Hybridized dendrimer-loaded bimetal metal nanoparticle catalyst as well as preparation method and application thereof

A technology of metal nanoparticles and dendrimers, applied in organic compound/hydride/coordination complex catalysts, physical/chemical process catalysts, chemical instruments and methods, etc., can solve the problem of low catalytic activity and difficulty in recycling catalysts, etc. problems, to achieve high selectivity, excellent catalytic hydrogenation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

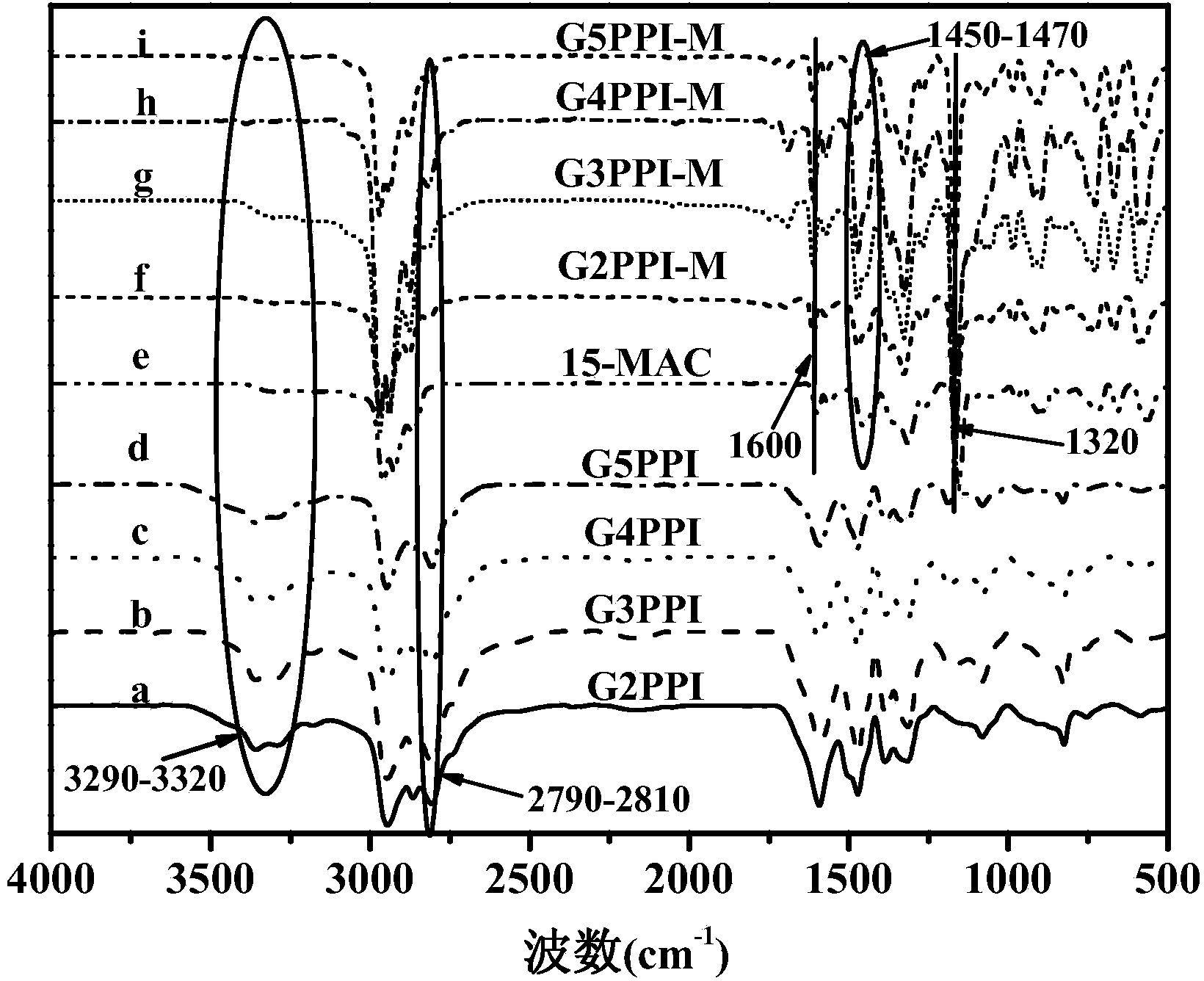

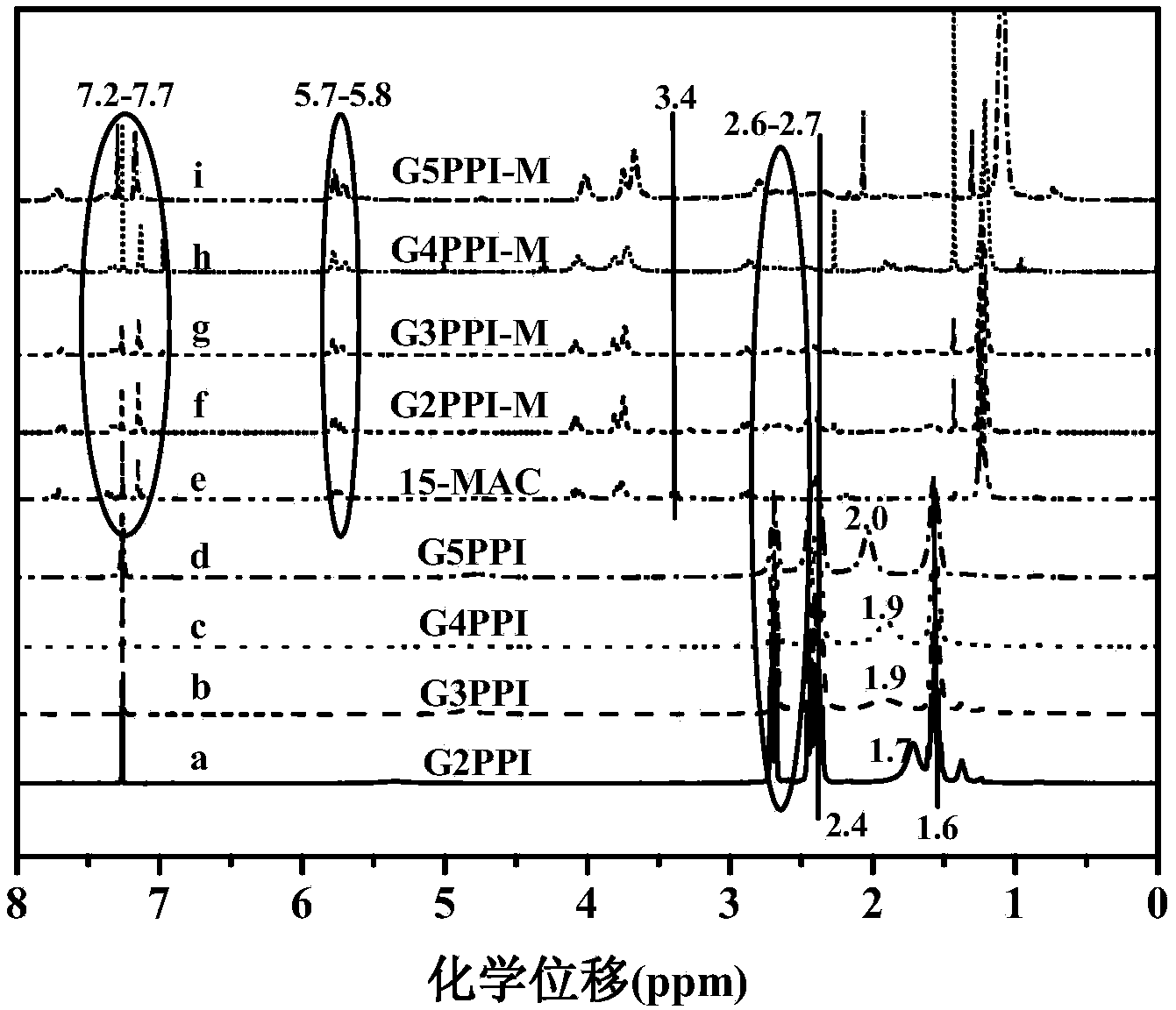

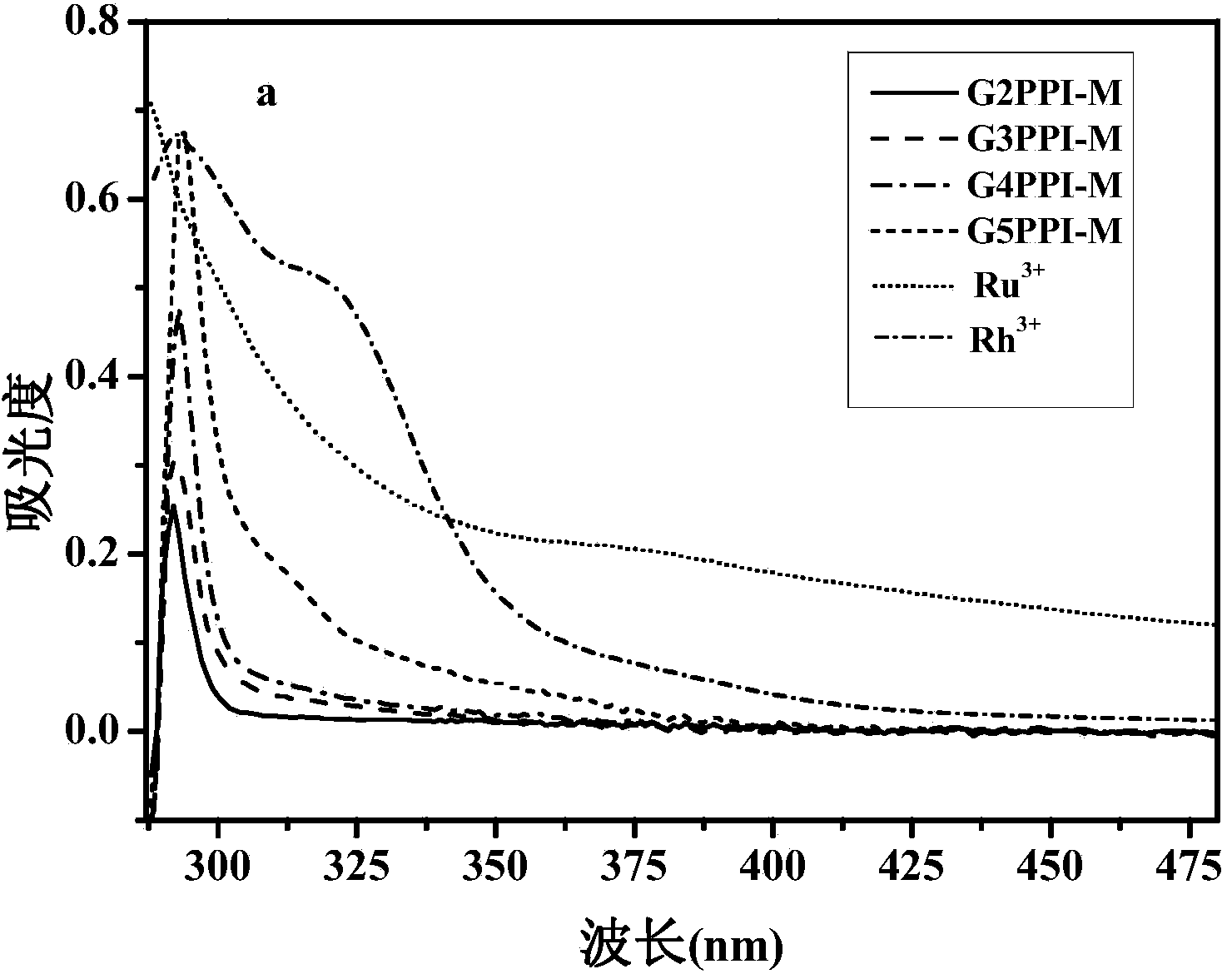

[0039] Example 1 Second-generation hybrid dendritic polymer-loaded bimetallic nanoparticles and its catalytic hydrogenation of nitrile rubber

[0040] 1. Surface-modified second-generation polypropyleneimine dendrimers (G 2 PPI-M) take 2.155g (2.79×10 ‐3 mol)G 2 PPI (Netherlands SyMO-Chem B.V company) was dissolved in 10ml acetonitrile for later use. 0.48g (4.8×10 ‐4 mol)1,11‐di[2,4,6‐triisopropylbenzenesulfonyl]‐6‐[4‐(3‐bromopropyl)benzenesulfonyl]‐1,6,11‐triazacyclodeca Pentadecane‐3,8,13‐triene (MAC), 0.33g (2.4×10 ‐3 mol) of anhydrous potassium carbonate is placed