Color sorter

A sorting machine and color technology, applied in sorting and other directions, can solve the problems of elevator blockage, motor damage, burnout, etc., and achieve the effect of low probability and preventing damage or burnout

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

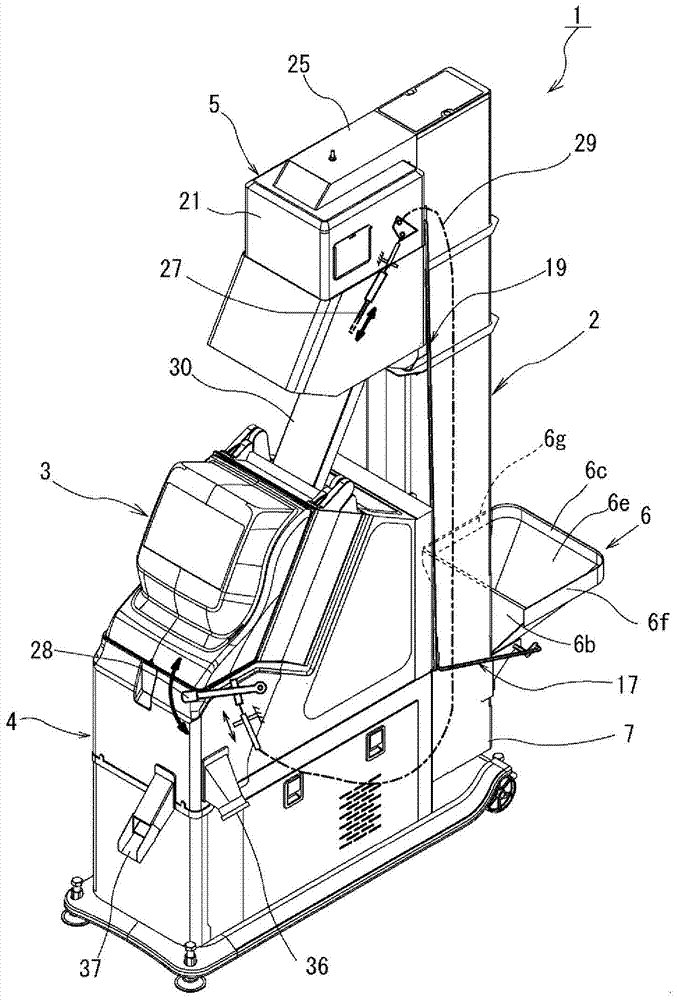

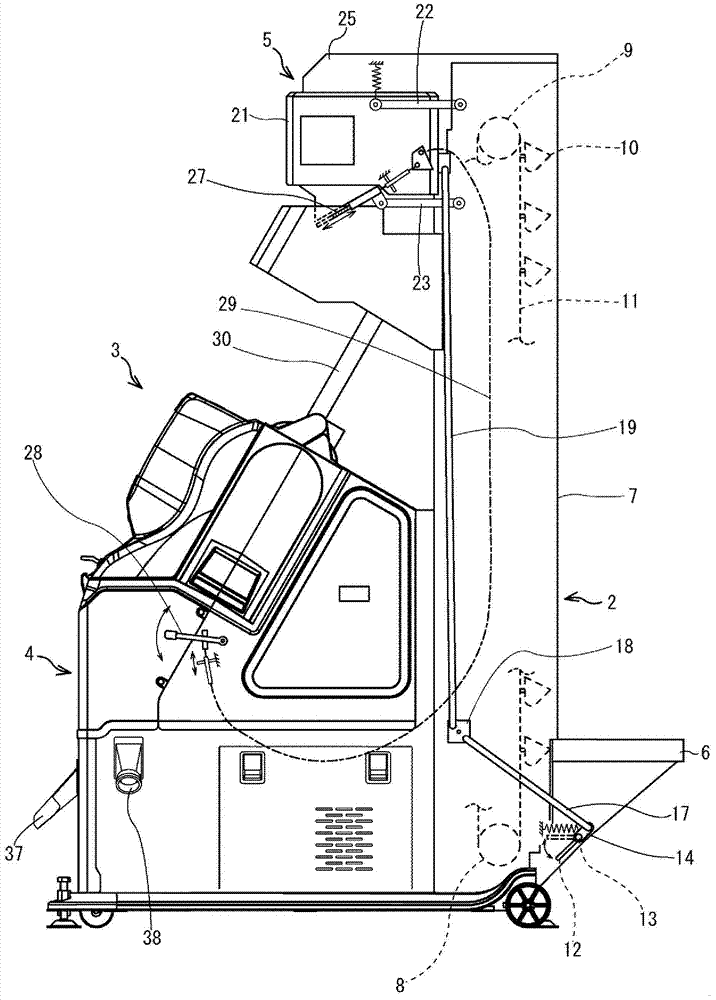

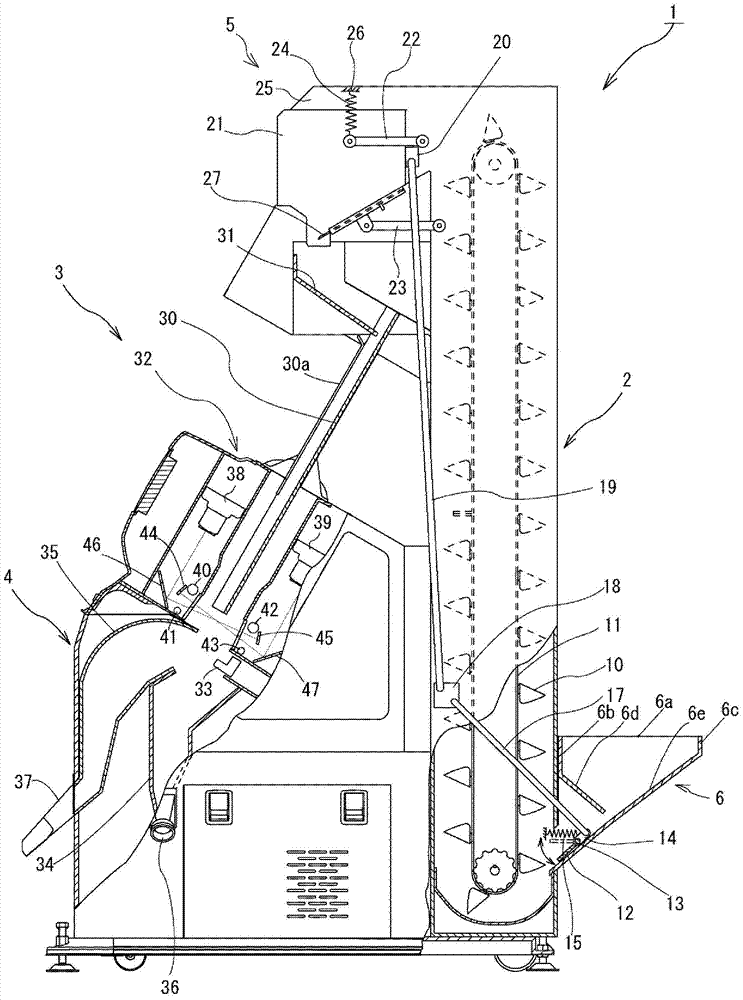

[0032] Embodiments of the present invention will be described below with reference to the drawings. figure 1 It is a perspective view showing the whole color sorting machine of the present invention, figure 2 is the right side view of the color sorter, image 3It is a partial cut-away sectional view of the color sorting machine, Figure 4 It is an enlarged view of the lower part of the lifting part, Figure 5 It is an enlarged view of the upper part of the elevator.

[0033] The color sorting machine 1 of the present invention can use grains, resin granules, coffee beans, and other granules as raw materials to sort good and bad products or foreign matter mixed with raw materials according to color.

[0034] Such as Figure 1 to Figure 3 As shown, the color sorting machine 1 of the present invention includes: a lifting part 2, which has an input funnel 6 for receiving raw materials at the lower part of the back side of the lifting part frame body 7; an optical sorting part...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com