Forming technology for nose body of rifle

A forming process and machine head technology, which is applied in the field of rifle machine head body forming process, can solve the problems of high metal consumption by flash, high working noise, and large forging allowance, so as to improve surface quality, reduce noise, and forging allowance small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Embodiments of the present invention will be described in further detail below in conjunction with the accompanying drawings.

[0018] The forming process of the machine head body of the rifle of the present invention has the following process flow: blanking→heating→heading→extrusion forming→edge trimming. details as follows:

[0019] a, blanking: select round bar material;

[0020] b. Heating: heat the round bar to 1150°C~1250°C. When heating, only one end that needs to be pierced can be locally heated;

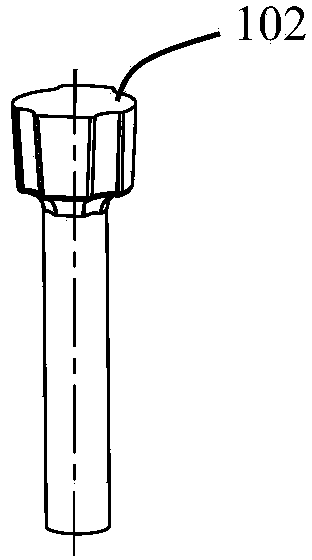

[0021] c. Upsetting: put the heated round bar on the electric heating upsetting machine to form a blank. The blank is as follows: figure 1 shown;

[0022] d. Extrusion forming: put the blank into the forming die for extrusion forming to form a forging. Forgings such as figure 2 As shown, among them, the upper mold and the lower mold of the forming mold are preheated to a temperature of 250°C to 300°C, the temperature of the blank is 1150°C to 1250°C, and the extr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com