Fuel injection device

A fuel injection device and fuel injection valve technology, applied in turbine/propulsion fuel delivery systems, combustion chambers, combustion methods, etc., can solve the problems of pilot injection valve combustion efficiency or poor ignition/flame stability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

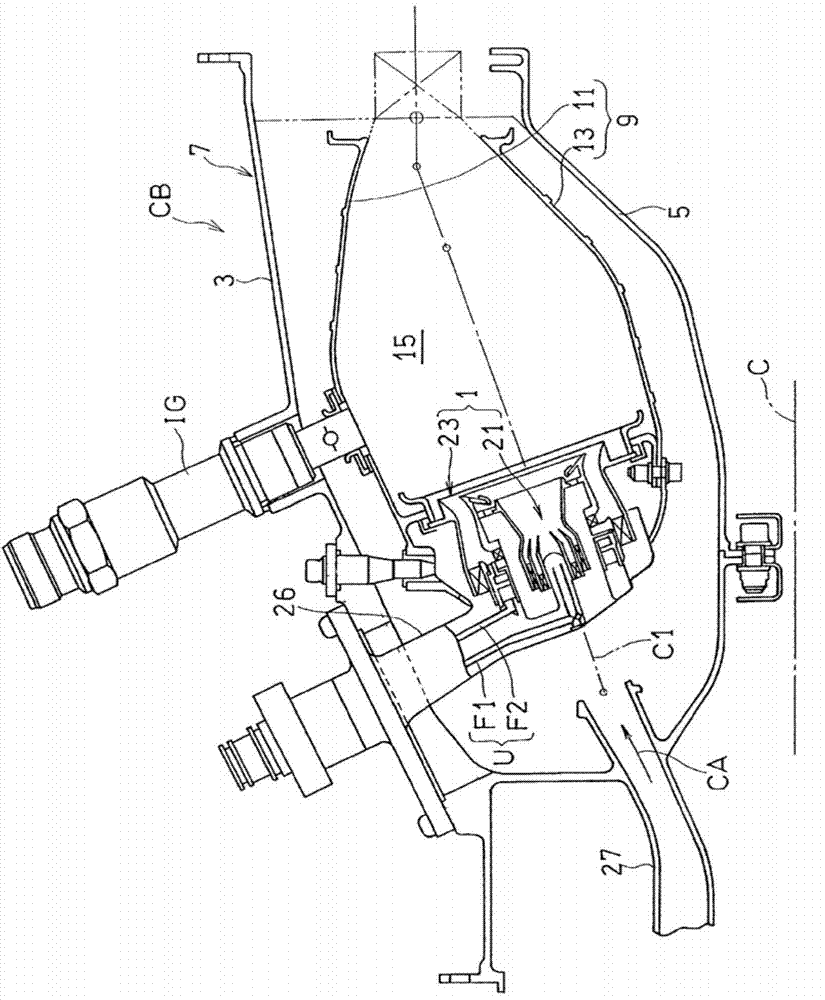

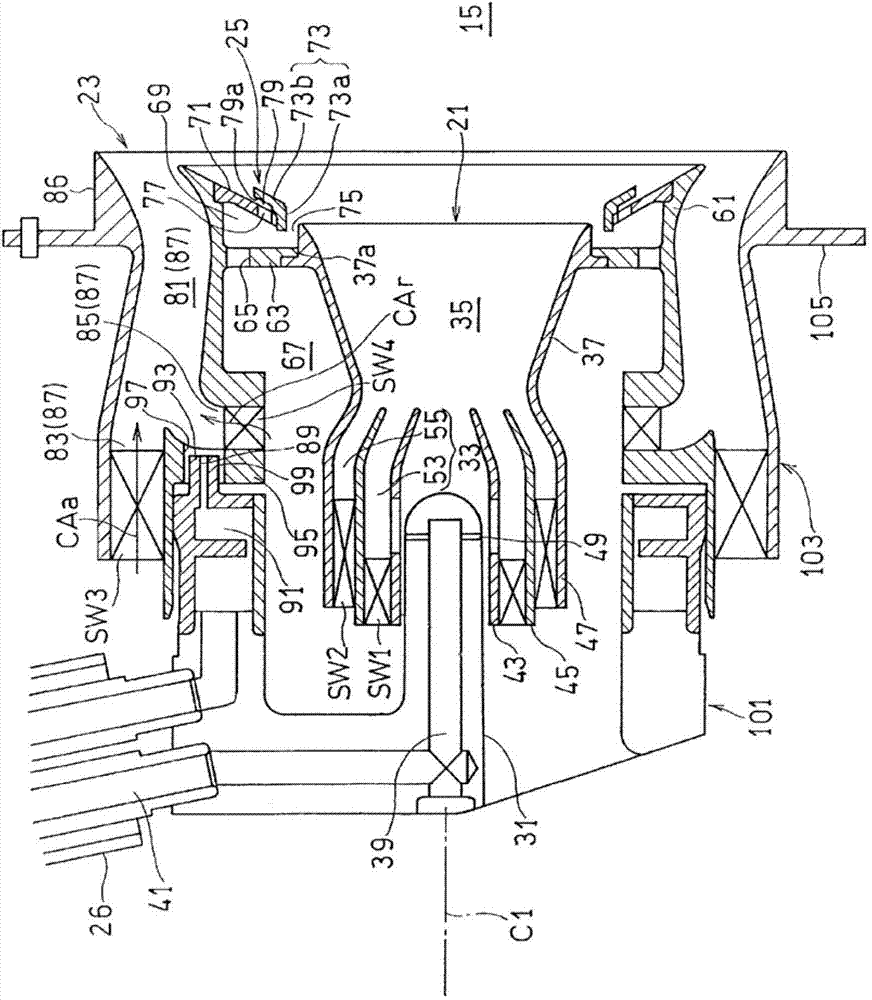

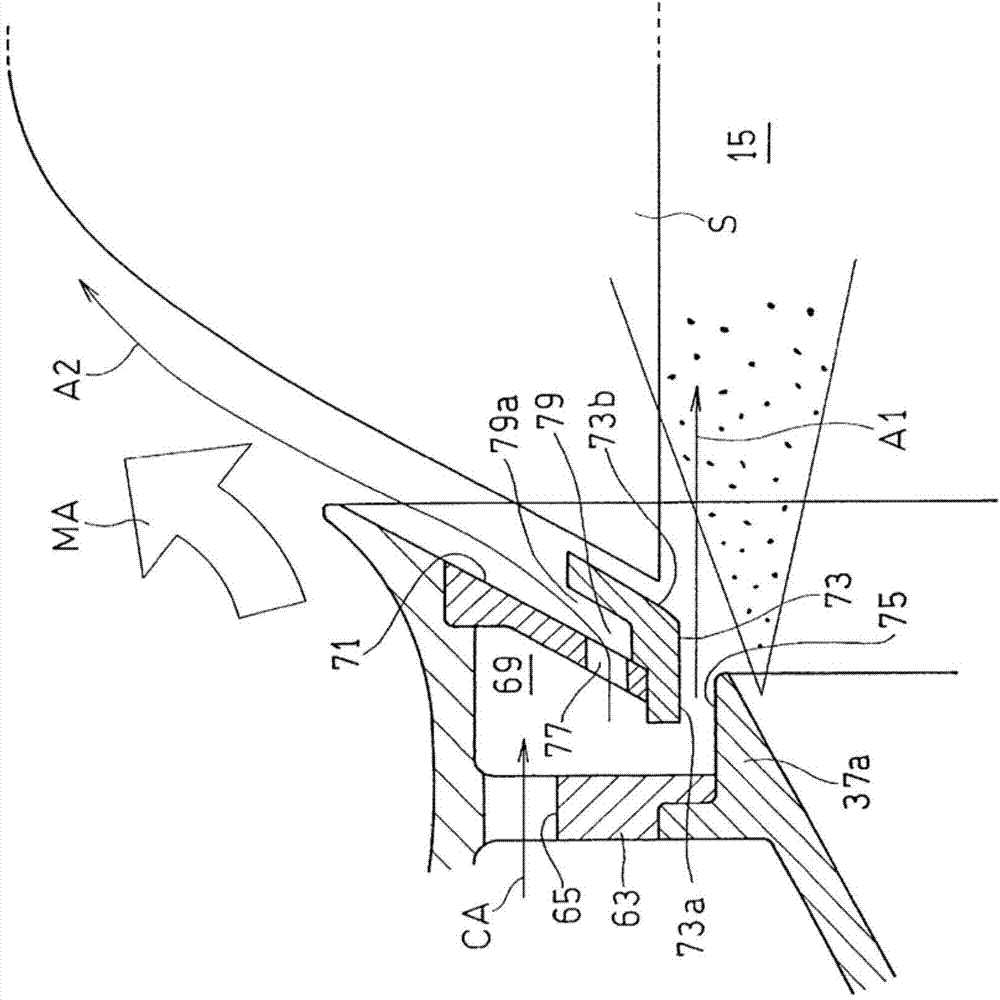

[0025] Hereinafter, preferred embodiments of the present invention will be described with reference to the drawings. figure 1 A combustor CB of a gas turbine engine including a fuel injection device 1 according to an embodiment of the present invention is shown. The combustor CB mixes and combusts fuel in compressed air CA supplied from a not-shown compressor of the gas turbine engine, and sends high-temperature / high-pressure combustion gas generated by the combustion to a turbine to drive the turbine.

[0026] The combustor CB has an annular shape, and an annular outer cover 3 arranged concentrically with the engine rotation axis C and an annular inner cover 5 inside it constitute a combustor case 7 having an annular inner space. In the annular inner space of the burner housing 7 , an annular combustion cylinder 9 is arranged concentrically with the burner housing 7 . The combustion tube 9 is composed of an annular outer liner 11 and an annular inner liner 13 arranged concen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com