Method for producing organic fertilizer from kitchen waste

A technology of food waste and organic fertilizer, applied in the direction of organic fertilizer, climate change adaptation, etc., to achieve the effect of simple operation, reduced transportation and treatment costs, and thorough treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

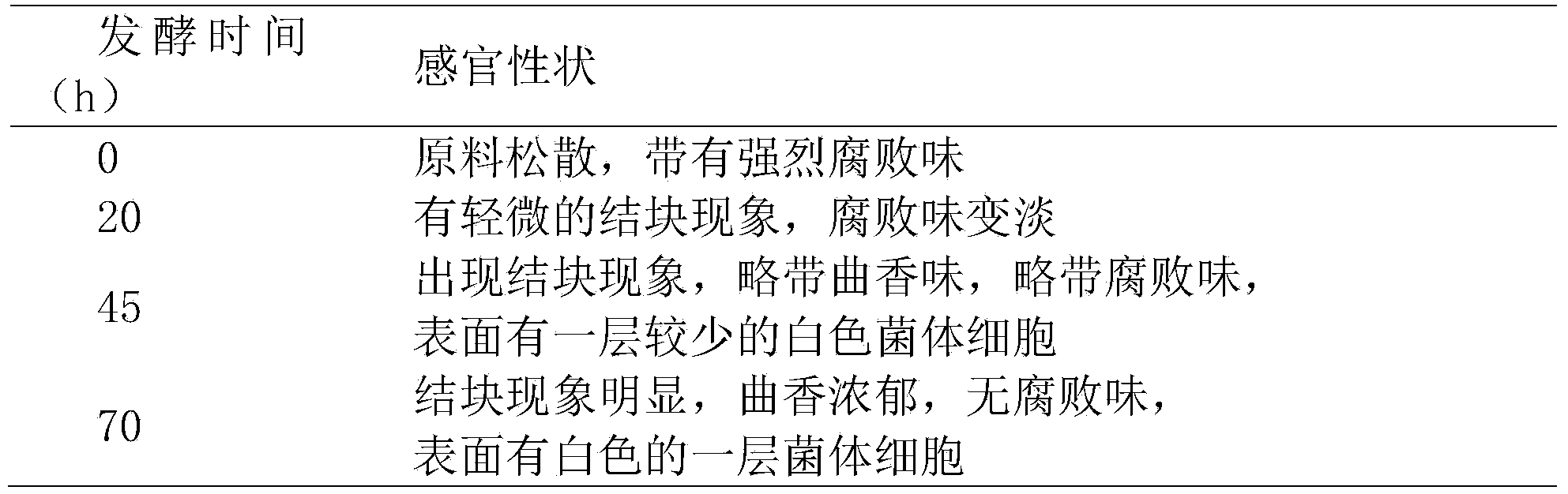

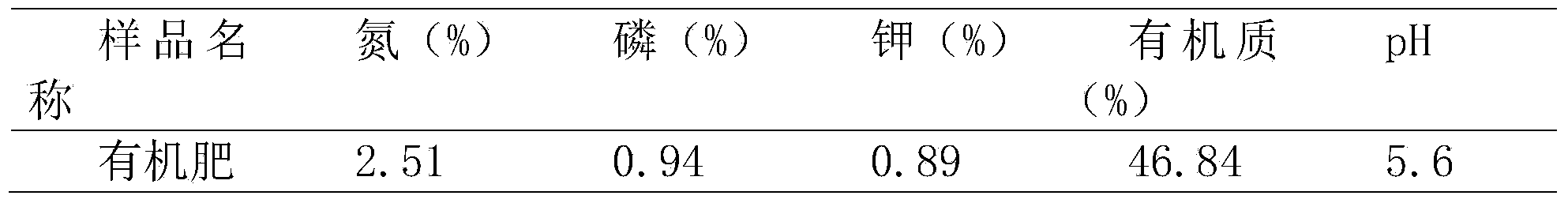

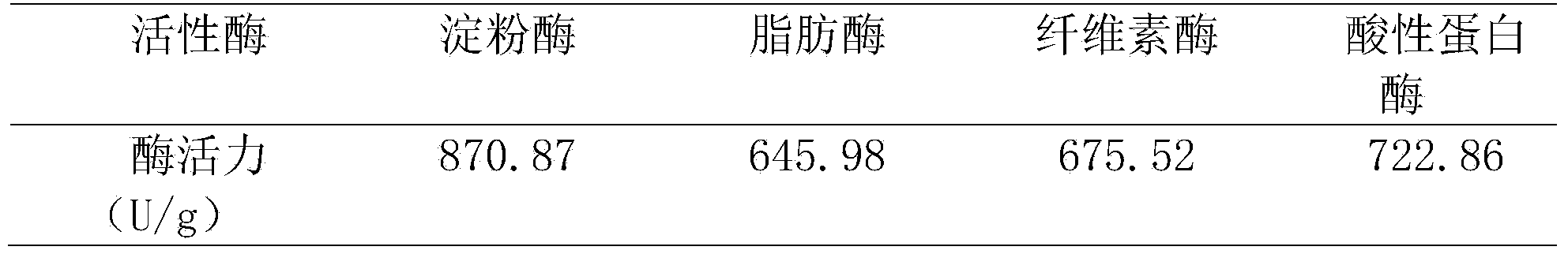

Embodiment 1

[0022] 500g of kitchen waste is packed into a porcelain plate, wherein about 10% of bran is added to adjust the water content of the material to 55%. Bacillus amyloliquefaciens, Bacillus cereus, Candida lipolytica and Candida tropicalis were selected as fermentation strains. Utilize beef extract 2g, peptone 5g, NaCl 3g, agar 2g, water 500mL, prepare Bacillus amyloliquefaciens and Bacillus cereus slant medium; Utilize yeast powder 3g, peptone 8g, glucose 15g, agar 2g, water 500mL, prepare solution Candida liposum and Candida tropicalis slants. Take fresh slant culture medium, transfer Bacillus amyloliquefaciens, Bacillus cereus, Candida lipolytica and Candida tropicalis into fresh slant medium respectively, put Bacillus amyloliquefaciens and Bacillus cereus at 35°C After culturing for 22 hours, Candida lipolytica and Candida tropicalis were cultured at 30° C. for 22 hours to obtain four activated strains. Then the activated strains were respectively transferred to the seed cu...

Embodiment 2

[0037]500g of kitchen waste is packed into a porcelain plate, wherein about 10% of bran is added to adjust the water content of the material to 57%. Bacillus amyloliquefaciens, Bacillus cereus, Candida lipolytica and Candida tropicalis were selected as fermentation strains. Utilize