A silicon carbide-based composite material absorbing microwave heating element composition and its preparation method

A composite material and microwave-absorbing technology, which is applied in the field of composite materials, can solve problems such as easy oxidation of joints, difficulty in forming a special atmosphere, heat generation shape, and lack of flexibility in installation, so as to achieve the effect of improving mechanical properties and microwave absorption performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] In this embodiment, the silicon carbide-based composite material absorbing microwave heating element composition is made of the following raw materials in mass fractions: 90 parts of main agent, 10 parts of modifier; 3 parts of additional binder, 7 parts of water; Silicon carbide powder with an average particle size of 95 μm, 7 parts of the modifying agent, a mixture of alumina powder with an average particle size of 40 μm and 3 parts of silica powder with an average particle size of 50 μm, and the binder is 3 parts of polyethylene Alcohol, the solvent is 7 parts of distilled water.

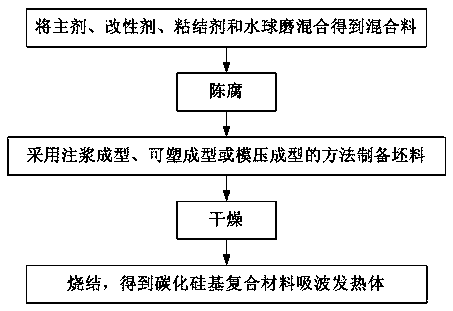

[0045] refer to figure 1 As shown, the preparation method of the silicon carbide-based composite material absorbing microwave heating element composition in this embodiment is carried out according to the following steps:

[0046] Step 1. Ball milling: Add the main agent, modifier, binder and water into the ball mill and mix them evenly to obtain the mixture;

[0047] Step 2, stale: heat...

Embodiment 2

[0053] In this embodiment, the silicon carbide-based composite material absorbing and heating element is made of the following mass fractions of raw materials: 85 parts of main agent, 15 parts of modifier; 5 parts of additional binder, 8 parts of water; the main agent is the average particle size 60 μm silicon carbide powder, the modifier is 9 parts, a mixture of alumina powder with an average particle size of 40 μm and 6 parts of titanium oxide powder with an average particle size of 35 μm, and the binder is 5 parts of hydroxymethyl cellulose, The solvent is 8 parts distilled water.

[0054] combine figure 1 , the preparation method of silicon carbide-based composite material wave-absorbing heating element in this embodiment:

[0055] Step 1. Ball milling: Add the main agent, modifier, binder and water together into the ball mill and mix evenly to obtain the mixture;

[0056] Step 2, stale: heat the mixture described in step 1 at 25°C for 40 hours for stale treatment;

[0...

Embodiment 3

[0062] The wave-absorbing and heating element of silicon carbide-based composite material in this embodiment is made of the following raw materials in mass fraction: 88 parts of main agent, 12 parts of modifier; 6 parts of additional binder, 28 parts of water; the main agent is the average particle size 100 μm silicon carbide powder, the modifier is a mixture of 7 parts of feldspar powder with an average particle size of 50 μm and 5 parts of silicon dioxide powder with an average particle size of 50 μm, the binder is carboxymethyl starch, and the solvent is distilled water.

[0063] combine figure 1 , the preparation method of silicon carbide-based composite material wave-absorbing heating element in this embodiment:

[0064] Step 1. Ball milling: Add the main agent, modifier, binder and water together into the ball mill and mix evenly to obtain the mixture;

[0065] Step 2, aging: the mixture described in step 1 is sealed and kept for 40 hours at a temperature of 25°C for ag...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| ignition point | aaaaa | aaaaa |

| ignition point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com