Saddle type wire clamp and preparing method of saddle type wire clamp

A saddle-type, wire clamp technology, applied in the direction of mechanical equipment, pipe supports, pipes/pipe joints/pipe fittings, etc., can solve the problems of small elasticity, limited binding ability, and complicated parts, and achieve high elasticity, strong toughness, and preparation The effect of simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

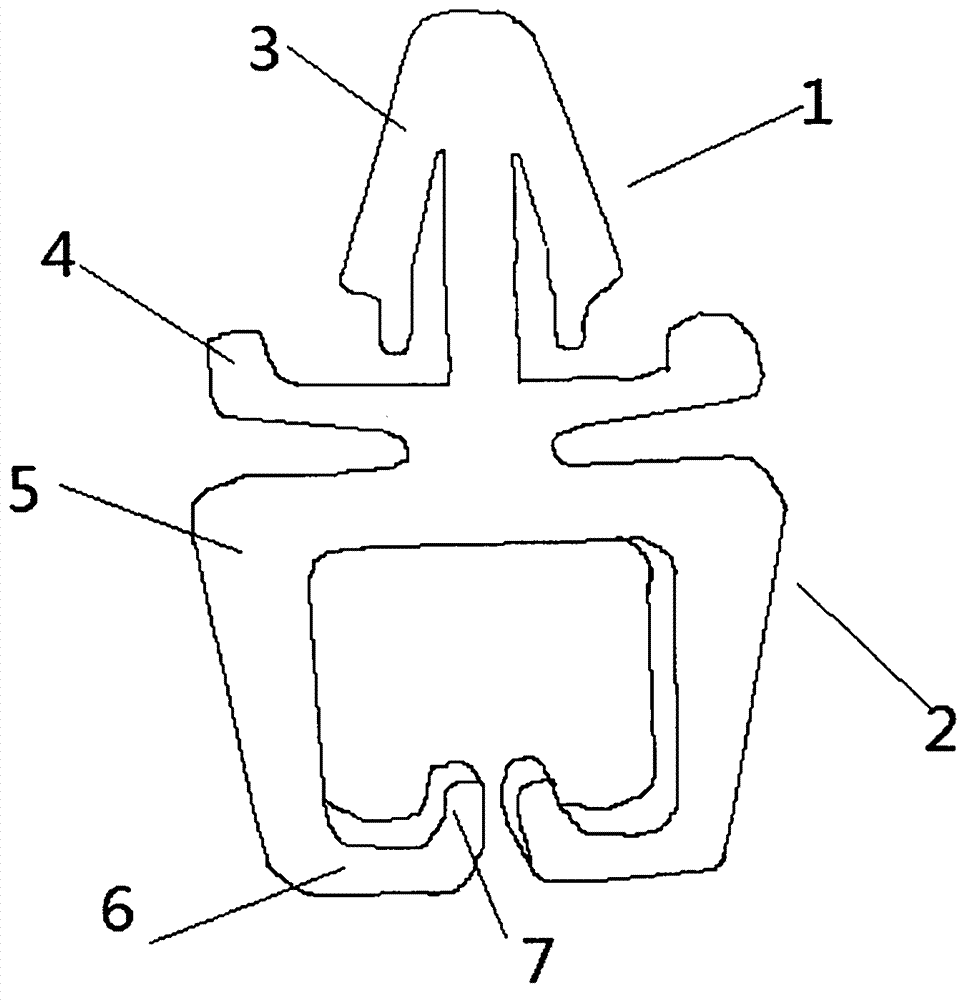

[0018] A saddle type clamp such as figure 1 As shown, it consists of a hanging head 1 and a card body 2. The hanging head 1 is provided with a pointed hanging head 3 and a horizontal hanging head 4. The card body 2 is provided with a first elastic part 5, a second elastic part 6 and a chuck 7 . The chuck 7 is a protrusion protruding into the card body 2 along the end of the second elastic portion 6 .

[0019] The wire clamp binds the wire in the wire clamp through the opening and closing of the first elastic part and the second elastic part. The pointed hanging head can be hung on the plate-shaped object, and the horizontal hanging head can be stuck between two rod-shaped objects. , so that the clip can be fixed on most fixtures, broadening its scope of application.

Embodiment 2

[0021] The preparation method of the saddle-shaped wire clamp described in embodiment 1 is carried out according to the following steps:

[0022] 1) Take 70 parts of nylon powder, 1.5 parts of molybdenum disulfide powder, 1.5 parts of polyimide powder, and 1 part of quartz powder according to the parts by weight;

[0023] 2) Put nylon powder, molybdenum disulfide powder, polyimide powder and quartz powder into a mixer and mix for 6-8 minutes, then put them into a granulator for granulation, and make granules with a particle size of 2-4mm for later use;

[0024] 3) Put the prepared granules into the injection molding machine. The temperature of the feeding port of the injection molding machine is 200-210°C, the temperature of the nozzle is 250-280°C, melt for 4-6 minutes, and then inject the melted material through the outlet of the injection molding machine In-mold, injection molding.

[0025] The tensile strength of the clamp is 430MPa.

Embodiment 3

[0027] The preparation method of the saddle-shaped wire clamp described in embodiment 1 is carried out according to the following steps:

[0028] 1) Take 70 parts of nylon powder, 1.5 parts of molybdenum disulfide powder, 1.5 parts of polyimide powder, 1 part of quartz powder, and 3 parts of firefly extract according to the parts by weight;

[0029] 2) Put nylon powder, molybdenum disulfide powder, polyimide powder and quartz powder into the blender and mix for 6-8 minutes, then add the extract of firefly, stir for 1-2 minutes, and then put it into the granulator for granulation to make granules Particles with a diameter of 2-4mm are reserved;

[0030] 3) Put the prepared granules into the injection molding machine. The temperature of the feeding port of the injection molding machine is 200-210°C, the temperature of the nozzle is 250-280°C, melt for 4-6 minutes, and then inject the melted material through the outlet of the injection molding machine In-mold, injection molding....

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com