beef extract 3g, peptone 10g, NaCl 5g, agar 2.5g, water 1000mL, prepare Bacillus amyloliquefaciens and Bacillus cereus slant culture medium; Utilize yeast powder 5g, peptone 10g, glucose 20g, agar 2.5g, water 1000mL, Prepare Candida lipolytica and Candida tropicalis slants. Take fresh slant culture medium, transfer Bacillus amyloliquefaciens, Bacillus cereus, Candida lipolytica and Candida tropicalis into fresh slant medium respectively, put Bacillus amyloliquefaciens and Bacillus cereus at 37°C Cultivate Candida lipolytica and Candida tropicalis at 32° C. for 24 hours to obtain four activated strains. Then the activated strains were transferred into the seed medium respectively, and Bacillus amyl...

Embodiment 3

[0053] 500g of kitchen waste is packed into a porcelain plate, wherein about 10% of bran is added to adjust the water content of the material to 60%. Bacillus amyloliquefaciens, Bacillus cereus, Candida lipolytica and Candida tropicalis were selected as fermentation strains. Utilize beef extract 5g, peptone 15g, NaCl 8g, agar 3g, water 1500mL, prepare Bacillus amyloliquefaciens and Bacillus cereus slant medium; Utilize yeast powder 7g, peptone 12g, glucose 25g, agar 3g, water 1500mL, prepare solution Candida liposum and Candida tropicalis slants. Take fresh slant culture medium, transfer Bacillus amyloliquefaciens, Bacillus cereus, Candida lipolytica and Candida tropicalis into fresh slant medium respectively, put Bacillus amyloliquefaciens and Bacillus cereus at 39°C Cultivate Candida lipolytica and Candida tropicalis at 34° C. for 26 hours to obtain four activated strains. Then the activated strains were transferred into the seed medium respectively, and Bacillus amyloliqu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com