquid surface; the other end is connected to the reactor with a gas flow meter), and 40 g of green leaf oxane (2,4-diisopropyl-5,5-dimethyl-1,3 -dioxane), add 0.6g PW 12 (12-phosphotungstic acid) / SiO 2 (weight 40wt%) load heteropoly acid, slowly add 42g isobutyric acid dropwise with stirring, and carry out the reaction at 150°C; the reaction time is 7h;

[0023] b. The interval is 1 to 2 hours. When small water droplets appear on the surface of the water separator, adjust the flow rate of the gas flow meter of the gas purging device to 12L / h, and control the gas flow rate to separate the isobutyraldehyde and water generated in the reaction;

[0024] c, after the reaction finishes, adjust the gas flow r...

Embodiment 2

[0027] a. Bubble the gas purging device with stirring, reflux condenser, water separator and sieve plate (the structure of the gas purging device is a two-way with a gas regulating valve: one end has a sand core sieve plate, extending The gas can be blown out evenly under the liquid surface; the other end is connected to the reactor with a gas flow meter), and 20g of green leaf oxane (2,4-diisopropyl-5,5-dimethyl-1,3 -dioxane), add 0.3g copper p-toluenesulfonate, slowly add 28g isobutyric acid dropwise with stirring, and carry out the reaction at 150°C; the reaction time is 7h;

[0028] b. The interval is 1 to 2 hours. When small water droplets appear on the surface of the water separator, adjust the flow rate of the gas flow meter of the gas purging device to 12L / h, and control the gas flow rate to separate the isobutyraldehyde and water generated in the reaction;

[0029] c, after the reaction finishes, adjust the gas flow rate of the gas purging device to be 24L / h, control ...

Embodiment 3-10

[0032] a. Bubble the gas purging device with stirring, reflux condenser, water separator and sieve plate (the structure of the gas purging device is a two-way with a gas regulating valve: one end has a sand core sieve plate, extending The gas can be blown out evenly under the liquid surface; the other end is connected to the reactor with a gas flow meter), and an appropriate amount of aoba oxane (2,4-diisopropyl-5,5-dimethyl-1,3 -dioxane) and p-toluenesulfonic acid, slowly add an appropriate amount of isobutyric acid dropwise with stirring, and carry out the reaction at 150-160 °C; the reaction time is 6-9h;

[0033] b. The interval time is 1min to 4h. When small water droplets appear on the surface of the water separator, adjust the flow rate of the gas flow meter of the gas purging device to 12L / h, and control the gas flow rate to separate the isobutyraldehyde and water generated in the reaction;

[0034] c, after the reaction finishes, adjust the gas flow rate of the gas pu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com