in a reaction flask with a reflux and ventilation device. Connect the external ventilation device and replace the N 2 three times. Under normal temperature stirring, inject 0.24mlG into the flask successively 2 PPI / acetonitrile solution and 30ml acetonitrile. The temperature was raised to 107°C for 12 hours. After the reaction was completed, the solid powder was removed by filtration, and the solid powd...

Embodiment 2

[0053] Example 2 The third generation of hybrid dendrimers loaded with bimetallic nanoparticles and its catalytic hydrogenation of nitrile rubber

[0054] 1. G 3 Synthesis of PPI‐M

[0055] Accurately weigh 1.610g (9.54×10 ‐4 mol)G 3 PPI (Netherlands SyMO-Chem B.V company) was dissolved in 10ml acetonitrile for later use. Take 0.80g (8.0×10 ‐4 mol) MAC, 0.56g (4.1×10 ‐3 mol) of anhydrous potassium carbonate is placed in a reaction flask with a reflux and ventilation device. Connect the external ventilation device and replace the N 2 three times. Under stirring at room temperature, inject 0.56mlG into the flask successively 3 PPI / acetonitrile solution, 30ml acetonitrile. Then the temperature was raised to 107°C for 18 hours. After the reaction was completed, the solid powder was filtered out, and the solid powder was washed three times with tetrahydrofuran during filtration to obtain a filtrate. The filtrate was distilled under reduced pressure to obtain an oily liqu...

Embodiment 3

[0068] Example 3 The fourth generation of hybrid dendrimers loaded with bimetallic nanoparticles and its catalytic hydrogenation of nitrile rubber

[0069] 1. G 4 Synthesis of PPI-M

[0070] Take 0.654g (1.86×10 ‐4 mol) G 4 PPI (Netherlands SyMO-Chem B.V company) was dissolved in 17ml acetonitrile for later use. 0.84g (8.4×10 ‐4 mol) MAC, 0.62g (4.5×10 ‐3mol) of anhydrous potassium carbonate is placed in a reaction flask with a reflux and ventilation device. Connect the external ventilation device and replace the N 2 three times. Under normal temperature stirring, inject 1.92mlG into the flask successively 4 PPI / acetonitrile solution, 40ml of acetonitrile, heated to 107°C for 20h. After the reaction was completed, the solid powder was filtered out, and the solid powder was washed three times with 30 ml of tetrahydrofuran to obtain a filtrate. The filtrate was distilled under reduced pressure to obtain an oily liquid, which was subjected to silica gel column chromatog...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com